Discover what’s new in Plant Simulation 2302

Next-level factory simulation and optimization with Tecnomatix digital manufacturing.

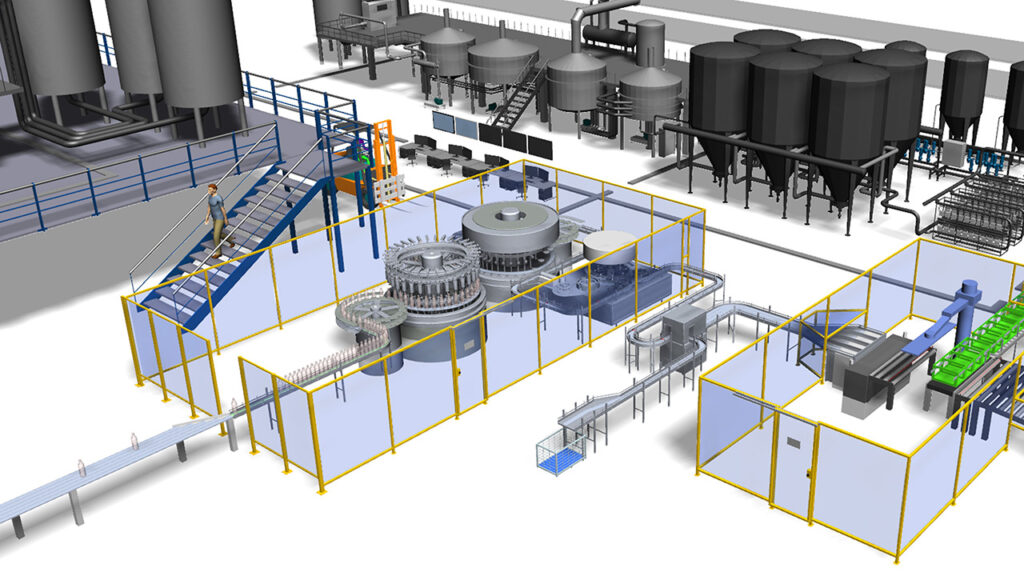

Plant Simulation in the Tecnomatix® portfolio of digital manufacturing software optimizes manufacturing by modeling and simulating scenarios for production systems and their processes. With Plant Simulation you can build simulation models reflecting your real factory in a digital twin model. The simulation models run fast, are reliable along a virtual timeline and can generate key performance values in the same way that your real production system does. According to those results, you can make your performance improvements and optimizations in early planning phases, when the production system is not yet built or available.

Plant Simulation product development covers several areas in parallel. We continue to maintain a leading position in the market of material flow and logistics simulation. Additionally, we are working on topics like PLM collaboration, virtual commissioning and web- and cloud-based use cases for material flow simulation. This blog post provides an overview of Plant Simulation enhancements in version 2302 released in February of this year.

We are happy to deliver this new release to you.

You don’t have Plant Simulation software?

Highlights from Plant Simulation 2302:

Material flow enhancements

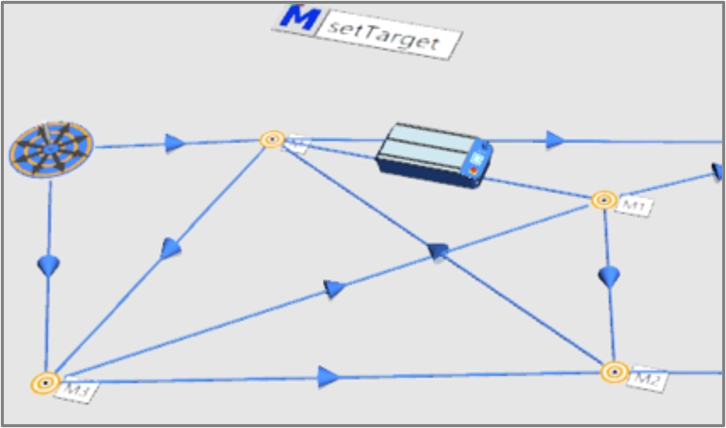

In Plant Simulation 2302, we complete the set of functionalities introduced in previous versions for modelling and simulation of autonomous guided vehicles (AGVs). You now can easily connect AGV driving markers to create a network and use the automatic route calculation for AGVs that are driving between those markers. Once you define a destination marker, an AGV calculates the shortest path to the destination and drives autonomously along this path to the destination. This way you can easily implement your own AGV fleet manager just by assigning the AGV destination.

