Process Simulate Human in Aerospace and Defense Manufacturing [WEBINAR]

Improving efficiency and safety with human simulation software

The aerospace and defense industry stands at the forefront of technological innovation, continually pushing the boundaries of what is possible in air and space exploration, national security, and defense systems. Manufacturing processes in the aerospace and defense industry are complex due to stringent regulations enforced as well as the integration of advanced technologies, tight tolerance requirements, and customization needs further adds to this complexity. For example, think of stringent regulatory requirements for the A&D space which demand precise adherence to safety and quality standards throughout the assembly process. The incorporation of cutting-edge technologies, such as advanced materials and complex electronics, requires specialized knowledge and equipment to ensure proper integration and functionality. Despite these challenges, effectively navigating them is essential for maintaining the reliability, performance, and safety.

In today’s webinar, we focus specifically on how human simulation technologies and virtual reality are increasingly being deployed to optimize processes, enhance training, and improve manufacturing workflows. By creating a digital twin of human workers within simulations, manufacturers can assess ergonomic factors, identify potential hazards, and streamline workflows to prioritize worker well-being while driving operational excellence. Improving manufacturing efficiency and safety is paramount, which is where A&D manufacturers can realize powerful manufacturing outcomes using Siemens Tecnomatix Process Simulate Human.

