The Battery Show 2023 – explore Siemens battery industry solutions

Join Siemens at booth 453.

The Battery Show North America takes place from September 12-14, 2023 at the Suburban Collection Showplace in Novi, Michigan, USA. Be our guest at The Battery Show and Electric & Hybrid Vehicle Technology Expo.

Accelerate your battery industry transformation

Discover the full potential of your battery production with our automation and digitalization solutions. From electrode production to battery cell, module and pack production all the way to the recycling of batteries, we can help you maximize your battery production end to end.

Our IoT compliant technologies and solution-based offerings are designed to help you reduce costs and increase efficiency. We guarantee compliance with the latest safety standards and can help you achieve a sustainable production process.

Learn how Siemens can help you transform your battery production.

Topics covered include:

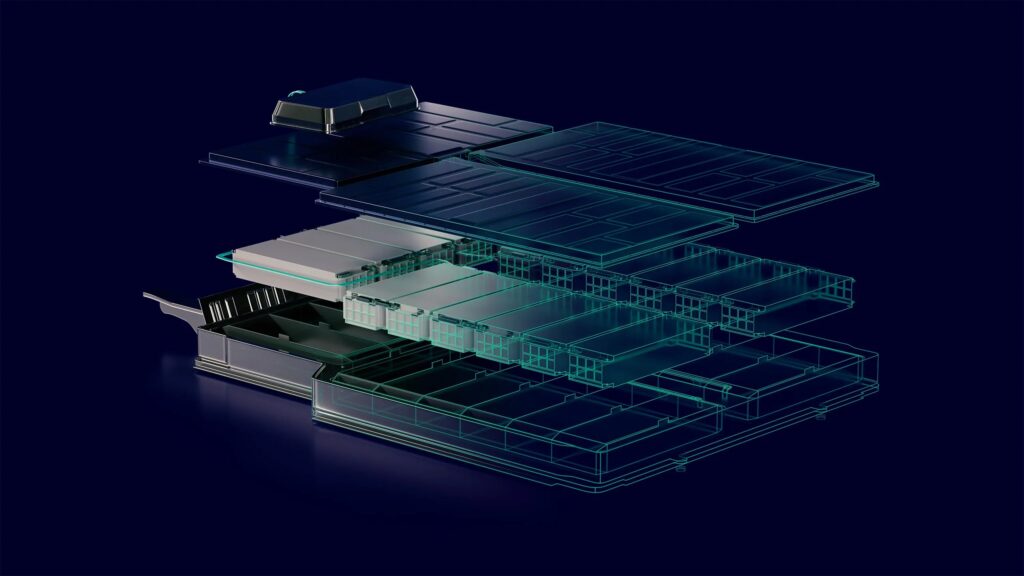

Accelerated battery development

Battery manufacturers need to account for chemistry, cell design, electrical, electronics, mechanical and software domains and their interdependencies while designing and engineering batteries. They must establish a more agile and collaborative way of working while building their organization and their factories at the same time. A comprehensive battery digital twin is needed to deliver an accurate virtual representation of the entire battery development process, including material innovation, cell and pack engineering, software development and system integration. Deploying the capabilities of the digital twin will allow you to account for the complex interdependencies between multiple domains and address all design and performance trade-offs up front, resulting in an accelerated battery development process and optimized design.

- Cross-domain, quality-driven collaboration – synchronize all engineering disciplines in a collaborative environment to ensure development continuity.

- Efficient model-based development – virtually evaluate many design variants to meet safety, performance and cost goals.

- Integrated, concurrent software design – accelerate the development and validation of defect-free and secured battery management systems.