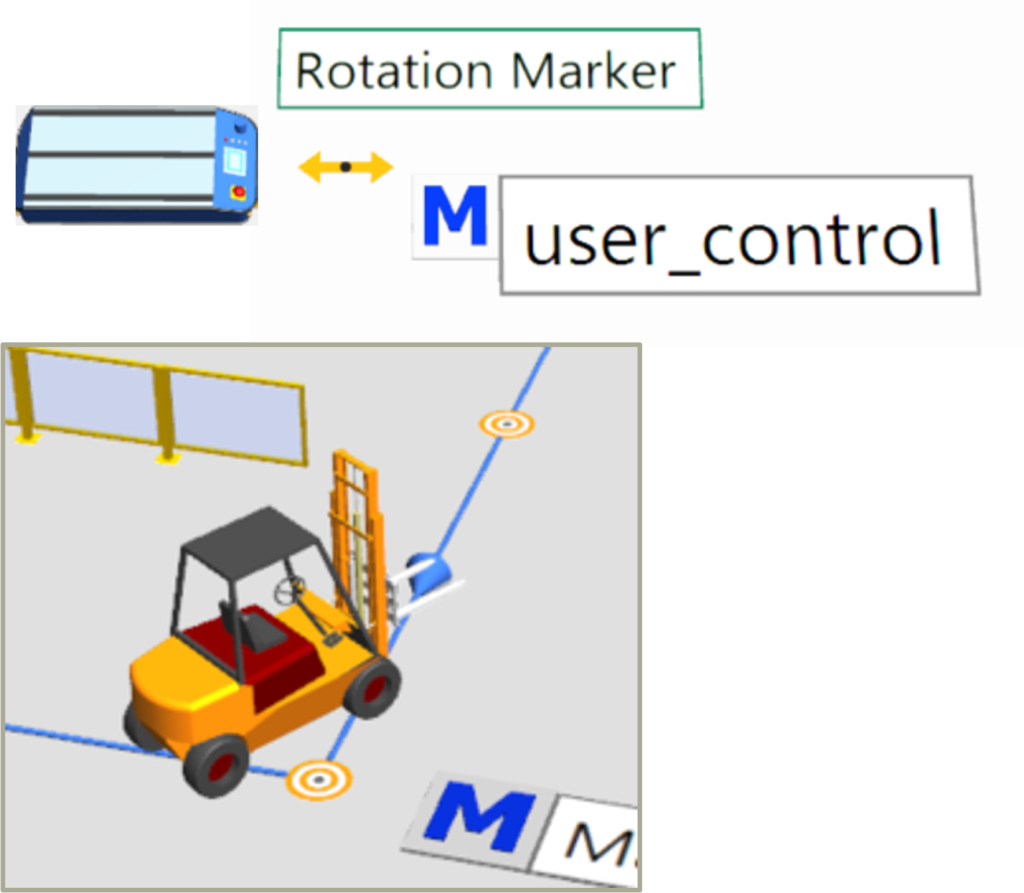

You also can now add your own action or user control to an AGV marker. This user control is automatically executed once an AGV reaches or passes the marker. This feature makes it very easy to implement customized activities like unloading an AGV or counting the AGVs that have already reached or passed a certain marker.

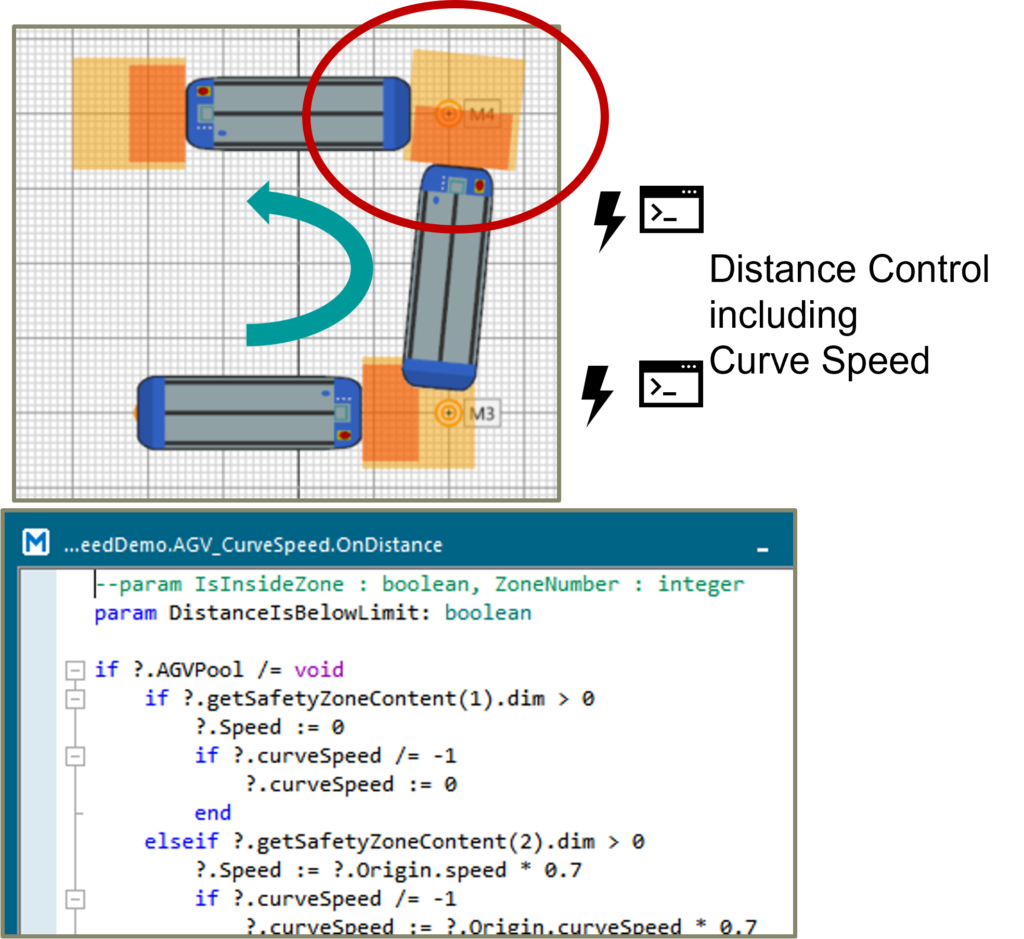

For a realistic driving behavior, we added the setting for a reduced curve speed. When defined, the AGV automatically slows down in a curve and goes back to normal speed after the curve. Together with the distance control, this feature helps to avoid AGV collisions in driving parkours.

