Inside Automated Assembly Systems and Simulation Technologies with SME Manufacturing Engineering and Siemens [ARTICLE]

Explore the discussion between SME Manufacturing Engineering and Siemens Digital Industries Software where Josh Carlson, Siemens technical product manager for robotics and automation, conveys the future of automated assembly systems and the emerging technologies for simulation software, including Siemens Tecnomatix Process Simulate.

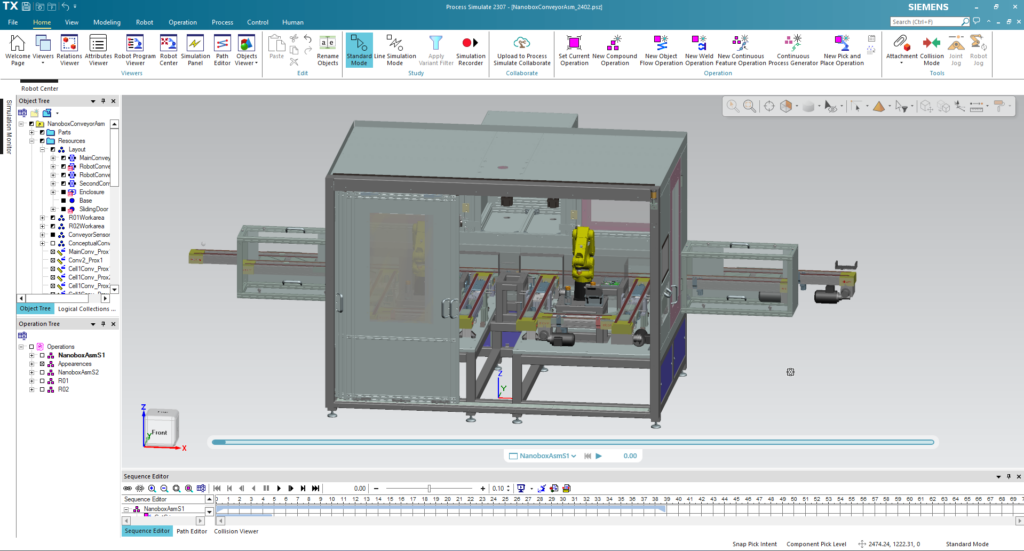

In the article, Carlson dives into the intricate world of automated assembly systems with practical application examples, highlighting the importance of verifying manufacturing processes in 3D environments with industry leading software like Process Simulate. As automation systems become more intricate, the reliance on an integrated platform becomes critical, enabling predictability in performance and mitigating increased costs and lead times.

Meet Siemens expert

Explore the complexities in modern manufacturing landscapes, specifically how virtual commissioning can help advance manufacturers opportunity to implement sensors and advanced systems such as vision-based solutions for robotics. These solutions will only help manufacturers take advantage of the Industrial Internet of Things (IIoT) revolution to help improve remote control, monitoring, and data collection.

Navigating DFA with integrated simulation technology

As discussed in the SME article, automated assembly systems are bound by contracts specifying target cycle times and failure to meet these benchmarks can be detrimental. The often-overlooked critical factor is the significance of design-for-assembly (DFA). Therefore, embracing DFA principles and integrated design and manufacturing software like Process Simulate remains the cornerstone for ensuring the efficiency of automated assembly systems. Carlson reinforces the importance of efficient engineering practices such as using advanced simulation tools and the reliance on the digital thread to streamline the assembly process.

Consider simulation,” Carlson says. “If you have a digital twin of the machine early on in the design process, it allows you to evaluate everything about that machine — its load-bearing capabilities, the sensors and motion control and other electronics, its conveyance systems and operator ergonomics — long before you’ve begun ordering the components, hardware and metal needed to build it.

Josh Carlson, Siemens Digital Industries Software technical product manager for robotics and automation

Siemens simulation software plays a pivotal role in assessing machine capabilities long before the physical commissioning on the shopfloor commences. Carlson stresses the inherent challenges in automated assembly machine building, where physical prototyping opportunities are limited. Therefore, the reliance on virtual prototyping through digital twins becomes imperative to ensure that electrical, mechanical, software, and integration teams are synchronized to meet project requirements.

![Process Simulate Collaborate: Enhanced Efficiency in Robotics Simulation [VIDEO]](https://blogs.stage.sw.siemens.com/wp-content/uploads/sites/7/2023/06/PSC2-395x222.jpg)