Siemens simulation software powers Continental’s digital manufacturing journey [VIDEO]

The realm of smart automation is complex and encompasses the integration of advanced technologies and intelligent systems to enhance and automate industrial processes. Explore the convergence of simulation and smart automation between Siemens Digital Industries Software and Continental, a major player in automotive technology, dedicated to sustainable and connected mobility solutions. Explore how Siemens simulation software in the Tecnomatix® portfolio powers Continental’s digital manufacturing transformation. Dive into the intricate world where Process Simulate and Plant Simulation help coordinate a symphony of efficiency for Continental.

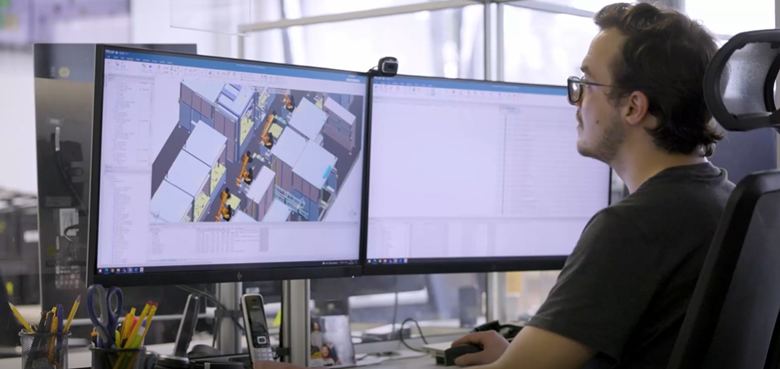

Founded in 1871, Continental is renowned for pioneering technologies that ensure safe, efficient, intelligent and affordable solutions for vehicles, machines and transportation. Jakub Hamerník, Continental’s Smart Automation Manager, sheds light on the profound impact of how Siemens software enables seamless digitalization on the shop floor, transforming processes and applications to enhance production timelines and efficiency. Siemens and Continental, long-time collaborators in PLCs and control systems, have deepened their partnership in recent years, particularly focusing on simulation. A pivotal aspect of this collaboration is the development of the digital twin factory, specifically the collection of production line data for future optimization, tracking and analysis, which is where the process planning starts.

A new standard: a collaborative approach to manufacturing efficiency

Central to this partnership is the challenge of streamlining the process flow from raw material to the end of production. Siemens simulation products play a critical role in providing comprehensive process information well before the production line delivery. This marks a significant departure from the previous norm, where engineers spent three to five years on the task. With Siemens, this duration has been slashed to a remarkable one and a half years, setting a new standard in the industry.

Thanks to the Siemens products, we have all relevant information from the process point of view prepared months before the delivery of the production line. Before, the engineers would take 3-5 years to make it. Now we are able to make it in 1.5 years.”

Jakub Hamerník, Continental, Smart Automation Manager

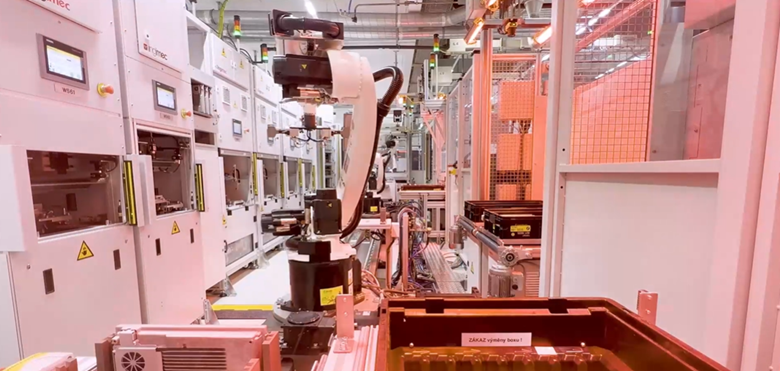

In a dynamic environment where original equipment manufacturers (OEMs) frequently update their car models, Continental recognizes the imperative to deliver new products efficiently and timely. Siemens software solutions enable Continental to meet these demands, facilitating the optimization of overall equipment efficiency (OEE) on production lines. With real-time access to operational data insights, engineers can easily track and adjust the manufacturing environment as needed.

Continental’s vision extends beyond the production floor, aiming to integrate Siemens’ products with their manufacturing execution system (MES) and enterprise resource planning (ERP) system. The goal is to establish a complete digital twin of the factory, effectively bringing IT applications to the shop floor. This comprehensive approach will provide insights into the entire end-to-end process, enabling real-time monitoring of goods, production progress and delivery timelines.

From concept to reality: Siemens and Continental’s strategic partnership

A moment of revelation for Continental occurred when its production line seamlessly transitioned without collisions. The simulation-derived cycle time was accurate, allowing Continental to commence production immediately after activation—a ‘wow effect’ resonating with both Jakub and Continental management.

Continental views Siemens not just as a supplier but as a strategic partner. The collaboration continues to evolve, with Continental actively working with Siemens to incorporate new features into their software, unlocking fresh possibilities for process improvement. This ongoing partnership exemplifies the commitment to pushing the boundaries of digital manufacturing for a more efficient and connected future.