Siemens PLM Digital Thread Is Aircraft Manufacturing Enabler

Kobi Levi can tell us about what air framers (airplane manufacturers like Boeing and Airbus) really need from the SPLM solution offering. As he puts it, we need to know what’s ‘causing them to lose sleep’ in their search for innovative solutions to the pressures they’re facing on the manufacturing floor.

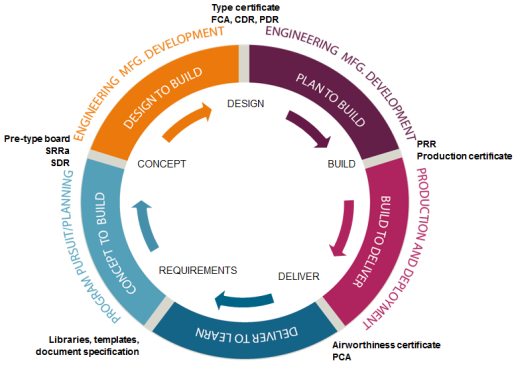

So Kobi cleared time in his busy schedule of bringing the SPLM technologies and solutions to the digital manufacturing market. He put together a video to tell a sort of ‘day in the life’ about the air framers challenges. And in extensive detail, he portrays the “360” sweep of their work phases from design to manufacturing and relates each stage to the comprehensive SPLM offering.

Kobi describes a plan to help users meet their needs:

- Planning of preliminary product design / preliminary planning for manufacturing

- Planning of actual manufacturing and processes

- Execution on the factory floor

The last 10 years have seen many advances in airplane engines and in the use of composite materials. Today the air framers, both commercial carrier manufacturers and private jet makers, are all experiencing an increasing backlog in orders.

Factors in recent years that have contributed to this spike in orders:

- Sharp rise in airplane fuel

- Commercial carriers’ decision to replace their aging stocks of aircraft

As a result, manufacturing lines have become backlogged, and the air framers now want to introduce more automation, keep to tight budgets and manufacturing schedules as they aim to build more fuel efficient airplanes. For instance, they want to speed up part riveting by moving away from the traditional manual methods.

More generally, aircraft manufacturers will benefit by adopting tools which provide the digital thread for the phases in the digital environment for product and manufacturing planning and the actual manufacturing process itself.

The main benefit of the digital thread in airplane manufacture is the seamless flow of information from one application to the next throughout the manufacturing process. With this data flow, everyone knows for sure that they are working on the most up to date information.

The digital thread also adds value by allowing the manufacturer to trace the “genealogy” of materials used, which assembly methods and tools were implemented, and to track down defects that may have been introduced earlier – perhaps a part fell during a fastening procedure, but was deemed fit at the time to continue on the assembly line. And later on, if a recall was mandated, a cause and effect trace was able to identify the irregular incident on the shop floor.

SPLM provides the tools and processes to validate new concepts for products or parts, that they will satisfy the mission, even as they allow the customer to create product and production information for each concept option at an early stage and store and maintain that information as the concepts mature.

Stages supported by SPLM tools:

The product designer, using NX CAD, develops the CAD models and the eBOM for each concept.

The product designer, using NX CAD, develops the CAD models and the eBOM for each concept.

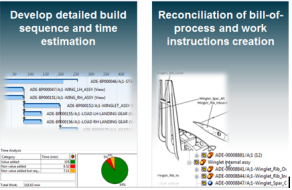

The manufacturing engineer may reconcile the eBOM and the mBOM and verify that the engineering change is applied to the mBOM completely and with the right context and configuration.

The engineer can generate optimized processing plans for the composite materials using NX, Fibersim and Teamcenter Manufacturing.

The tooling engineer uses the classification application search for existing tools that could be suitable for specific operations.

The tooling engineer uses the classification application search for existing tools that could be suitable for specific operations.

Now the BOP and the work instructions are finalized and released, and MRO – Maintenance, Repair and Overhaul protocols are much easier to manage in the SPLM digital environment.

The concept of the Digital Twin is the ability to validate changes on the factory floor in the digital environment before implementing them.

Kobi’s elaborate video drills deep into the air framers’ manufacturing challenges, and provides clear explanations of how the Siemens PLM portfolio fits the full range of their manufacturing cycle needs.

If you’re an executive, pre-sales engineer or end-user, you’re invited to check out Kobi’s video training to learn more for yourself how the SPLM solution is a practical vision for air framers’ manufacturing business flow.