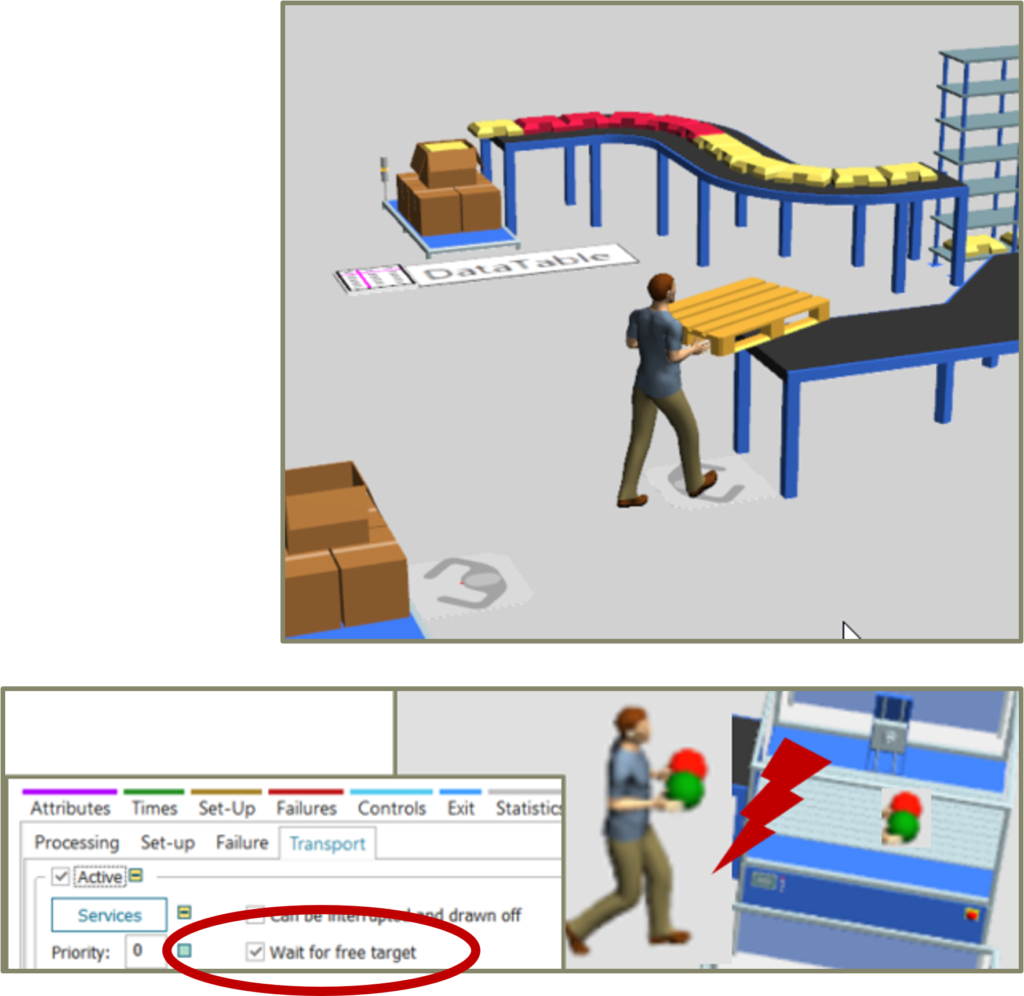

In version 2302, the carry-part feature of operators has been extended to additional objects. You can now use this functionality together with part sources and sinks and conveyor belts. A new strategy for requesting a carry-part service, “wait for free target”, prevents a worker being called to carry a part to a station that is still occupied.

