Tecnomatix 13 – What’s New?

The Tecnomatix® portfolio of digital manufacturing software solutions empowers manufacturers to do remarkable things that allow them to realize the amazing products their customers need right now. The latest Tecnomatix release from Siemens PLM Software, including Process Designer 13, Process Simulate 13, Plant Simulation 13, RobotExpert 13 and Factory 2017, continues to deliver advanced technology in the areas of planning, simulation and production. Our software is designed to help manufacturers not only plan and validate manufacturing processes and optimize complete systems prior to production, but to also know what will happen when those processes and systems do not perform as expected and how they need to respond to bring them back online when production stops. In this latest release of the Tecnomatix portfolio, new capabilities deliver key benefits to specific industry users, offer enhanced solutions in areas such as factory layout optimization, robotics and human simulation, and help to improve the overall user experience. We think you’ll be impressed with what Tecnomatix can do for you.Please let us know what you think in the comments section below.

Tecnomatix benefits and features at a glance

-

- Dedicated industry solutions for Automotive & Transportation, Aerospace & Defense, Heavy Equipment Machinery, Consumer Packaged Goods and Electronics & Semiconductor industry users.

-

- New capabilities for digital factory layout optimization, robotics, human simulation and more.

-

- Significantly improved user interface experience, interaction, and ease of use.

Powerful new tools that you’ve been waiting for

Robot cable physical behavior and motion simulation tools

Automotive and transportation and heavy equipment machinery manufacturers are heavily dependent upon robotic systems to deliver the innovative products that their customers demand. These robotic systems require planning and programming to allow them to operate as efficiently as possible and to perform as required. Such advanced robotic systems require cabling that is often difficult to account for during programming and execution and can lead to serious issues during production if not handled correctly.

How do you recover quickly when a cable malfunction happens in production? The new cable add-on to Process Simulate 13 gives operators the opportunity to know what will happen and how to solve the problem by allowing users to simulate robot cable physical behavior and motion.

This new cable functionality enables users to create and edit cables, define their dimensions and physical characteristics, to add hooks and connection points, to perform realistic cable simulation and to analyze the cables for coiling, excessive extension force and collision within the production environment. Upon the identification of an error, users can employ the software to regenerate the cable with an alternative cable shape.

Paint and spray path planning, coverage simulation and analysis tools

Tecnomatix now features paint and spray path planning and coverage simulation tools ideally suited for automotive and transportation and aerospace and defense industry users. We now give users the ability to perform path planning for spray applications and to gain an understanding of the coverage through simulation and visualization.

The Continuous Process Generator has been enhanced to support the coverage pattern process. Users can now create a continuous operation with a coverage pattern in an intuitive and easy way. With the tool, users draw a reference curve on a part and create a pattern by duplicating the curve with constant offset strokes.It is possible to preview the pattern and modify it easily before creating the operation. The new operation can be used for paint, polishing, coating, spraying or many other processes that require covering a surface while adding or removing material.

The software also offers the new capability to analyze the number of paint layers/strokes affecting a point on a surface (mesh point). When running the simulation, each layer is clearly designated by a configurable color. The Paint and Coverage settings allow users control regarding which surfaces are used for coverage simulation, displaying or hiding the coverage map during simulation, the display of a ghost spray applicator, such as a brush, and the display of a stroke map that indicates multiple strokes over the same area of the generated mesh.