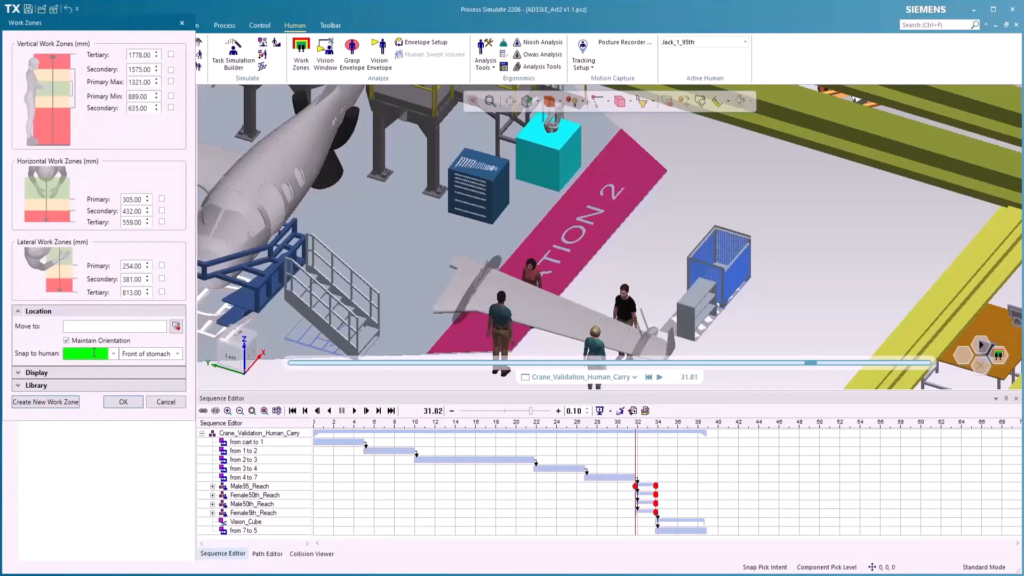

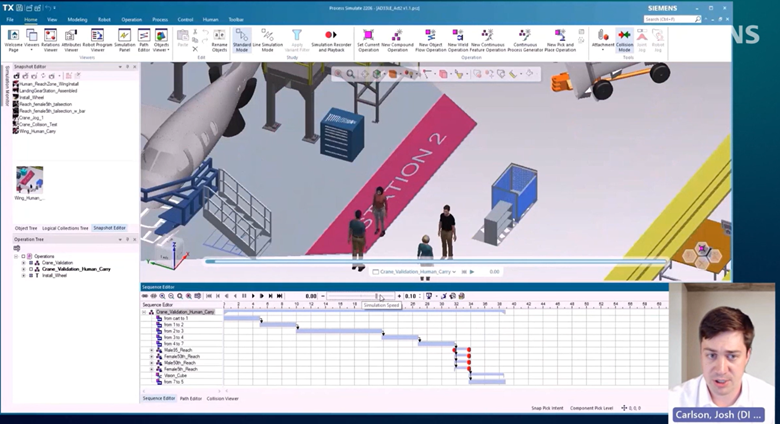

In this Aerospace and Defense webinar series, Josh Carlson, Siemens technical product manager for robotics and automation, demonstrates several use cases of Process Simulate Human software for A&D manufacturing. Dive into the key benefits of human simulation technology within the industry. Josh emphasizes two key industry trends: sustainability extending beyond environmental impact to encompass human ergonomics and worker safety, along with addressing workforce challenges concerning knowledge transfer and skills gap.

Application of human simulation in assembly processes

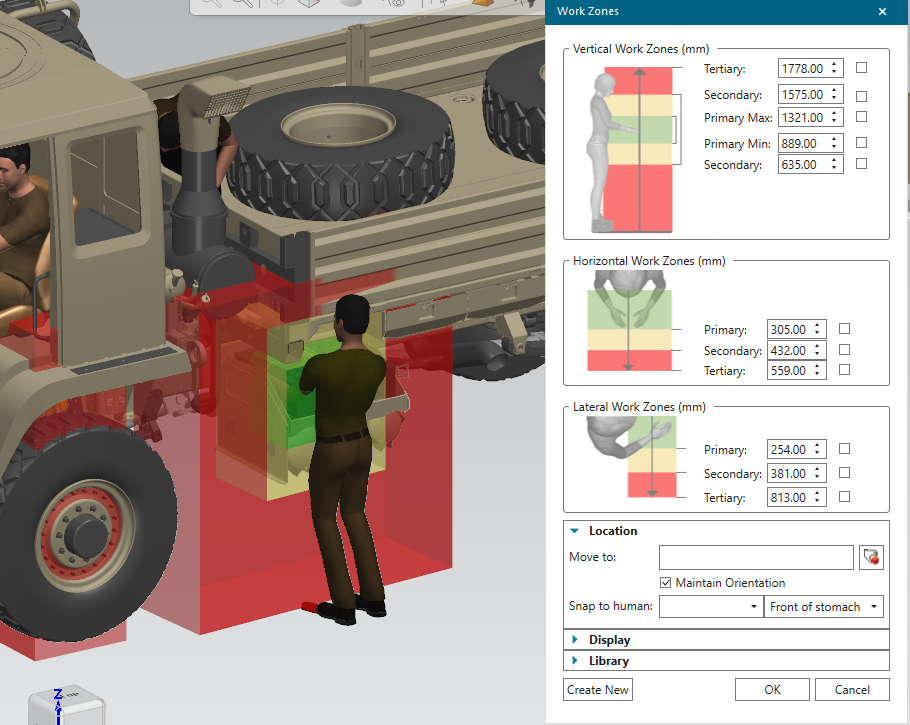

The demonstration illustrates how Process Simulate Human optimizes assembly processes like wing assembly and wheel installation on landing gear. It assesses station layout feasibility, collision avoidance, and ergonomic suitability for technicians. Additionally, it enables comparisons between workers of different sizes, aiding in process and workspace optimization.

Evaluation of product design for usability

Human simulation is utilized in evaluating product design for usability during the product lifecycle. For example, during wing assembly, ensuring workers can handle heavy components safely involves evaluating gantry height, fixture placement, and worker ergonomics. Prioritizing human health in production planning reduces workplace injuries and fosters a sustainable manufacturing environment. The webinar concludes with a glimpse into the next topic on robotics and automation simulation, highlighting the integration of virtual reality technology with simulation for enhanced collaboration and feedback. The significance of human simulation in improving efficiency, safety, and user satisfaction across aerospace and defense manufacturing processes is underscored.

As sustainability and workforce challenges shape the industry, considering human factors in manufacturing is crucial. Human simulation software enhances efficiency, safety, and innovation. Embracing this technology addresses evolving industry needs. Watch the webinar to learn about specific use cases of assembly for the A&D industry using Process Simulate Human.

If you missed the introductory webinar, you can find it here.