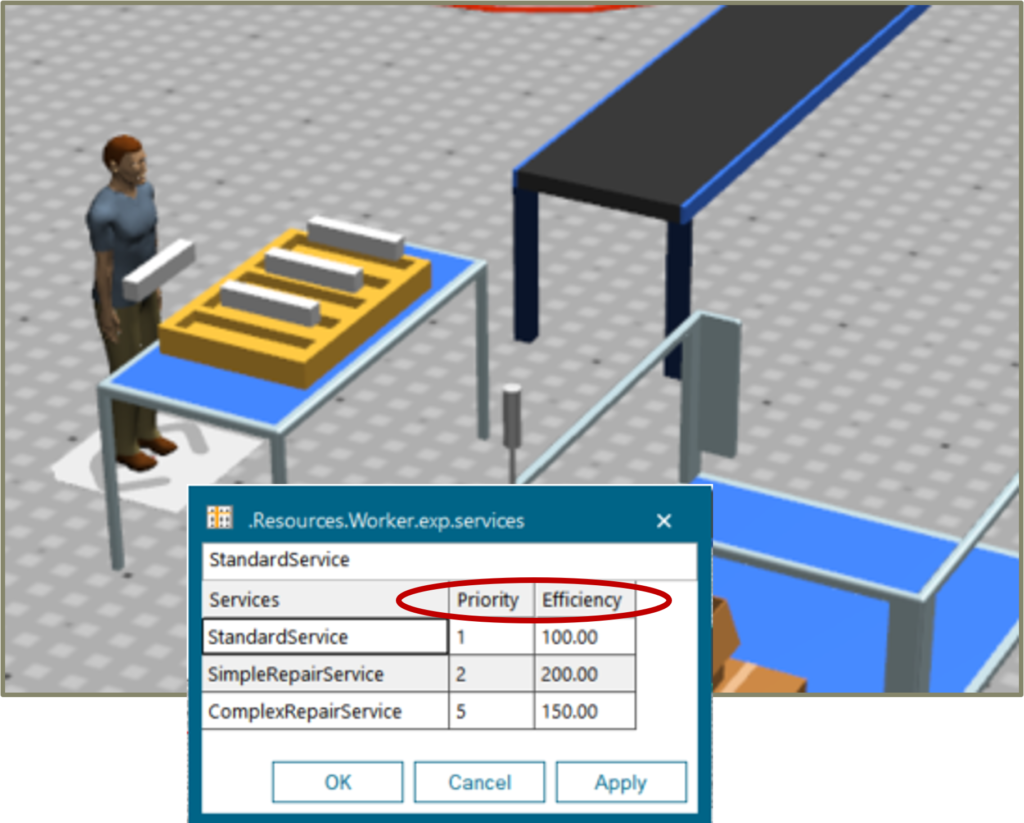

The automatic worker allocation to a job is based on priorities. In Plant Simulation 2302, we enhanced the priority definition. You now can define individual priorities for each service that an operator provides. In the same way, you now can define different efficiency settings for each individual operator’s services. This refinement reflects personal training levels and provides a nearly out-of-the-box functionality for learning curves, which are important in complex product assembly scenarios.

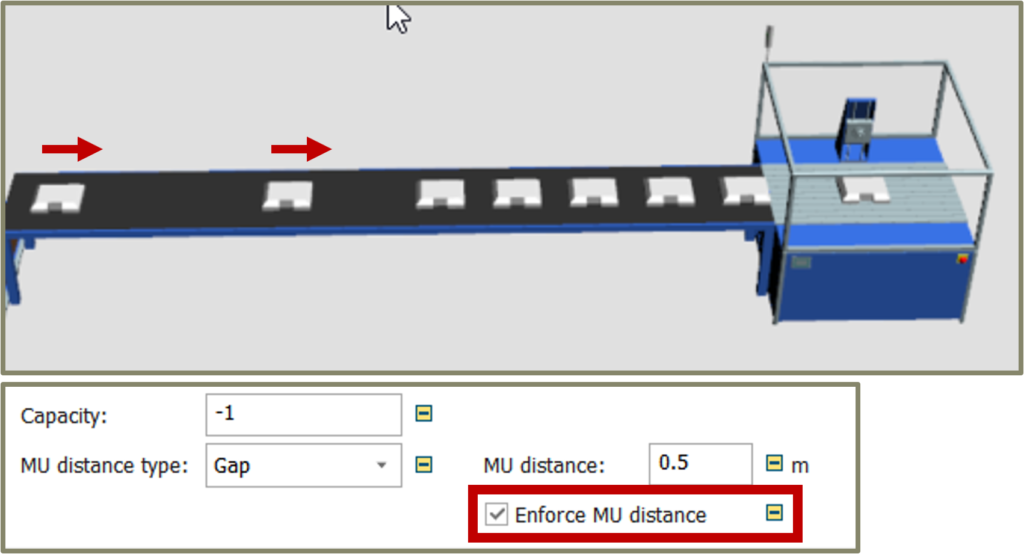

In many conveyor systems, it is possible to keep a gap between parts even in blocking or accumulation areas. You now can use this functionality as an out-of-the-box setting for Plant Simulation conveyor objects.

