Discover what’s new in Tecnomatix 2402 (February 2024)

Digitalization for advanced manufacturing.

The Tecnomatix® portfolio delivers advanced digital manufacturing software to empower businesses across diverse industries and sizes. Tecnomatix 2402 launched recently with several exciting new advancements in the areas of Teamcenter connectivity, UI updates, collaboration, robotics simulation, offline programming, virtual commissioning, human simulation and virtual reality.

In this blog, we explore how the Siemens Xcelerator portfolio, including Tecnomatix digital manufacturing software, helps companies minimize manufacturing risks and improve their production operations. Siemens Xcelerator is an open digital business platform that enables customers to accelerate their digital transformation easier, faster and at scale.

Tecnomatix software helps companies minimize manufacturing risks and improve their production operations. We are thrilled to bring these latest enhancements to you!

You don’t have Tecnomatix software?

General enhancements

The following new capabilities were released in 2402.

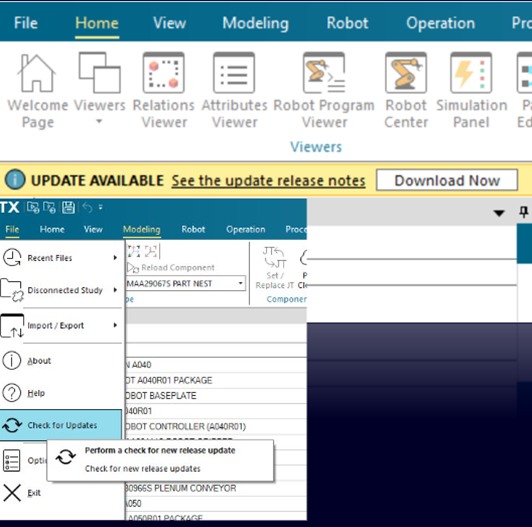

Frequent release updates

Tecnomatix 2402 introduces frequent release updates, replacing the traditional hotfix mechanism in favor of a more dynamic and responsive approach to software improvements. Now you can achieve seamless release updates through Process Simulate. Unlike the conventional hotfixes, these updates encompass both issue fixes and minor enhancements. This enhancement component takes center stage in alerting you about available updates upon launching Process Simulate. You can download and install updates directly within Process Simulate, providing a hassle-free and streamlined process.

For those who prefer a more controlled approach to updates, Tecnomatix Doctor allows you to disable update notifications in the release update setting dialog, accessible using the tools menu. Tecnomatix 2402 also introduces an active approach to staying current with the software. The new ‘Check for Update’ command, conveniently located under the File menu in Process Simulate, allows you to proactively search for software updates. This allows you to leverage the latest advancements whether you prefer immediate integration of updates or a more personalized approach.

Dark theme

Tecnomatix 2402 introduces a new dark theme in Process Simulate, transforming the visual experience. This feature impacts key UI elements like the ribbon, viewers and dialogs, excluding the graphic viewer for optimal clarity. The dark theme helps to emit less blue light, reducing eye strain and boosting work efficiency, especially in low-light conditions. You gain customization control with a theme setting, allowing seamless changing between the default light and the new dark theme. To better support the user of the dark theme, many icons in the dialog boxes were redesigned in vector (.svg) format to enhance the visualization across themes.

