Empowering sustainability: Decarbonization strategies in construction process management with the integration and benefits of Plant Simulation

Paving the way for sustainable manufacturing

The case study of decarbonization strategies in construction process management by Isabella Deininger will be presented at the 2024 Plant Simulation User Conference, set to take place on Thursday, June 6th, 2024, at the Infinity Hotel in Munich, Germany. Attendees can expect a detailed exploration of the strategic utilization of digital models to drive decarbonization efforts within industrial environments. Isabella’s presentation offers insights and practical solutions for optimizing production processes and minimizing environmental impact.

Isabella Deininger is research associate and doctoral candidate at the Technical University of Munich. She has been at the forefront of exploring innovative solutions for decarbonizing production sites. Her experience in various industry roles has provided her with insights into the challenges and opportunities present in today’s manufacturing landscape. In this case study, she will examine the role played by digital models in advancing decarbonization strategies, highlighting their potential to drive sustainable practices in industrial settings.

by Falkenstein Projektmanagement GmbH

Challenge: Decarbonization strategies in construction process management

Industrial CO2 emissions pose a significant environmental challenge, necessitating urgent action to mitigate their impact. Traditional approaches to production often result in high carbon footprints, requiring a paradigm shift towards more sustainable practices, particularly decarbonization strategies in construction management. However, implementing such changes can be complex, requiring a comprehensive understanding of the production process and its environmental implications.

Solution

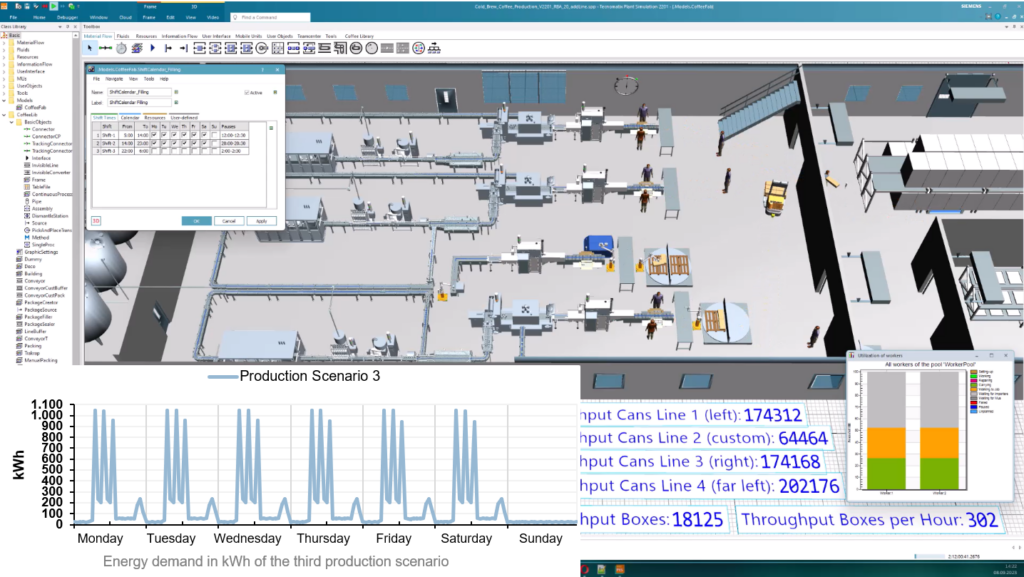

The research focuses on harnessing the power of digital models to streamline decarbonization efforts. By integrating building, production and energy models, she aims to create a cohesive framework that enables a holistic approach to sustainability. The case study demonstrates how digital technology can be leveraged to optimize production processes, minimize energy consumption and reduce carbon emissions.

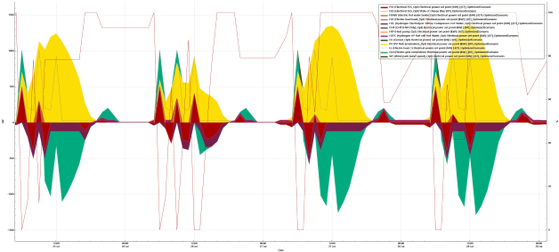

Chart of the CO2 emissions of various production scenarios.

