Commissioning Your Plant Material Flow – Part 1 – The Digital Twin

Authored by Noam Ribon, Senior Consultant, Siemens PLM Software

This blog will help you better understand our Tecnomatix Plant Simulation application and why it is a foundational component of the broader Production Digital Twin architecture.

This blog will help you better understand our Tecnomatix Plant Simulation application and why it is a foundational component of the broader Production Digital Twin architecture.

Becoming familiar with Plant Simulation will help you understand how and why it lends itself well to Commissioning Plant Material Flow and related scenarios.

In the second blog, we will dive into one of the hottest topics of the Production Digital Twin: Virtual Commissioning of your Plant Material Flow.

You will find our Plant Simulation on desktops of professionals in multiple industries. Automotive, solar cell production, electronics, airports/transportation, battery production, glass production, and ship building. Its primary use is ensuring the correct investment levels for Production: CapEx (Capital Expenses – machines, space) and OpEX (Operational Expenses – mainly labor). While doing so, professionals run multiple Production scenarios to ensure optimized production with those investments. There is one reason for that: Maintain price competitiveness, and to ensure never falling on delivery commitments. In some industries, decisions will not be made without consulting Plant Simulation first.

To prove my point, here are testimonials from organizations using Plant Simulation:

Production throughput was increased by 40 percent. Production costs could be reduced by 30 percent. (Heavy industry).

Plant Simulation helped us avoid significant capital investments and operational costs. (Energy Power Transmission)

We could halve our inventory in the warehouse. (Industrial equipment).

More efficient production line with less waste. (Life Sciences).

Reduced cycle times by up to 66 percent. (Automotive T1).

The reasons decisions based on Plant Simulation produce such results are attributed to the following:

First, the software enables maintaining of a Digital Twin, which means its Virtual models closely reflect your Production environment. Today we would say the Digital Twin closely reflects the Physical Twin.

- Visually, with CAD geometry or laser scans; behaviorally, adjusting behavior with data from the Physical Twin (SCADA, IIoT, OEE); and, operationally, driven by HiL (Hardware in the Loop or SiL (Software in the Loop) automation (known as Virtual Commissioning).

Second, Plant Simulation software offers efficient modeling integral with collaborative clarity, so investigations of scenarios can start fast, and consensus moving forward can be achieved rapidly. This is due to its close to reality visualization which helps convey concepts crisply.

- Smart 2D with integral 3D (sketching in 2D will generate 3D; creating a layout in 3D will generate its 2D counterpart). Geometry is available OOTB, or can leverage CAD data.

Third, it is fast, dependable, accurate and offers thorough decision support

- Visual analysis, automated, smart utilities (from Data-Fit, Multi-layered Experiment Manager all the way to Neural Network Analysis and Genetic Algorithms) and integrated reporting are integral to the application

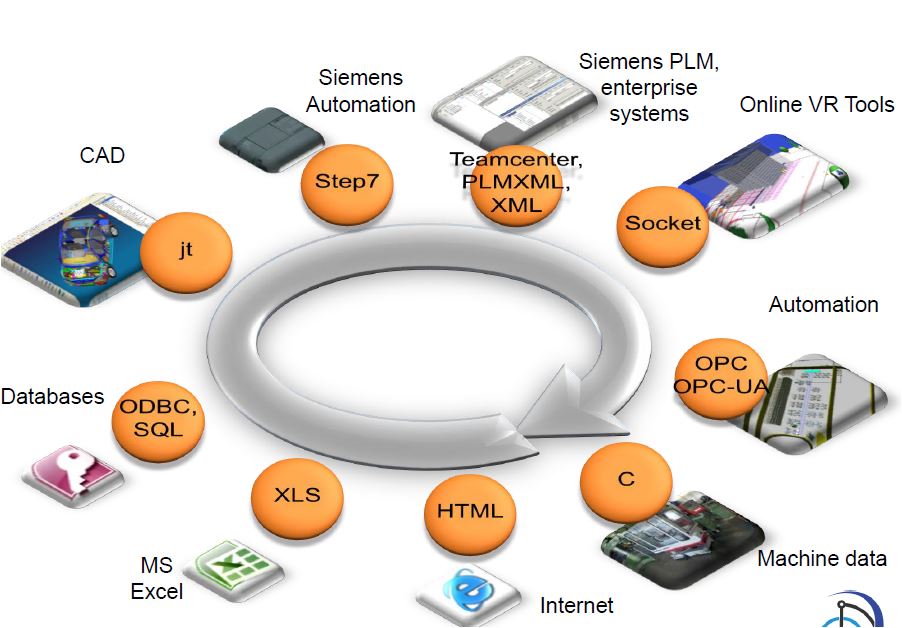

And last, Plant Simulation software offers support for common digitalization interfaces including integration to Teamcenter, the Digitalization Backbone.

- The Digital Twin, now more than ever, is part of an ever expanding digitalization network, and must be connected to it through various Digital Threads. This tight connection allows for speed and accuracy.

Various Digital Thread enablers of Plant Simulation

Various Digital Thread enablers of Plant Simulation

Digitalization with Siemens PLM Software applications

Digitalization with Siemens PLM Software applications

In Summary

Plant Simulation provides the ability to create complex digital models in an efficient and productive manner. Through its object orientation, hierarchy and inheritance these models remain clear, concise and predictable throughout a product’s life cycle.

In our next blog, we will discuss how Plant Simulation lends itself to Commissioning Your Plant Material Flow. Stayed tuned for Part Two: Virtual Commissioning

If you learned something and enjoyed this post, please leave a comment below.

Read part two in this blog series here.

![Automation World features Tecnomatix Process Simulate: the essential software for virtual commissioning [ARTICLE]](https://blogs.stage.sw.siemens.com/wp-content/uploads/sites/7/2024/03/automation-world-process-simulate-2-395x222.png)