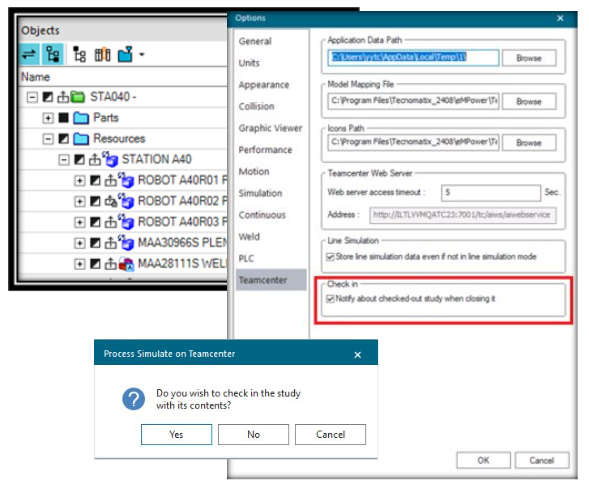

Process Simulate on Teamcenter

Authoring enhancements

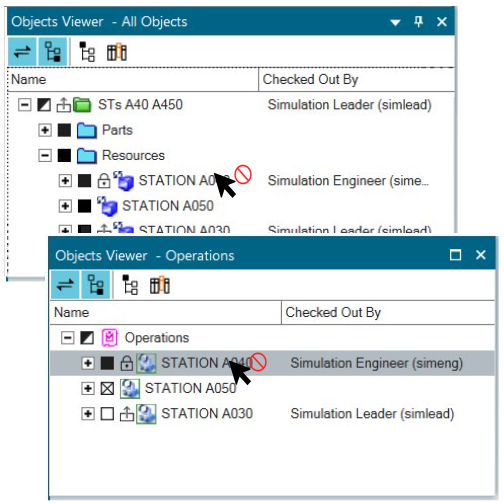

Explore new integration enhancements for Process Simulate on Teamcenter, starting with authoring improvements. To further ease authoring in Process Simulate on Teamcenter, Tecnomatix 2402 introduces visual cues in both the object viewer and the operation tree. These indicators, represented by dedicated icons on the object line, seamlessly communicate the access state of the object, adding clarity to the authoring process on Teamcenter. The three distinct icons to improve locking indication now appear in the status bar, including locked, checkout by the current user, and checkout by another user. When no access state icon is displayed, it indicates that the object is available for authoring.

You also can check-in the study upon exiting which improves workflow transparency and flexibility. This behavior can be customized through the Teamcenter tab in the options dialog. Receive notifications when closing a study that is checked out by a user, providing an immediate option to check-in the study with its content. These notifications not only refine the authoring experience but empower you with nuanced control over study content, ensuring a more intuitive workflow within Process Simulate on Teamcenter.

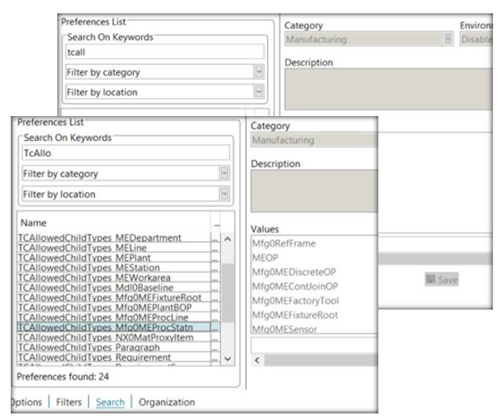

Validate permitted object types

In Tecnomatix 2402, enter a new era of precision and control with a rule-compliant modeling experience in Teamcenter connected and standalone modes within Process Simulate. Define permitted object types for descendants or assignments per object type. The resource tree and operation tree now carefully adhere to these rules, allowing only objects of specified types to be added below the selection.

This meticulous control enhances the modeling process, preventing errors and ensuring a streamlined structure. Specifically, processes and operations are now governed by these rules, allowing only assignments of resources, parts and MFGs of designated types. This feature extends its influence on any command or action that modifies the resource structure in the resource tree and the process structure in the operation tree

Improved authoring policy

Process Simulate on Teamcenter also introduces a crucial enhancement with two beta features in Tecnomatix Doctor. The ‘validate write access’ option ensures users can only modify objects they have write access to, enhancing data reliability and collaborative workflows. The ‘enforce object checkout’ option restricts users to modifying only checked-out objects, promoting controlled multi-user collaboration.