What are the outcomes of the simulation?

In this instance, various options were explored across different production scenarios. Upon analyzing the results, the simulation yielded clear evaluations for each production scenario. For instance, it provided precise calculations of carbon dioxide emissions per year, presenting them as easily comparable figures.

Decicions based on calculated numbers

For example, in option 7, the initial production scenario 1 resulted in an output of 513 tons of carbon dioxide per year. However, in production scenarios 2 and 3, this amount could be reduced to 433 and 423 tons of carbon dioxide per year, respectively by making adjustments in the production simulation with Tecnomatix Plant Simulation. Following a comprehensive understanding of the factors influencing annual carbon dioxide emissions, production scenario 4 was developed. Remarkably, this scenario produced only 251 tons of carbon dioxide per year, representing a reduction of 49% compared to the original scenario, with a few trade-offs.

This simulation enabled the presentation of various production scenarios with possible options for it’s energy source mix for the management of the manufacturing that could potentially halve the annual carbon dioxide output.”

Isabella Deininger, research assistant, Technical University of Munich

Implementation

Central to Central to Isabella’s and her team’s approach is the use of advanced digital tools such as the architectural model from Falkenstein Projektmanagement GmbH and the production model based on Plant Simulation by Siemens. These models enable detailed analysis of the production site, allowing for the identification of areas for improvement and optimization. By simulating various scenarios, Isabella and her team can evaluate the effectiveness of different decarbonization strategies and refine their approach accordingly.

Important to mention, without the collaboration of an interdisciplinary team, consisting of the core team Andreas Trautmann, Dr. Bernd Koch, Christoph Falk, Mathias Langhans and Ralph Bauknecht, known for his simulation expertise, as well as the other extremely competent team members Andy Manley, Christian Falkenstein, Christoph Neher, Prof. Konrad Nübel, Dr. Martin Kautz, Nicolas Albornoz and Ralph Brecht (listed alphabetically), such a large-scale investigation would not have been possible!

Benefits

Decarbonization strategies in construction management offer a multitude of benefits for achieving sustainable industrial practices. Firstly, they contribute significantly to reducing carbon emissions, thereby mitigating the environmental impact of industrial activities. By adopting these strategies, companies can improve their environmental performance and meet regulatory requirements, enhancing their reputation and competitiveness in the market. Moreover, decarbonization initiatives often lead to cost savings by way of increased energy efficiency and reduced resource consumption. These savings can be reinvested into further sustainability efforts or allocated to other areas of the business, driving overall financial sustainability.

Additionally, implementing decarbonization strategies fosters innovation and technological advancement within the construction industry, spurring the development of cleaner and more efficient technologies. Furthermore, these strategies promote long-term resilience by future-proofing operations against potential regulatory changes and resource constraints. Overall, decarbonization strategies in construction management not only benefit the environment but also create opportunities for economic growth, innovation and competitive advantage in the global marketplace.

Results

Using digital models, significant reductions in carbon emissions can be achieved. Optimizing energy usage, streamlining production processes and implementing sustainable construction practices lower the site’s environmental impact. These results not only demonstrate the efficiency of digital technologies in decarbonization but also lay the foundation for future innovations in sustainable manufacturing. More detailed outcomes of the case study can be found in the publication on Springer Link. These results not only demonstrate the efficiency of digital technologies in decarbonization but also lay the foundation for future innovations in sustainable manufacturing.

Conclusion

This case study underscores the transformative potential of digital models in driving decarbonization efforts. By leveraging advanced technology and adopting a holistic approach, Isabella has successfully demonstrated the feasibility of sustainable production practices. The potential of decarbonization strategies in construction management for sustainable industrial practices is available today. As industries worldwide grapple with the challenge of reducing their carbon footprint, this research offers insights and solutions for creating a more environmentally responsible future.