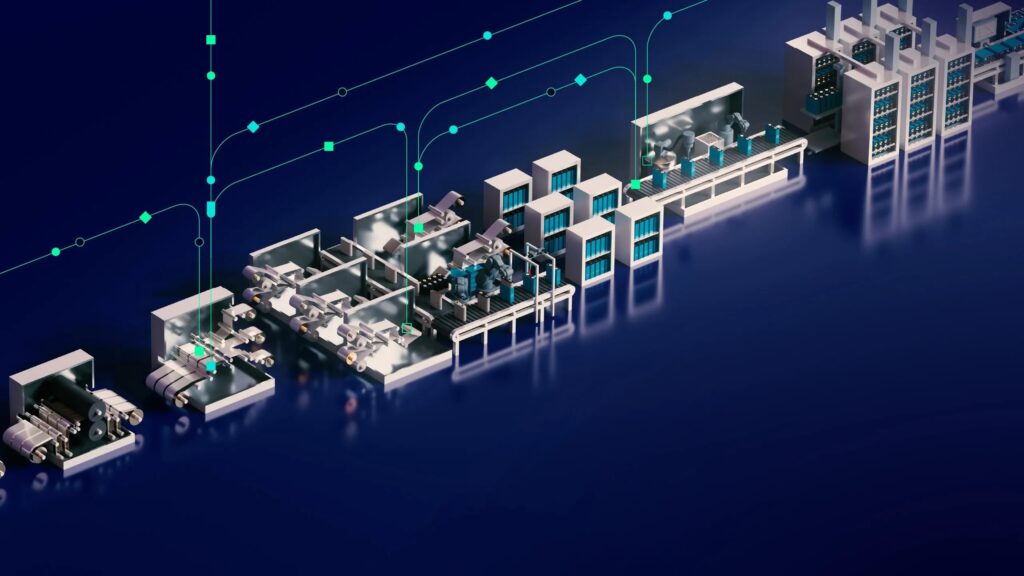

Battery smart manufacturing

Unprecedented growth in electric vehicle (EV) demand has propelled the battery market to new heights. As a result, global battery demand will surge exponentially, and manufacturers must figure out how to meet it. To support the increase, many battery startups, spin-offs and OEMs are building Gigafactories.

You need a way to develop battery production processes that can be executed flawlessly and scaled quickly without increasing scrap or jeopardizing quality. Your processes must be flexible enough to incorporate future cell innovations seamlessly.

- Virtual development of manufacturing – virtually design and validate manufacturing machines and processes before implementing them on the factory floor.

- End-to-end integration of your production – empower your digital twin with all product manufacturing information, standardization libraries and virtual models to establish an end-to-end integration of your production.

- Intelligent production excellence – increase line speed and throughput targets by leveraging a self-organizing ecosystem.

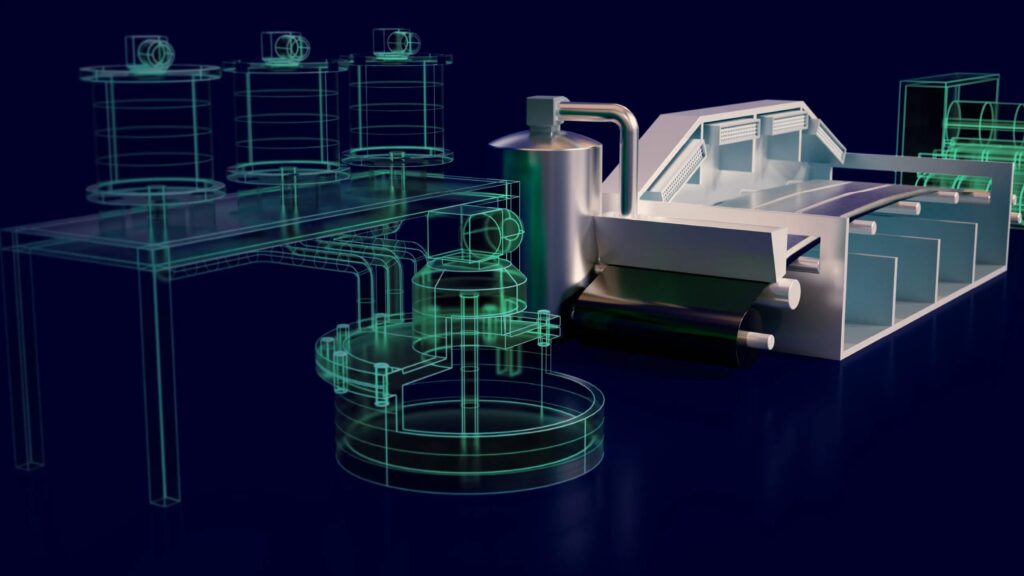

Advanced machine engineering

Many countries have a desire to be leaders in the growing battery industry through the building of high-output battery plants, with financial incentives to encourage local development. This is resulting in a shortage of machines required for the battery manufacturing process. To address this supply chain risk, automakers are building their own Gigafactories or entering joint ventures, further increasing demand for specialized manufacturing machinery.

Today’s market is strong for the machine builder, as demand outpaces supply with many orders being placed years in advance. Many incumbent machine builders are growing their operations by building new facilities closer to demand and simplifying supply chains. But there is also an opportunity for other machine builders with the right skills and experience to pivot into battery machinery, diversifying the supply chain.

- Standardization – adopt common equipment and interfaces to meet customer demands.

- Integrated concept to commission – faster delivery through multi-discipline collaboration and mechatronics.

- Grow service opportunity – gain operational visibility through integrated sensors and cloud-based monitoring.

We look forward to seeing you there.