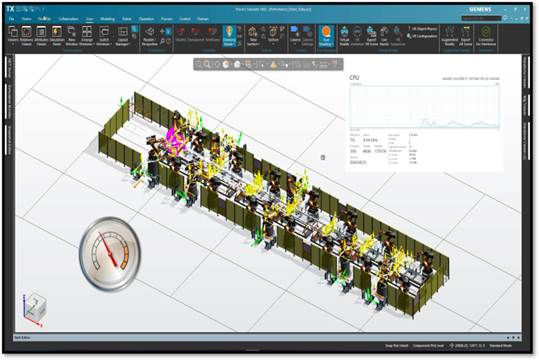

Graphics performance

We understand the importance of responsive and efficient performance in your daily engineering tasks, which is why Tecnomatix 2402 delivers an elevated experience by prioritizing graphics performance enhancements. Aimed at tackling common bottlenecks, the new performance capabilities ensure swift access to Process Simulate studies and streamline critical operations, including blanking, object selection, duplication and deletion.

Notably, it introduces heightened responsiveness in undo and redo commands while improving display speeds for efficient study exploration. The ability to organize and display objects by type enhances project management, while optimized functions like snapshot creation and improved performance in complex operations contribute to a seamless engineering workflow.

Automatic size culling

In scenarios where massive datasets surpass 40,000 shapes, the ‘size culling’ algorithm is now automatically triggered to optimize performance while culling smaller objects that may not be immediately visible. This algorithm dynamically hides objects in the graphic viewer based on their size relative to the entire study and the user’s perspective.

Easily minimize the number of objects requiring refreshing in the graphic viewer. This reduction in workload translates to faster response times, significantly enhancing the overall efficiency of the user experience. Notably, the algorithm adapts to changes in visibility or the introduction of new objects, ensuring automatic adjustments for optimal performance.

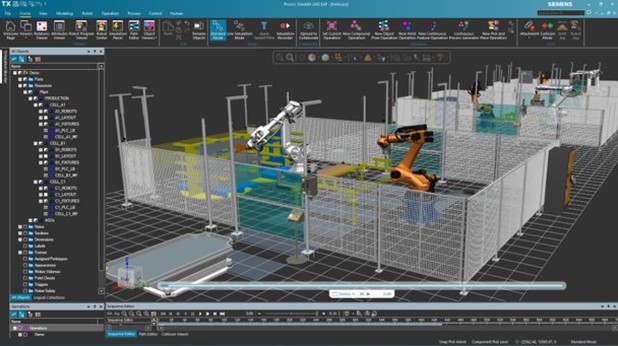

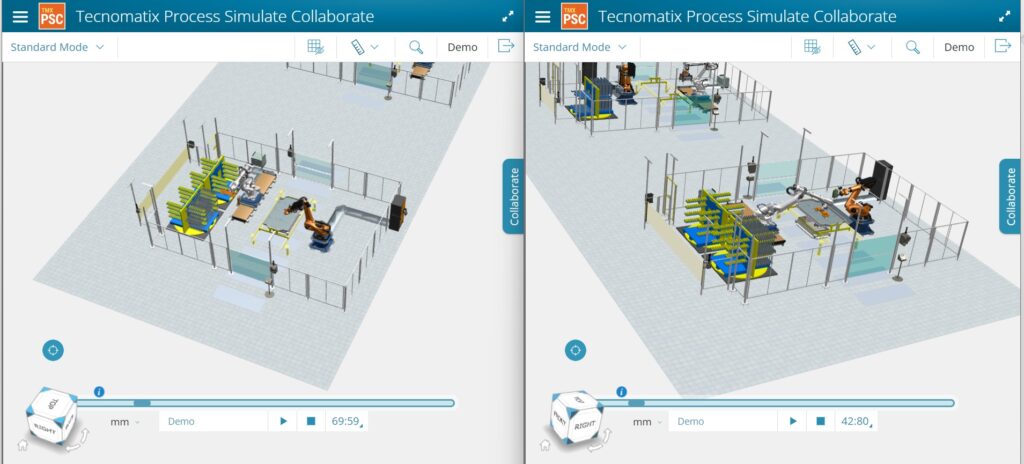

Process Simulate Collaborate

Tecnomatix Process Simulate Collaborate, is a cloud-based, 3D collaboration platform to visualize, review and analyze Process Simulate studies in a collaborative environment. The 3D simulation collaboration tool helps save time and effort by extending Process Simulate studies into the cloud providing internal and external stakeholders access to the richness of your Process Simulate studies, saving time and effort. Collaboration is much improved via dynamic 3D visualization, simulation and electronic feedback.