Visualization enhancements

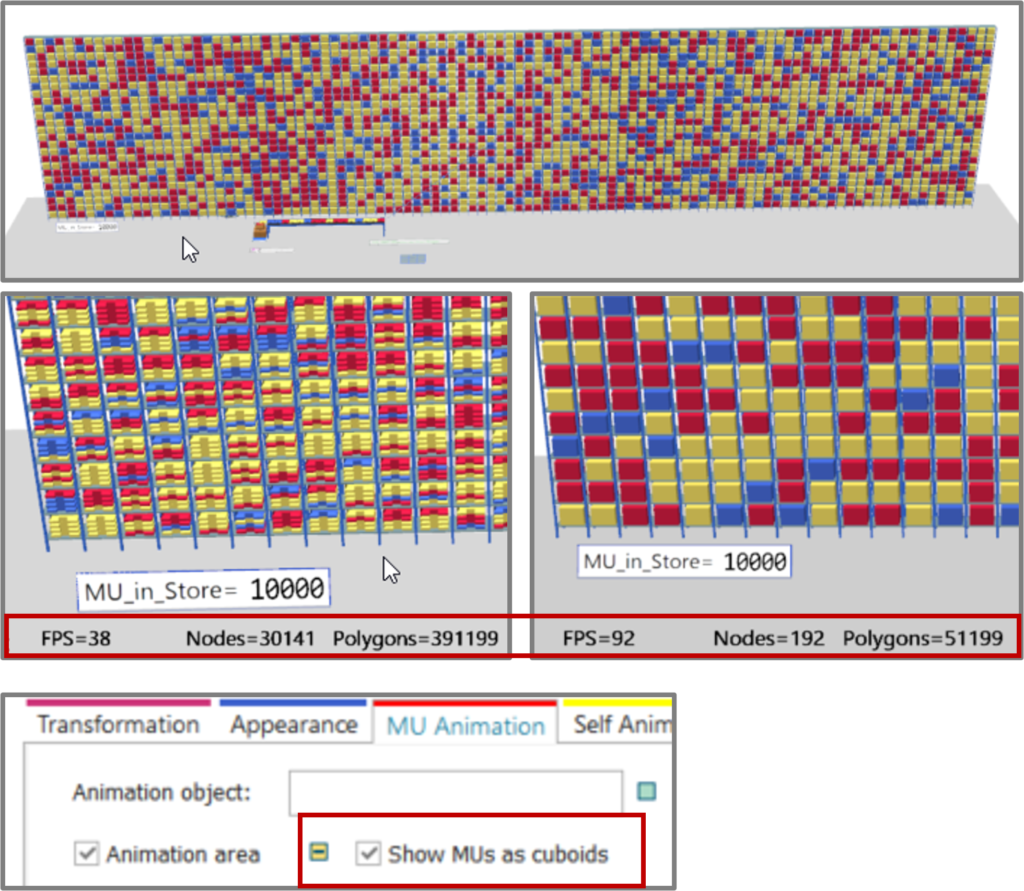

In Plant Simulation 2302, we added the highly efficient bounding box or cuboid representation for moveable parts residing in a store or buffer. With this option set you can achieve fluent simulation model visualization without hiding the parts. You can have both visual feedback of the fill degree in the rack of large stores or containers and a high, 3D rendering frame rate per second.

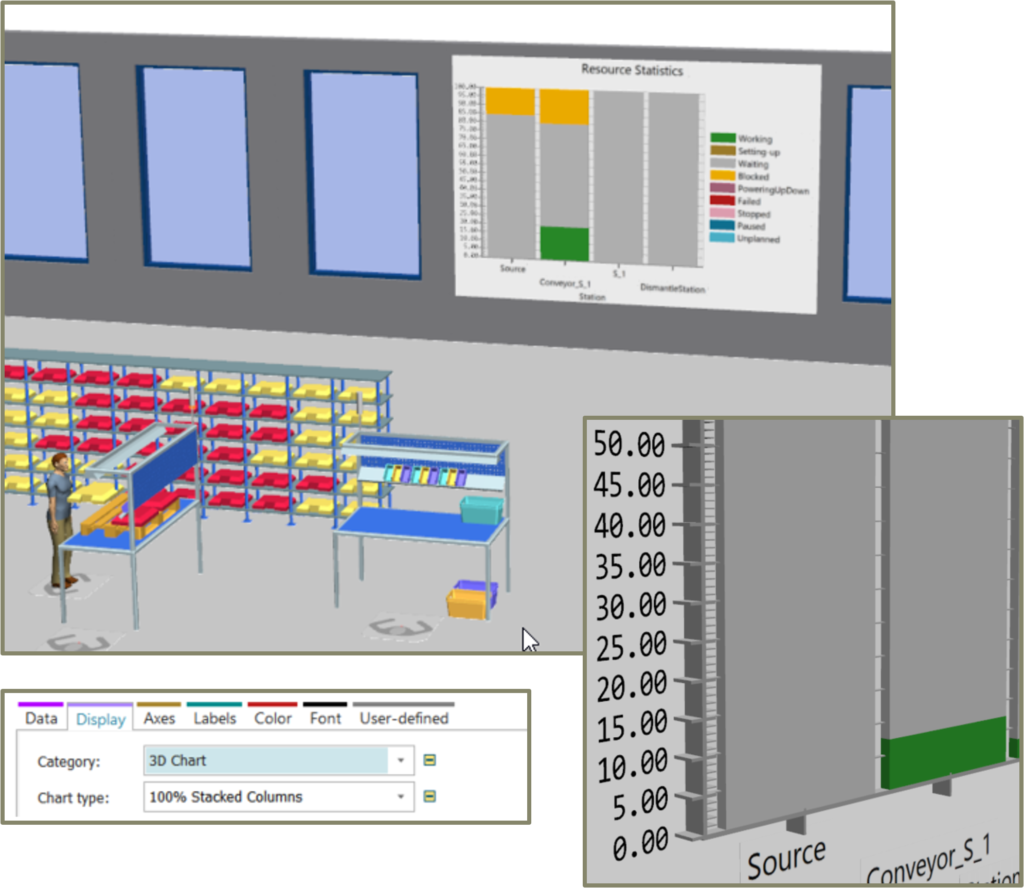

The new chart representation in 2302 uses real 3D graphics. This eliminates unwanted pixel effects when zooming into a simulation model, as seen in previous versions. You can arrange several charts and pin them to a dashboard area, for instance, at the end of a production line.