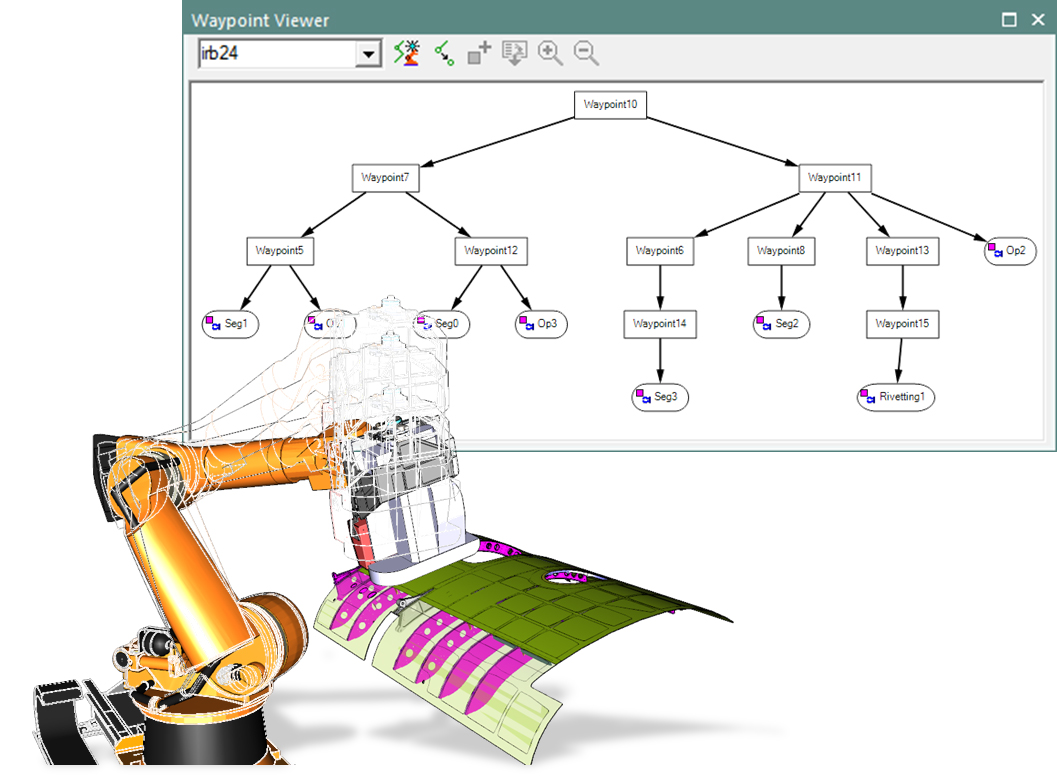

Waypoint planning and viewing tools

Aerospace and defense industry users will certainly benefit from the new waypoint capability for improved planning and programming. The new Waypoint Viewer enables users to quickly and easily configure collision-free paths for robots through the management of waypoints, which are used to define approach and escape paths between operations commonly used in drilling and riveting applications. These waypoints and the resulting operation structure that includes them is supported in both simulation and offline program download.

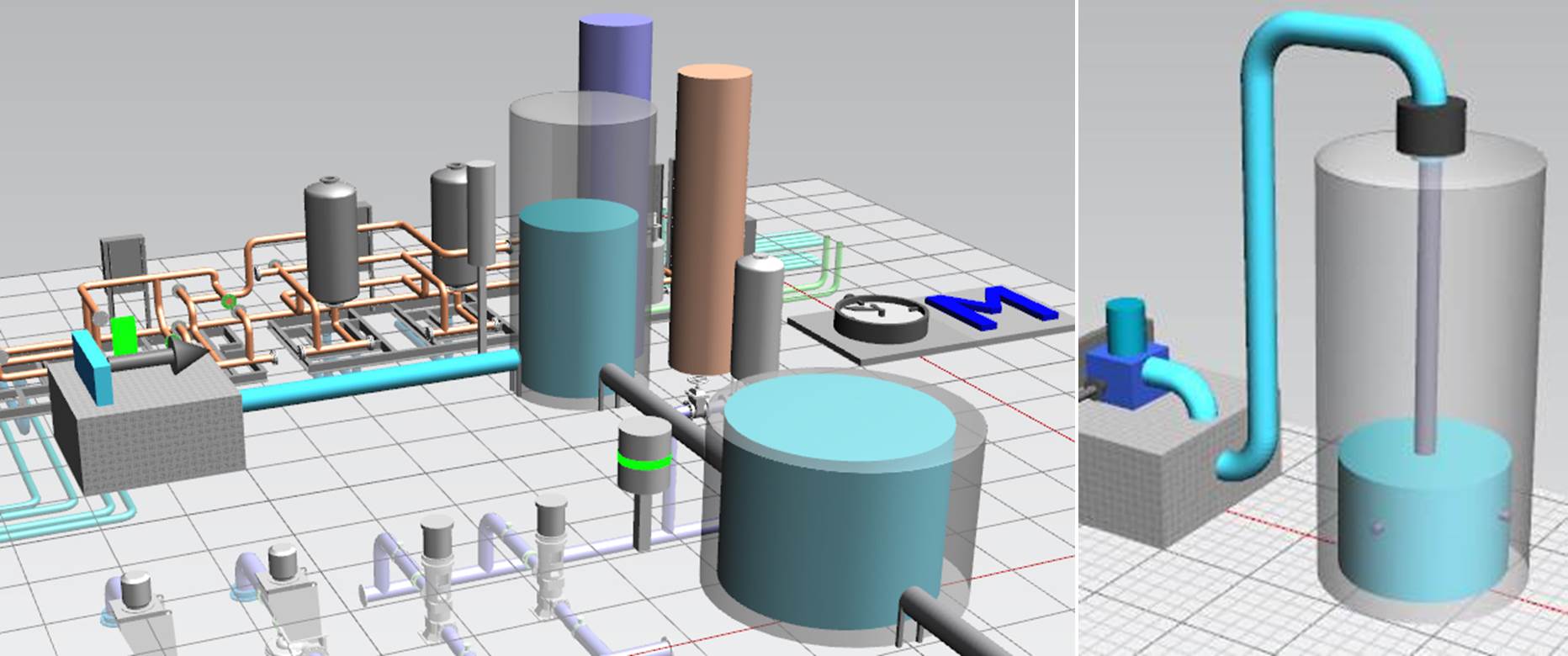

Fluid process production performance simulation and throughput tools

Plant Simulation now features additional object handling tools to better simulate and assess production performance and throughput for processes involving fluids for consumer packaged goods and other process industries. These are out-of-the-box tools that make it much easier to simulate the transport of fluids through pipes, including both horizontal and vertical piping systems, and what will happen when those fluids are mixed in tanks and then distributed to downstream processes.