Process Simulate Collaborate is a Siemens software as a service (SaaS) application that was released early in 2023 and recently was updated with exciting new features.

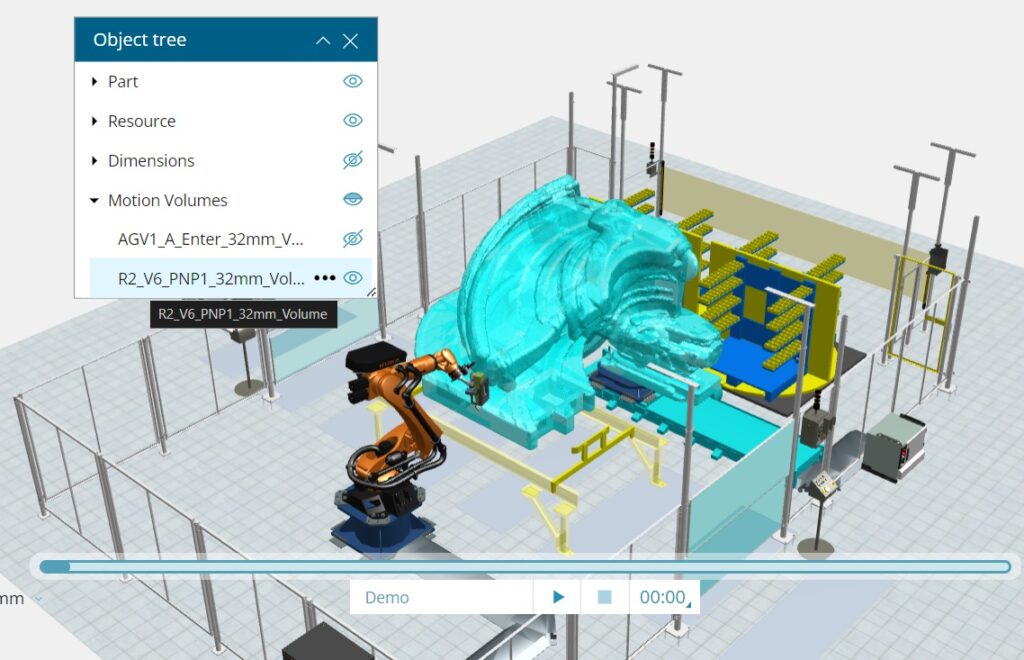

Motion volumes

You can manipulate the motion volumes of the objects in the study within Process Simulate Collaborate. This feature allows you to visualize the areas in a space where motion occurs such as collision detection, measurement and simulations.