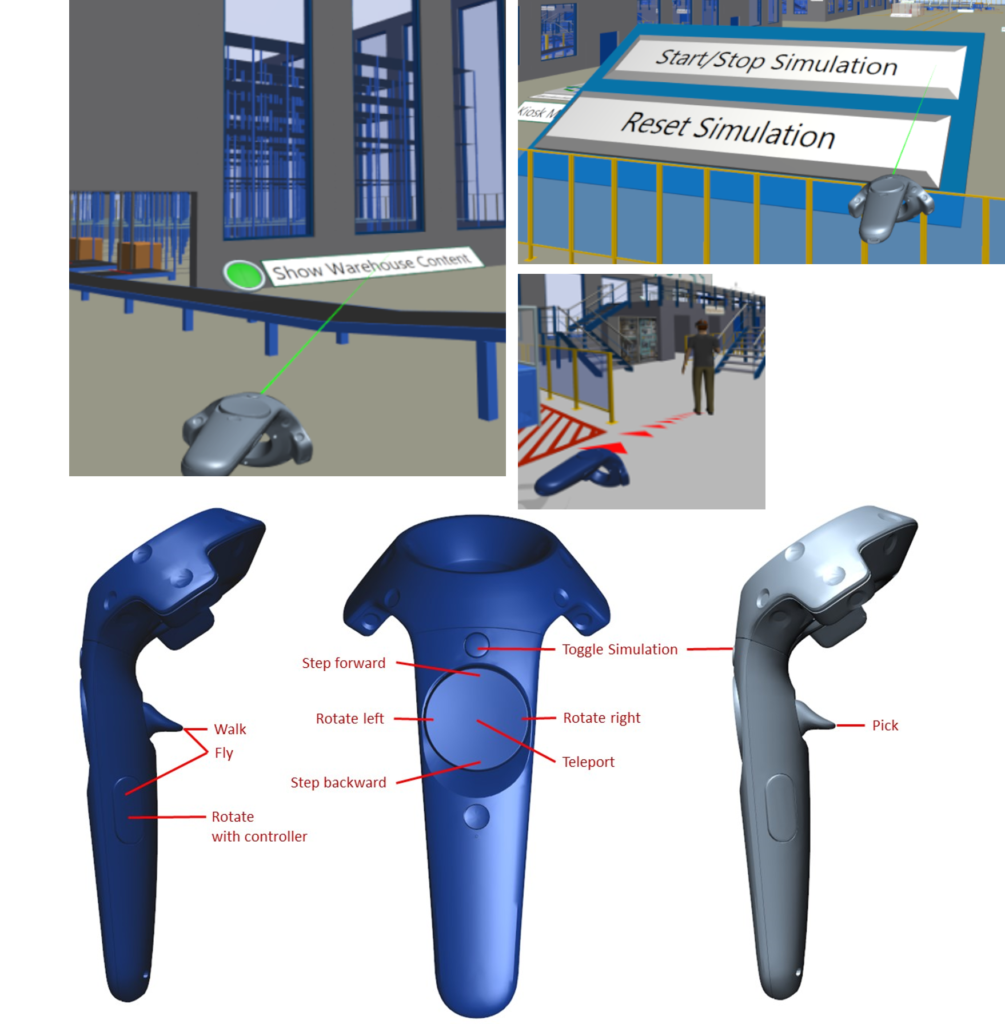

In this software release, you get several features for a better virtual reality (VR) experience with simulation models. Selecting the VR start position and controlling your movement in VR is much improved and you are now able to interact with the simulation model in VR. While immersed, you can start and stop the simulation, press buttons and select checkboxes. In this way, you can either execute predefined actions or you can modify simulation parameters and run different simulation scenarios directly in VR.

