Estun Automation reduces shopfloor commissioning time by 30%

Estun uses Siemens simulation and virtual commissioning technology to accelerate design, validate and deploy battery and photovoltaic production lines at a lower cost.

In the realm of intelligent manufacturing, the widespread adoption of digital twins and virtual debugging has become increasingly prominent. By proactively analyzing production line design, manufacturing processes, and the control logic and code governing the automation equipment in the digital realm, one can promptly implement timely adjustments and optimizations. This not only ensures precise onsite debugging but also expedites the product launch process.

By utilizing digitalization and simulation in the design and implementation of automation equipment, Estun Automation Co. reduced the onsite commissioning time of production lines by 30% and comprehensive commissioning costs by 20%, helping customers to reduce costs, shorten the production period and improve efficiency.

Optimize production line commissioning, cycle time, cost and quality at the same time

Founded in 1993, ESTUN AUTOMATION CO., LTD (Estun) is a pioneer in the field of motion control and industrial robotics, and complete solutions in China. With three decades of advanced robotics and innovation, Estun has become a recognized and respected international brand by adhering to the corporate mission of “Automation for All.” Estun operates in 64 countries and regions around the world, providing customers with immediate, convenient and complete business services.

While selling industrial robots and automation products, Estun also focuses on China’s advantageous industries such as lithium batteries, photovoltaic and new energy, specifically providing automated production lines for manufacturing companies in these fields. For example, Estun enables the production deployment of robots developed for the lithium battery industry, which are suitable for various types of large cylindrical and square battery cell module assembly lines. These robots enable higher efficiency during energy storage battery and power battery production, which is recognized and favored by several leading lithium battery enterprises in China.

The need for a customized manufacturing solution amid a complex battery market

Various manufacturers in the battery industry build unique and specialized products and types based on the distinct chemicals used within batteries, including lithium-ion, lithium iron phosphate and lead-acid. There are notable differences in the form of the product and the manufacturing process to produce these battery types, primarily due to variations in the chemicals utilized. Moreover, the differences in battery types extend beyond chemical composition and can vary due to the mechanical shape of the battery cells, modules and battery packs tailored for different customers. Therefore, customizing manufacturing equipment is essential to meet the unique requirements of each battery type, accounting for both chemical composition and diverse mechanical configurations.

As these battery variations illustrate the nuanced complexities between chemical composition and mechanical design, addressing these multifaceted distinctions becomes essential in the quest for customized manufacturing solutions. The rapid development of the new energy market is accelerating the pace of the customer’s product iteration cycle and the frequency is increasing. Therefore the high demand for battery-related products has surpassed the capabilities of traditional hardware equipment, which typically relies on onsite production line debugging. If manufacturers like Estun rely on traditional hardware equipment, the costs become too high and the production cycle is difficult to control, making it difficult to adapt to the competitive market demand.

To speed up the delivery of automation equipment for lithium battery and photovoltaic manufacturing, Estun must transform its traditional operations to shorten the cycle of production line development and debugging. Adopting digitalization will enable Estun to accelerate production and ensure quality. More importantly, it will help Estun quickly recoup capital, reduce the high cost of onsite production line development and debugging, and realize immediate control of the production process.