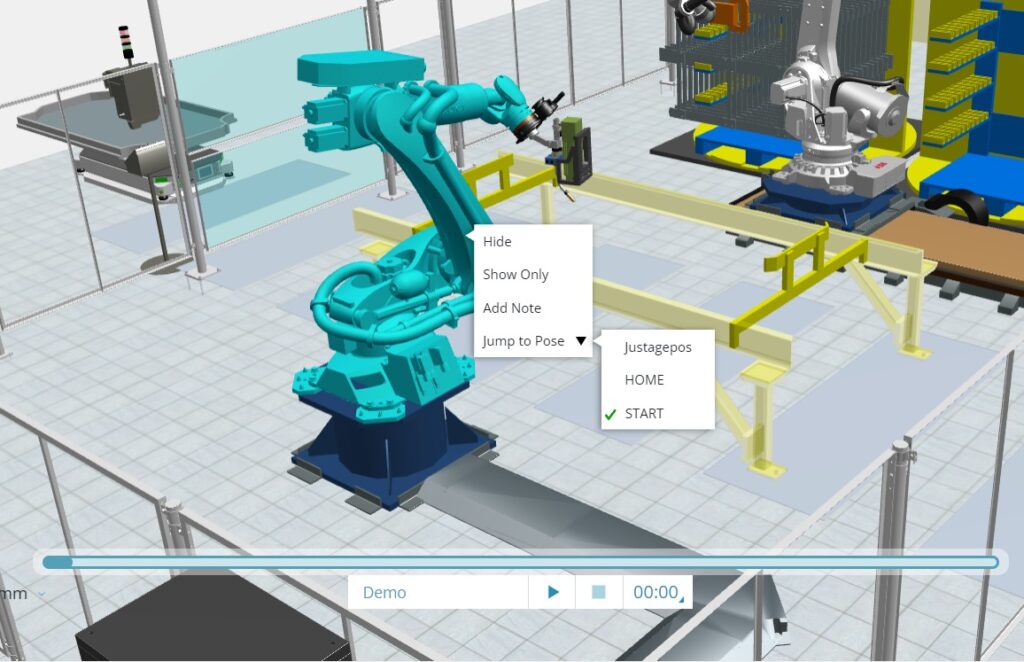

Jump to pose

You now can work with the kinematics of any device in Process Simulate Collaborate. This capability allows you to visualize various orientations and poses created in the study to accelerate the simulation review process.

Concurrent review

The concurrent review allows Process Simulate Collaborate owners and reviewers to work simultaneously. Reviews can visualize the study from any device to provide independent review feedback.

Robotics

Process Simulate Robotics helps you to program and validate your robotic processes in a dynamic 3D environment. It includes robotics applications for spot welding, metal processing, drilling and riveting, surface treatment and assembly.

The following new capabilities were released in Tecnomatix 2402.

Robot library

In Tecnomatix 2402, the introduction of the robot library viewer ushers in a new era of excitement and efficiency for you with a cloud-based robot library. This immersive experience provides a comprehensive collection of robot models, available in JT format, enabling a hassle-free approach to acquiring the robotic assets needed for simulation. Access the library online and seamlessly download robot models from within Process Simulate.

Easily navigate the cloud-based robot library which consists of an extensive collection of diverse robot models from leading vendors. The search functionality is equipped with built-in filters and text search capabilities, transforming the process of finding the correct robot model quickly and intuitively. Then, you can seamlessly insert the chosen robot into your loaded studies, eliminating any friction in the simulation setup process. With hundreds of new models available at your fingertips, you can find the best match for your specific simulation requirements.

You can also request new models directly from Siemens, providing a responsive environment that caters to your evolving simulation needs. The cloud-based nature of the library ensures that the excitement continues with new additions, updates and changes immediately available to all users.

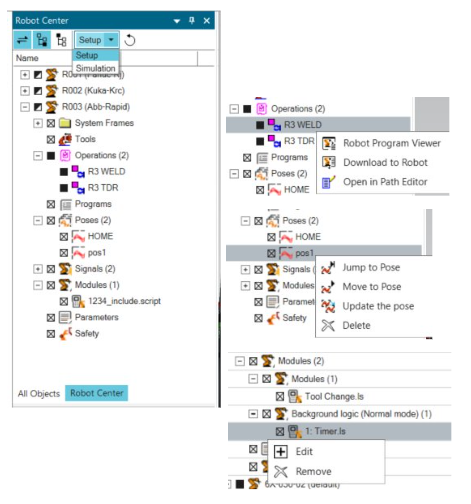

Robot Center

The latest updates to the Robot Center ensure an intuitive experience for both robotics experts and new users by centralizing all robots in the study and associated features in one place. With Tecnomatix 2402, there is now direct access to all robot-related features in a well-organized viewer. This streamlined interface consolidates tools for each robot in a study, minimizing the need to navigate through multiple tabs and improving the learning curve for new users with a consistent interface. The grouping of robot modules and background logic further optimizes accessibility, ensuring that all related actions are readily available.

