Survive Product Complexity with MBSE

Model Based System Engineering (MBSE) helps us manage product complexity. Today’s complex products use a combination of electronics, software, and mechanics, which creates complex cross-product interactions that must be managed. To deal with this, systems engineers are trained to ask “Why?” so they can understand the reason behind decisions to make better cross-domain product decisions. (I did not know it at the time, but I was trained in college for the current conversations I’m having with my teenager which all begin with “Why?”). In this case, “Why do we need MBSE?” The short answer…to survive product complexity.

Coming out of engineering school, I went to work in the high-tech industry. One of the early projects I worked on was developing an auto-router for routing circuits for ~100k gate IC’s (out on the bleeding edge back then). We were quite proud of our work on circuit routing, taking around 6 hours per run with the best computing power we had at the time. We had the opportunity to brief one of the chief engineers, Dr. Charles Rose (one of the inventors of hardware description languages). Dr. Rose was complimentary of our efforts… but then added, “You’re never going to route a billion-gate integrated circuit in your life time that way.” My thought at the time was, “That crazy old Rose, what does he know? There is no way chips could get that big!” (I wasn’t a believer in Moore’s Law at the time). Gordon Moore and Dr. Rose were right:

- NVIDIA graphics cards now pushing supercomputer status with 21 billion transistors

- Largest gate count as of this writing is the 1 TB memory chips up around 2 trillion transistors

Back in July of last year, we celebrated the 50th anniversary of the first moon landing. The journey to the moon and back was made possible by one of the first integrated circuit guidance computers (~8400 transistors) with a massive 2k core and 32k rope memory.

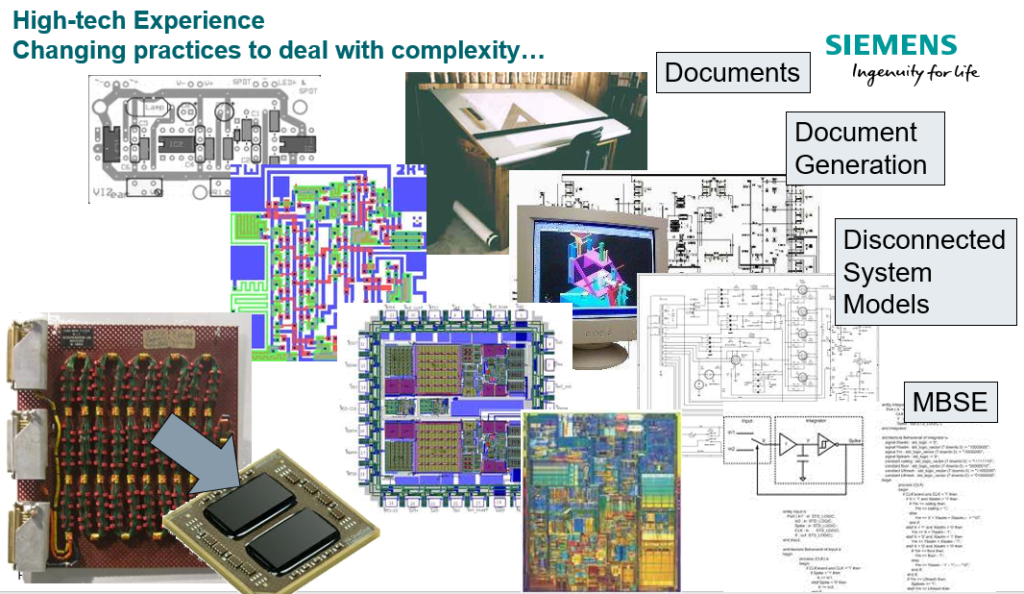

The guidance computer electronics were designed/laid out with tape on Mylar on a drafting table. As we moved to higher gate counts and greater levels of integration for more computing power, we had to scale our electronic development processes. We had to move away from drafting tables, to CAD layouts, to schematic capture systems with silicon compilers, and then to hardware description languages to scale the complexity.

We need to do the same thing for system engineering if we expect to survive the rising flood of complex electronics, with thousands of mechanical parts, controlled by millions of lines of code all working together (on top of millions of variations) in the products we are dealing with today.

So, the MBSE “why?” for your organization is survival!

I’ve also learned with my teenager you have about 30 seconds to get your point across (what’s called an elevator speech, it’s getting shorter, it used to be 118 seconds). According to recent studies, the attention span is getting even shorter for the internet-connected generation, so we’ve boiled the reasons behind MBSE down to two short-attention-span 120-second videos: “Why MBSE” and “Why System Modeling”.

Why MBSE is needed for your product development survival?

- Product complexity is growing

- It’s impossible to comprehend/manage it all on your own (even adding more engineers to the problem)

- If you don’t manage it, you will have problem escapes that will cost you lots of time/money

- You need MBSE tools/methods with PLM to help manage it all

Electrical engineers figured this out already and went to higher levels of abstraction to keep up. Systems engineers will need to do the same because it is at the combinations of systems/sub-systems where the big problems happen.

We hope these “Why” videos will help you explain to short attention-span friends/managers/accountants why you’re investing in MBSE.

We have more model based system engineering articles to read within the MBSE blog tag. You can also get more info at our Siemens Industry Software web site on MBSE and integrated System Modeling.

UPDATE: There’s a new whitepaper on integrating Systems Engineering/MBSE with your product lifecycle available for download. Systems Engineering is more than just putting tools in place, it requires changes in people, processes, and tools to be successful.

Regarding people, we have also posted a second whitepaper on integrated MBSE training/education as well as a integrated MBSE training curriculum that is now available. We will cover both of these topics in an upcoming integrated MBSE webinar, Check out the whitepapers and the webinar for advice on implementing MBSE in your organization.

-Mark Sampson