Operator free walk path simulation tools

Electronics and semiconductor industry users, and others that regularly deal with manual operations, can better address the allocation and utilization of manual labor with operator free walk path planning and simulation tools. With this new Plant Simulation capability, it is no longer necessary to specify the operator footpaths required to move an operator from one point to another, drastically reducing the time it takes to simulate manual operations involving walking. The new capability provides automatic recognition of machines and equipment during path planning, user definable non-walking areas to control where the operators are allowed to move and automatic shortest path calculation for walking between targets on the production floor.

NX Line Designer and Teamcenter Manufacturing integration tools

Added to Tecnomatix in this release is enhanced interfacing between NX Line Designer and Plant Simulation for better production layout optimization. This new capability, focused on the automotive and transportation and heavy equipment machinery industries, enables users to take a layout from NX Line Designer directly into Plant Simulation with the data that is needed to create an initial simulation model, greatly speeding up the process of optimizing the layout for production throughput and material flow.

Teamcenter® Manufacturing Access, developed on top of the Active Workspace platform, is released for the first time in this version for better coordination of resources and operations between Teamcenter Manufacturing and Process Simulate. It enables simulation engineers to perform all their tasks using just one application, Process Simulate. Tools such as Load Study and Classification Search were added to Process Simulate for accessing and loading Teamcenter data directly, improving usability and reducing dependency on the Teamcenter Rich Client.

New usability enhancements and tools

This latest release offers several new usability enhancements and tools to make Tecnomatix solutions more enjoyable to use, addressing ease of use, improved visualization, and performance. Tecnomatix is now even more fun to use!

Now, when users open Process Designer, Process Simulate or RobotExpert, the application displays a new Launch page. The Welcome and What’s New tabs on this page provide a variety of useful information about new features as well as easy access links to recent files with clickable Favorite ranking stars, icons to open or create studies, indication of the current system root location, access to the Options dialog and links to various related social media channels. There is also a linked tab that opens the Siemens PLM Community site for quick access to further information in blog posts and knowledge base articles.

Additional usability enhancements and tools include more common user interface (UI) theming across applications, ribbon menu interfaces, simulation performance improvements, multiple graphic window viewing and multiple language support.

Additional software features and tools

Process Designer 13

There are several new enhancements in Process Designer related to Robcad data migration, Pack and Go improvements, AutoCAD® certifications, Ticon integration and the handling of alternatives.

Process Simulate 13

In Process Simulate, the export to web function and point cloud data integration using Bentley Pointools have been improved.

Process Simulate Robotics improvements cover expanded dual arm robot support, updates to the Automatic Path Planner and the addition of skip welding operation creation to the Continuous Process Generator.

Process Simulate Commissioning now offers support for virtual commissioning using the OPC Foundation’s new OPC Unified Architecture (UA) protocol.