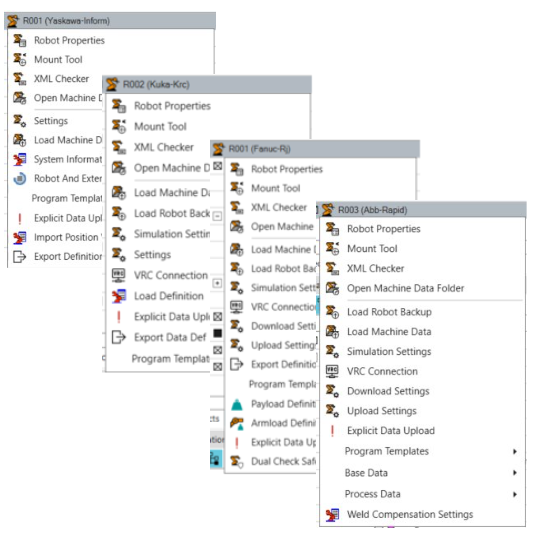

Supported controllers

The supported robot controllers introduce a significant advancement with full compatibility for Fanuc, Yaskawa and Kawasaki controllers, while ABB and KUKA enjoy extensive support, with plans for further expansion. The controller support is seamlessly integrated into the OLP package, allowing for real-time updates without waiting for the next Process Simulate release or software update.

Additional features include the ability to blank/display and the integration of controller settings into the Robot Center, streamlining the user interface. You can expect enhanced efficiency and adaptability, ensuring up-to-date controller support and consolidated settings.

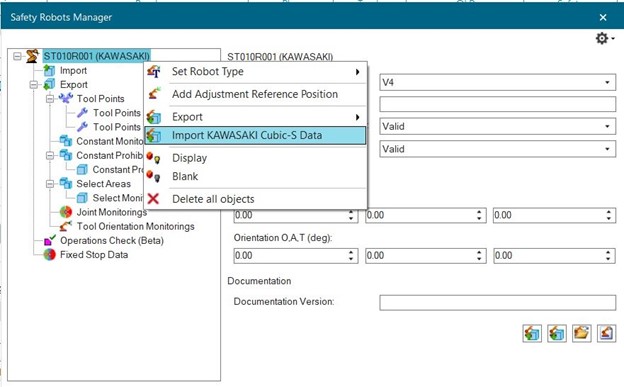

Safety Robot Manager supports Kawasaki Cubic-S

Tecnomatix 2402 introduces expanded safety robot support, now including the Kawasaki Cubic-S to enhance safety evaluation capabilities. You can also explore operation check, a powerful tool that allows users to evaluate multiple or all operations related to a robot, offering control for active zones. This tool provides a thorough report table, showcasing the evaluated operations and their results, exportable to Microsoft Excel. Operation check also utilizes the collision detection engine, potentially yielding varied results compared to regular safety breach simulations.

For a comprehensive review of Safety Robot Manager capabilities, check out our latest blog.

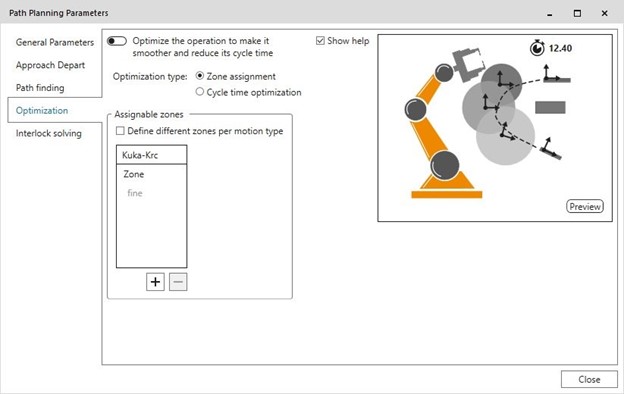

Robotic automatic path planner

Tecnomatix 2402 introduces the new Robotic Automatic Path Planner, a major evolution from its predecessor. This new tool is designed to enhance path planning for robotic operations, supporting functions like welding, pick and place, and addressing interlock challenges within the same sequence. Integrated with the path editor, the planner calculates collision statuses and offers a detailed monitor, providing you with a comprehensive understanding of your operations.