Virtual commissioning enhancements

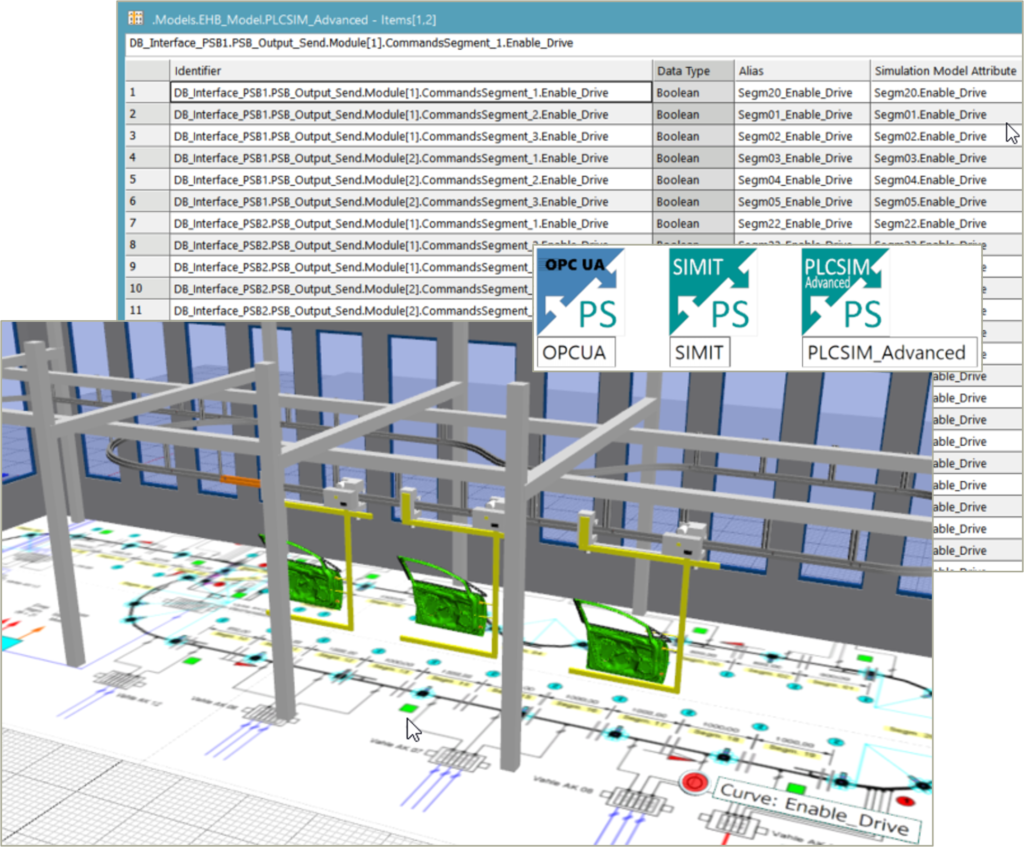

The reworked Open Platform Communications Unified Architecture (OPC UA) interface is now based on the same OPC UA solution that is commonly used in other Siemens AG groups. The new OPC UA supports security levels with settings for user account and password and the usage of encryption and certificates.

The datatype “string” has been added to the set of supported datatypes for the PLCSIM Advanced interface. The item update workflow with virtual commissioning interfaces is improved by highlighting new, changed and deleted signals and data items. This simplifies update workflows between automation control systems like PLCs and Plant Simulation by highlighting changed items where the simulation engineer most probably needs to adjust the Plant Simulation model.

Additional enhancements

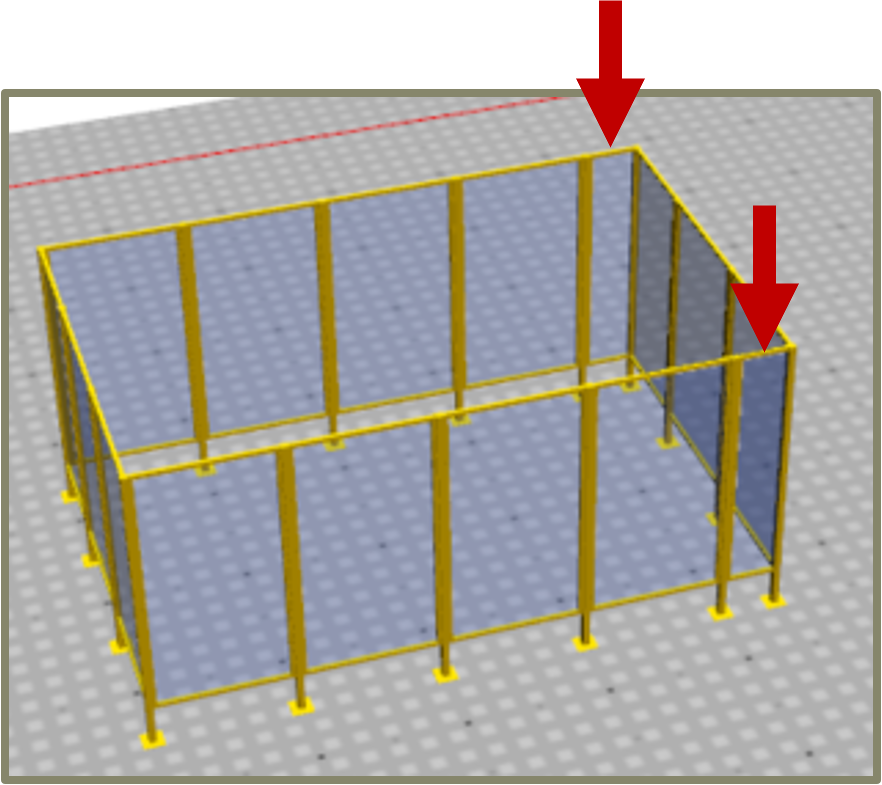

The layout of fence and factory wall segments is improved in Plant Simulation 2302, as you now can define the position of fill segments.

We also added a new statistic value for buffers for better detection of material flow blockages.