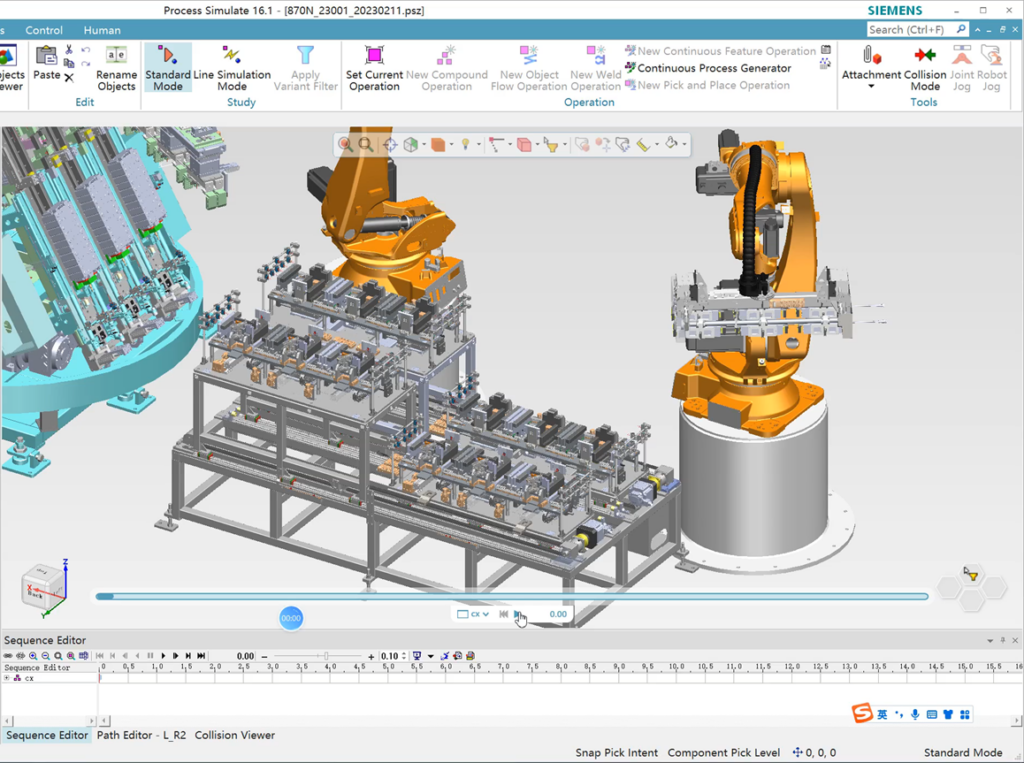

Tecnomatix Process Simulate is a must-have for virtual commissioning of production lines

Estun began using the virtual commissioning capabilities of Siemens industrial simulation software Process Simulate in the Tecnomatix® portfolio to drive the company’s R&D process transformation. After computer-aided design (CAD) design, engineers build digital twins in Process Simulate for production equipment and manufacturing processes, including cell and module conveyors and fixtures, and robots working with turntables to pick and place parts. The digital twin realizes the visualization of the whole process and, at the same time, helps the engineers to automatically check for mechanical interferences and prevent multiple problems during the physical deployment process.

Production engineers can also use the cyclic event simulation feature in Tecnomatix Process Simulate to build the logic of a production process and then implement that logic through a Siemens PLC program. All robot trajectories, PLC control logic and code are verified and issues are virtually commissioned before the equipment is installed on the shop floor. This creates a major time savings and effort for Estun to execute onsite commissioning of automated production lines for its customers.

This solution is used in a digital environment for the design, validation and optimization of complete mechanical, robotic and automation systems for automated production lines in lithium battery and photovoltaic manufacturing, allowing line commissioning with maximum independence from hardware equipment, resulting in virtually zero burden on corporate inventory and a significant improvement in the efficient use of corporate capital without the risk of damaging expensive hardware assets.

Tecnomatix Process Simulate supports offline programming (OLP) of more than 30 brands of industrial robots around the world, including “The Big Four” – ABB, Fanuc, KUKA and Yaskawa. Tecnomatix Process Simulate helps manufacturers like Estun to integrate its robots into the production process in a short period of time.

A collective development: offline programming technology also reduces production line debugging time and cost

The collaboration between Estun and Siemens is comprehensive, not only using Tecnomatix Process Simulate for virtual debugging, but also including the joint development of offline programming packages for industrial robots, which integrates the Estun robot models (3D model libraries, OLP, etc.) with Process Simulate software. This integration accurately simulates the robot’s motion sequences and automatically generates the robot control code that can be downloaded to the robot’s physical controller to control the hardware devices, providing a more efficient and effective user experience for Estun’s customers.

With Tecnomatix Process Simulate software platform, combined with the knowledge of ESTUN robot virtual controllers, process principles, model libraries, etc. in the new energy, automotive and other intelligent manufacturing industries for the customer’s new production lines, old line renovation, equipment maintenance and other scenarios, we can now use a digital twin solution to reduce the delivery cycle while improving the product quality.”

Chang Xiaolei, General Manager, Digital Business, Estun Automation

Through offline programming technology, the robot can reduce the interference to the production line, realize the efficient and flexible work of the production line, and reduce the risk of malfunction and loss. Parallelly, through the subsequent Internet of Things (IoT) technology, data collection and analysis can be achieved, providing data support for the optimization and upgrading of the production line.

Alexander Greenberg, Director of Advanced Robotics Simulation at Siemens Digital Industries Software, explains that since the beginning of 2023, Siemens has been working closely with Estun to develop an offline programming package for their industrial robots. Siemens collaboration with Estun empowers intelligent manufacturing by transforming the production line planning and debugging process.

By leveraging the power of 3D simulation and virtual commissioning, combined with the offline programming package, we continuously develop and improve. Estun has achieved remarkable results, including a 30% reduction in commissioning time and a 20% decrease in overall costs. As we continue to work closely with Estun, we are confident that our partnership will drive further innovation and deliver even more advanced automation solutions that meet the evolving needs of our customers in the rapidly evolving market.”

Alex Greenberg, Director of Advanced Robotics Simulation, Siemens Digital Industries Software

In the process of digitalization, Estun will also continue to work with Siemens Digital Industries Software to provide momentum and inject positive energy into intelligent manufacturing to improve quality, increase efficiency and reduce costs.

![Automation World features Tecnomatix Process Simulate: the essential software for virtual commissioning [ARTICLE]](https://blogs.stage.sw.siemens.com/wp-content/uploads/sites/7/2024/03/automation-world-process-simulate-2-395x222.png)