While currently in beta, the Robotic Automatic Path Planner is already making waves and user feedback is actively sought to refine and optimize the tool before its official release.

Virtual commissioning

Process Simulate Virtual Commissioning helps you to run the PLC code that controls the station to validate robot motion, robot logic and other mechatronic components such as clamps, conveyors and the entire process sequence. Virtual commissioning works with real PLCs (hardware in the loop, HiL) or virtual PLCs (software in the loop, SiL) and with the Process Simulate Cyclic Event Evaluator/Emulation (CEE) internal evaluation tool.

The following capability was released in Tecnomatix 2402.

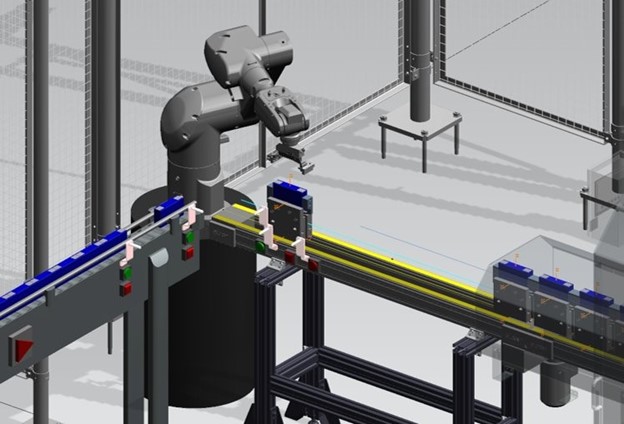

Skid and part simulation

Tecnomatix 2402 introduces a significant advancement in conveyor simulation with the skid and part simulation feature. Now, skids and conveyable parts seamlessly stack up when moving between conveyors, offering improved physical simulation with enhanced accuracy and reduced modeling effort. A notable improvement allows parts and skids to be controlled by separate conveyors to support stacking, eliminating the need for extra modeling steps. Furthermore, parts or skids halted on stopper control points are intelligently marked as “pickable,” streamlining interactions with other equipment like grippers. This not only enhances simulation realism but also significantly simplifies the modeling process.

Human simulation and virtual reality

Process Simulate Human helps you to eliminate any risk to operators with walk path analysis, reachability tests, vision analysis, and ergonomics assessments.

Process Simulate Virtual Reality delivers an immersive virtual reality environment for better engineering reviews, staff training and realistic process validation.

The following new capabilities were released in Tecnomatix 2402.

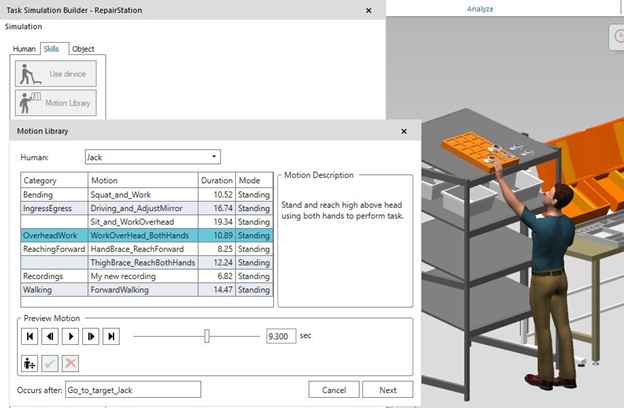

TSB motion library

Tecnomatix 2402 introduces the TSB motion library, empowering you to create custom motion sets for the task simulation builder (TSB). This feature allows the recording of motions directly from motion capture data or simulations, capturing the nuances of real human behavior. You can seamlessly integrate these motions into TSB, enhancing simulation realism and efficiency. The key benefit lies in the significant time savings during simulation creation, coupled with the ability to improve the authenticity of simulations by incorporating motions derived from real human activities.