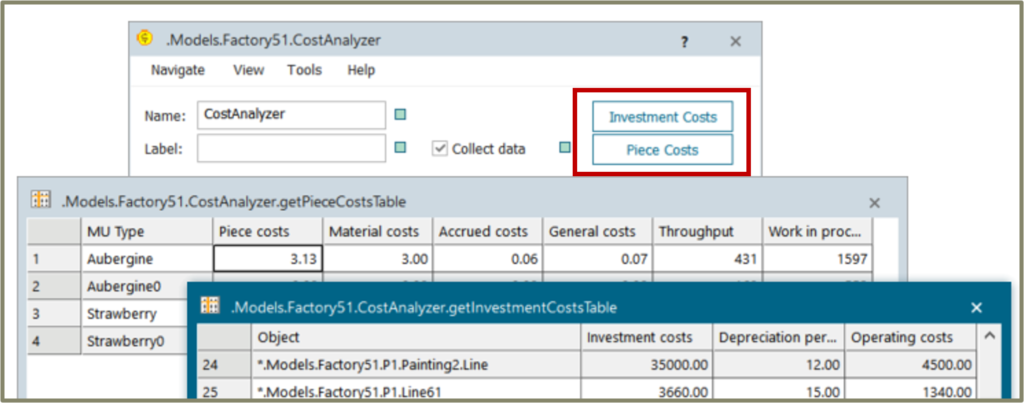

For the cost analyzer objects, it is now possible to access the results table directly out of the objects’ user dialog.

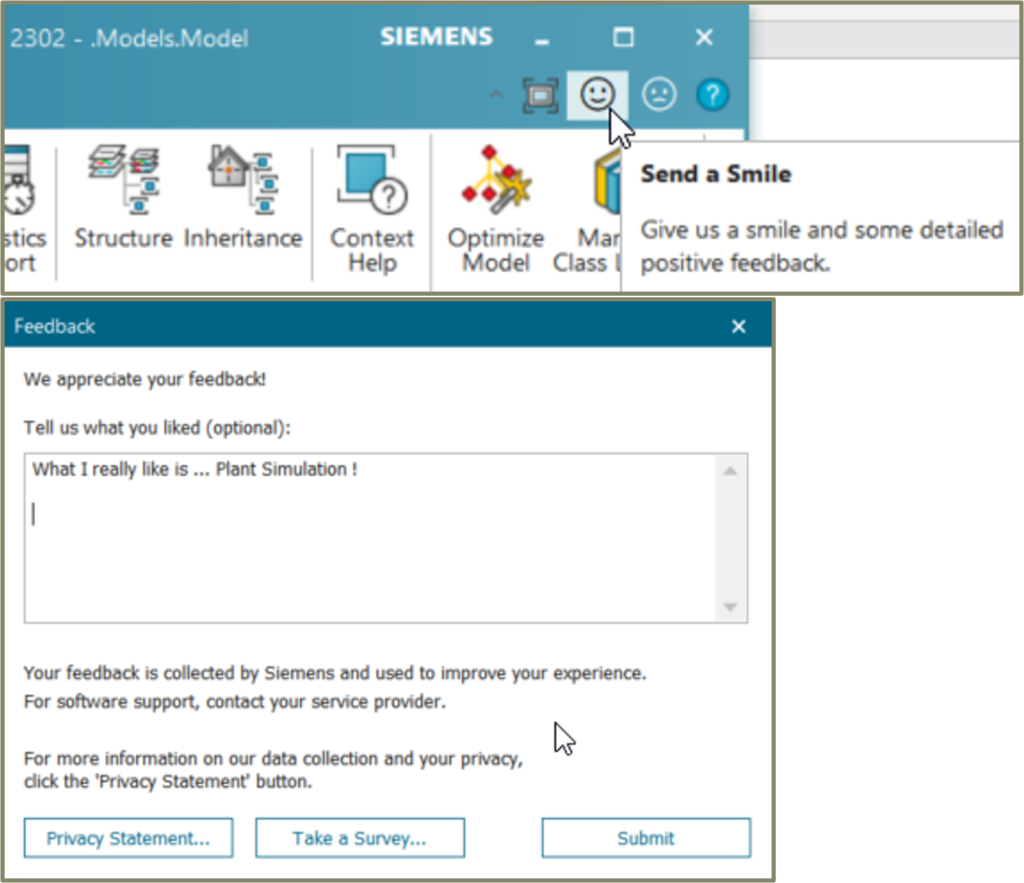

The “voice of the customer” feedback dialog has been added for an immediate and simple way of sending your feedback via “smile and frown” emojis (buttons) in the Plant Simulation default ribbon menu.

These are just some highlights of the many advancements delivered with the latest release. For complete details on the new features of Plant Simulation 2302, please refer to the release notes and online help offered with the software download.

You also can join us at Realize LIVE to hear more about the latest in Plant Simulation software from both Siemens employees and customers alike.

And don’t forget about the Plant Simulation Worldwide User Conference taking place in Munich, Germany this year.

And, as always, hop on over to the public community and website for all things Plant Simulation.

Yours in factory simulation,

(on behalf of the entire Plant Simulation product team)