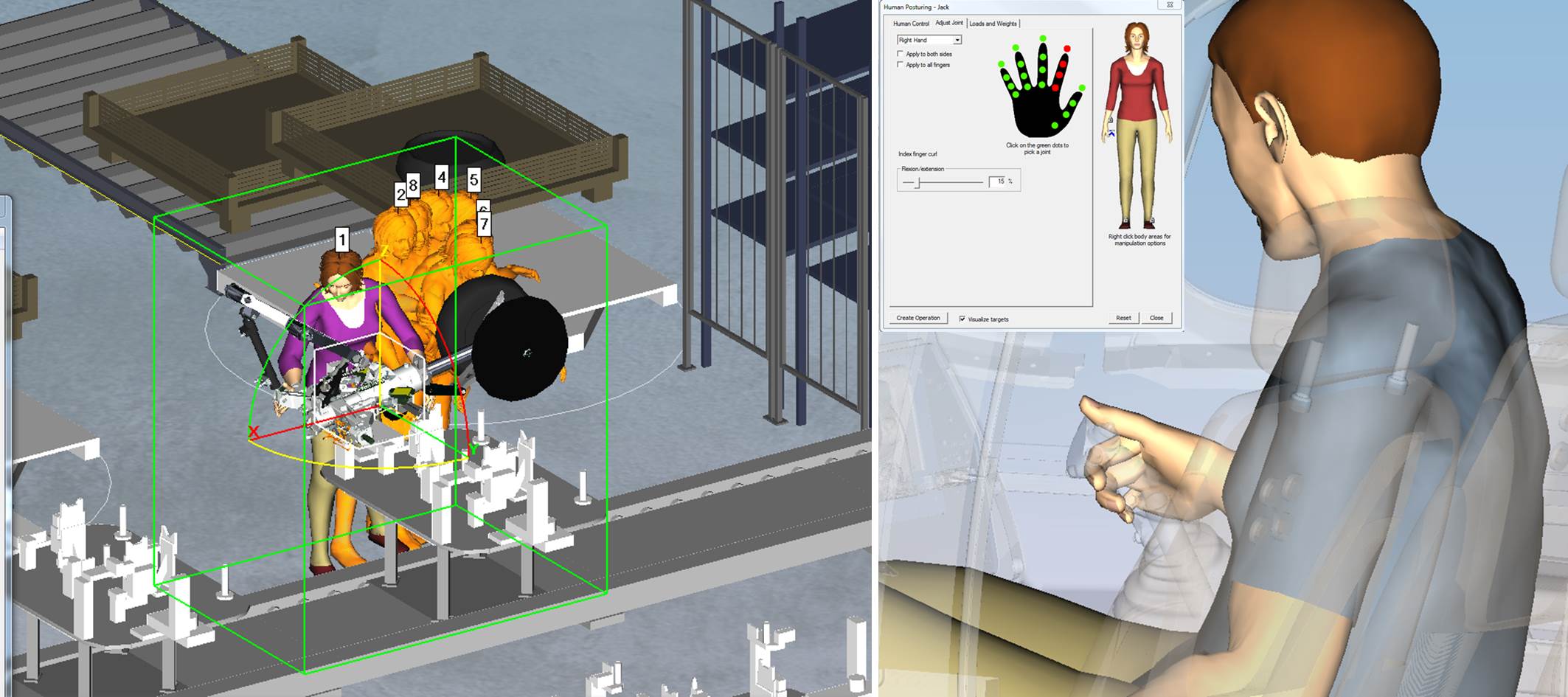

Process Simulate Human now makes simulating human tasks even easier and more powerful. Task Simulation Builder (TSB) enhancements allow you to more quickly control motion specifics as well as reuse the edits when running ‘what-if’ scenarios with different sized figures. Motions captured from motion tracking systems can now be incorporated directly into TSB simulations. Additional manipulation controls for posturing, including a highly efficient interface for manipulating the hand, have been added to accelerate realistic posturing of the figures. The interface to the Ergonomic Analysis Worksheet (EAWS) has also been improved to make reports more concise.

Plant Simulation 13

Plant Simulation now provides an enhanced SimTalk 2.0 scripting language that greatly simplifies the modeling process for objects, libraries, models and methods, and offers an integrated compiler to quickly and easily convert between the 1.0 and 2.0 syntax. OpenTools geometry importers have been adopted for additional 3D CAD data format support and point cloud data integration allows for the high-performance use of 3D laser scan data directly in 3D simulation models. Additionally, enhanced drag and drop conveyor and line modeling, Microstation® and AutoCAD layout import improvements, virtual commissioning support of OPC UA and several other modeling and usability enhancements are delivered with this release.

Factory 2017

The latest FactoryCAD, FactoryFLOW and In Context Editor (ICE) product releases include support for AutoCAD 2017, Teamcenter 11.2, and Microsoft® Windows® 10, Office® 2013 and Office 2016. Usability enhancements include improved toolbar and menu loading behavior, better backward compatibility, enhanced direct Teamcenter resource access tools and the inclusion of a tutorial inclusion and Tecnomatix public community link directly in the ribbon menu. Based on strategic customer requests, block manager migration, FactoryFLOW component tree expansion and part routing reordering were implemented in this release.

RobotExpert 13

This release of RobotExpert includes skip welding operation creation to the continuous process generator.

Other

Tecnomatix versions can now be installed side-by-side on a single system for easier transition from one version to another, new certifications are available for various CAD systems, including Catia® and AutoCAD, as well as for Windows 10 and Office 2016, and there is a new application for licensing setup and maintenance, and an improved documentation interface for online help.

Many other new features can be found in the various product release notes provided with the software. And keep an eye out for additional community posts discussing these and other new features and tools in more detail.

Yours in digitalization,

![]()

(on behalf of the Siemens PLM Manufacturing Engineering Software team, with special thanks to @Stephanie Aldrete)

![Automation World features Tecnomatix Process Simulate: the essential software for virtual commissioning [ARTICLE]](https://blogs.stage.sw.siemens.com/wp-content/uploads/sites/7/2024/03/automation-world-process-simulate-2-395x222.png)