Furthermore, you can edit individual postures within the added motions, refining tasks to achieve an enhanced and more accurate simulation experience. The TSB motion library streamlines the simulation creation process and facilitates collaboration by letting you share custom motion libraries with your colleagues. This feature marks a leap forward in simulation realism and efficiency, offering you a dynamic tool to enhance your simulation workflows.

Posture monitor: figure highlighting

Tecnomatix 2402 introduces a posture monitor within Process Simulate Human that highlights the figure designed for the study of human postures. This tool provides a quick and real-time assessment of ergonomic compliance during tasks. Numeric values for each joint angle are dynamically displayed in the posture monitor dialog, aiding you in identifying if task demands align with recommended limits.

In this version, a significant enhancement is the direct highlighting of postural warnings on the human figure within the scene. Colored spheres now vividly indicate when individual joints deviate outside preferred posture ranges, providing you with an intuitive and immediate visual cue. The key benefit lies in the seamless integration of real-time feedback, allowing you to enhance ergonomic assessments efficiently and make informed decisions, ultimately contributing to a safer and more ergonomic work environment.

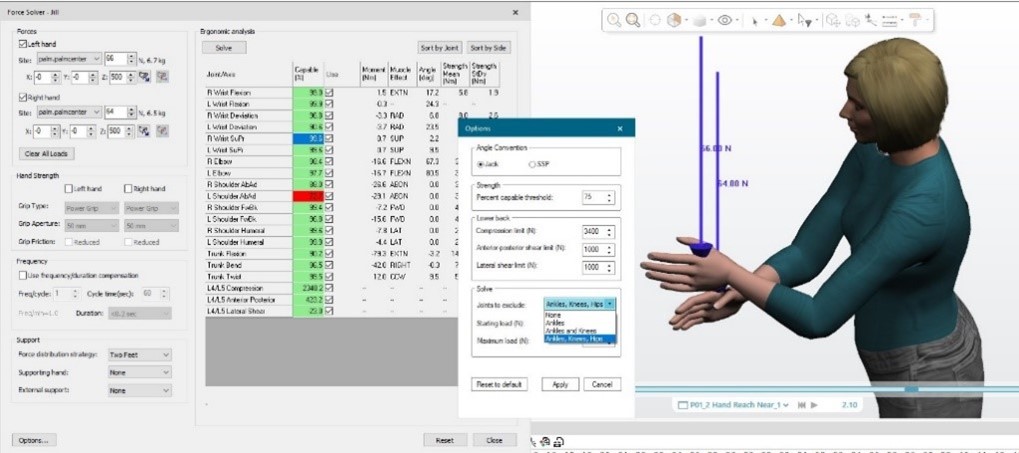

ForceSolver usability enhancements

Tecnomatix 2402 brings significant usability enhancements to the ForceSolver feature, offering improved flexibility and tailored analysis results. You now can exclude lower limb joints that are not relevant for your analysis, allowing for a more focused examination of task demands.

The key feature is the inclusion of new options in ForceSolver, enabling you to customize results for each scenario. This means that if an analysis specifically concerns the upper body, you can selectively exclude portions of the lower body, such as the ankles, knees and ankles, or ankles, knees and hips. The key benefit lies in the ability to generate highly focused analysis results, facilitating clearer insights and reducing potential confusion when sharing findings with others. TheForceSolver usability enhancements empower you with greater control over their analyses, ensuring precision and efficiency in ergonomic assessments.

These are just highlights of the advancements delivered with the latest Tecnomatix release. For complete details on the new features of Tecnomatix 2402 and its supporting releases, please refer to the release notes and new features presentations offered with the software download.

Don’t forget to join the Tecnomatix public community and explore the website for even more exciting developments.

Yours in digital manufacturing,

Kelly

(on behalf of the entire Tecnomatix product team)

You don’t have Tecnomatix software?