Virtual commissioning made easy with Process Simulate VC Lite

Virtual commissioning helps deal with today’s manufacturing automation challenges.

Today’s system and automation integrators are facing many challenges such as frequently changing customer demands, ever shorter product lifecycles and reduced product launch times. New technologies such as autonomous mobile robots, advanced robotics enabled by machine learning and vision-based systems play more and more of a key role in realizing the flexible production systems fit to handle these challenges. Navigating these challenges in a profitable manner – especially while the effects of COVID-19 are still disrupting world markets – is crucial for a system integrator.

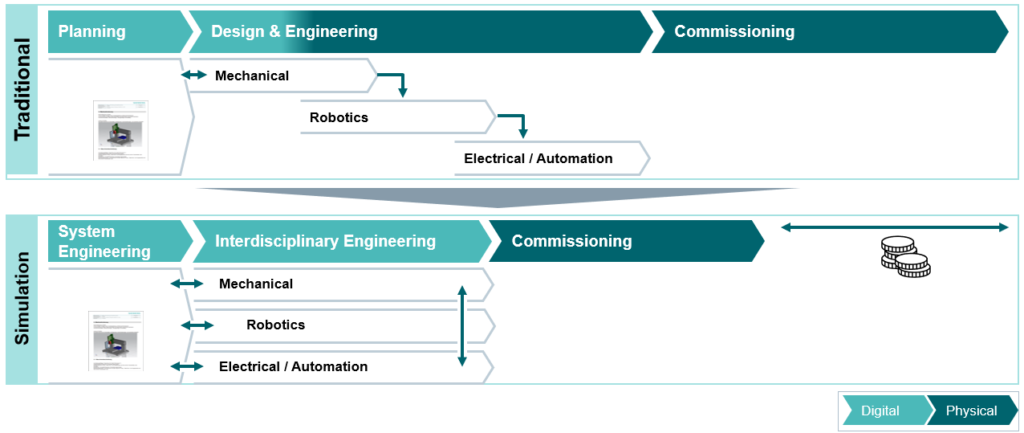

Given all of this, a particularly critical and sensitive phase must always occur prior to starting production. This phase is when deliveries from mechanical engineering, electrical engineering, and controls engineering come together for the first time to form the production environment (machine or system) and, with the digital twin, such integration is achievable also in a virtual environment.

What is virtual commissioning?

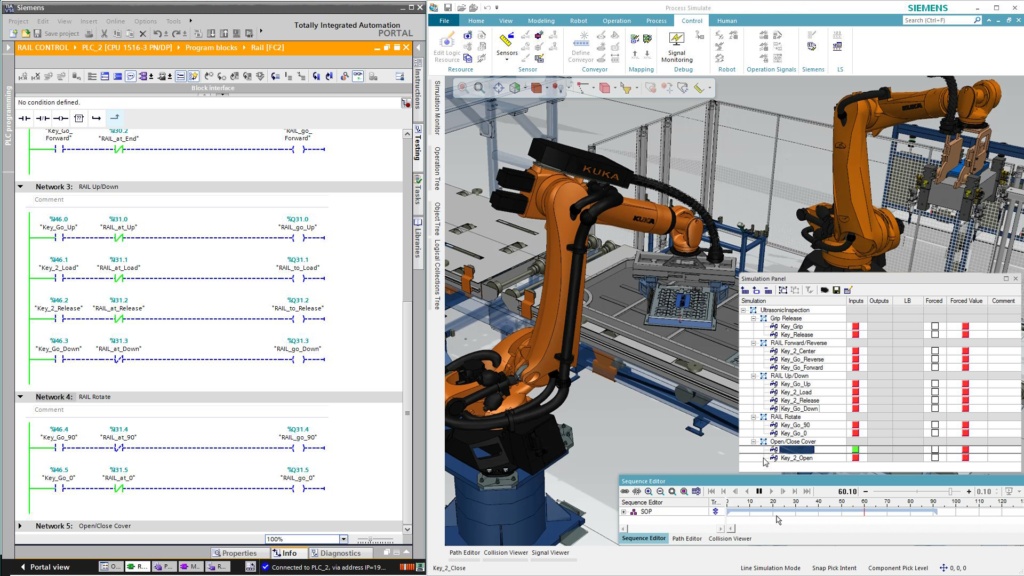

Virtual Commissioning is the design and testing of a virtual model of a production facility or machine. To achieve this, 3D simulation is used to create a digital copy of the facility which is then typically connected to the automation system – a physical PLC (hardware-in-the-loop) or a soft PLC (software-in-the-loop) such as PLCSIM Advanced – allowing to virtually test every aspect of production before it starts or prior to making changes to it. For example, robots can be put into virtual operation, tested, and optimized before transferring the programs to the actual facility, and new technologies can be integrated and validated.

Benefits of virtual commissioning

- A common virtual space for mechanical, electrical, controls, and systems engineers to collaborate and develop simultaneously, rather than serially, at an early stage of the production system lifecycle.

- An environment to perform early testing of mechanical behavior as driven by controls, early testing of control logic through observation of machine or system reaction to PLC output, and PLC reaction to machine or system input.

- In-depth simulation of the entire production system with all its components, allowing ramp-up or reconfiguration with minimal production stoppages.

- Shifting of commissioning off the production floor, reducing the requirement for on-site personnel during the final commissioning phase from several weeks to a few days, cutting costs significantly.

- A realistic validation of a machine or system allowing for identification and resolution of errors, as well as optimization of programs, by visualizing such things as improper material flow or an incorrect sequence of events.

Process Simulate VC Lite

Is virtual commissioning for enterprises only? Certainly not! With Process Simulate VC Lite, Siemens brings virtual commissioning and robotics to small and medium businesses from different industries like electronics, industrial machinery, automation production system integrators, consumer goods, and others.

VC Lite provides users with full functionality for development of a digital twin, including:

- CAD import, and kinematics and physics-based modeling

- Layout design and management tools

- Trajectory planning and offline programming applications for all leading robot vendors

- AGV application for motion planning and validation of autonomous vehicles

- Virtual camera simulation for vision system validation and optimization

- Advanced connectivity to additional tools for virtual commissioning: robot vendor RCS modules and virtual robot controllers, hardware-based and software-based automation systems, AGV fleet management systems, vision systems, and open connectivity for user defined applications.

—–

Interested in Process Simulate VC Lite? Start your 30-day trial today!

Find your local partner today.