What’s new in Plant Simulation? (January 2022)

Next-level optimization with Tecnomatix digital manufacturing.

Plant Simulation in the Tecnomatix® portfolio of digital manufacturing software optimizes manufacturing by modeling and simulating scenarios for production systems and their processes. With Tecnomatix Plant Simulation you can build simulation models reflecting your real shop floor in a digital model. The simulation models run fast and are reliable along a virtual timeline and can generate key performance values in the same way that your real production system does. According to those results, you can make your performance improvements and optimizations in early planning phases, where the production system is not yet built or available.

Plant Simulation product development covers several areas in parallel. For certain, we want to keep the leading position in the market of material flow and logistic simulation. Additionally, we are working on topics like PLM collaboration, virtual Commissioning, and web- and cloud-based use cases for material flow simulation. This blog post provides an overview of Plant Simulation enhancements in version 2201.

You might be asking yourself, what is 2201? The new version numbering for Plant Simulation, starting with this version, identifies the year in the first two digits, followed by the month in the second two digits for the current software delivery. In this case, 2022 and January, hence 2201.

We are excited to deliver this new release to you!

Don’t have Tecnomatix Plant Simulation? > Try it for free.

See the highlights from Tecnomatix Plant Simulation 2201:

> Siemens Teamcenter Share

> User interface

> AGV control

> SimTalk HTTP

> Fluid processing

> Value stream mapping

—–

Tecnomatix Plant Simulation with Siemens Teamcenter Share

To help customers of all sizes take the next leap forward in their productivity and gain additional competitive advantage, Siemens has introduced Siemens Xcelerator as a Service. This can significantly lower the barrier of entry for small companies and reduces IT costs for companies of all sizes by taking Siemens Xcelerator to the cloud. This expands our portfolio’s capabilities by making it more accessible, scalable, and flexible, and by making our portfolio and industry digital threads easier to access and implement.

For Tecnomatix Plant Simulation, there are four key benefits of using Siemens Teamcenter Share:

- First, there is the need for collaboration. Many manufacturing engineering teams today may not be participating in a formal managed environment. For them, Teamcenter Share is a good option to collaborate more effectively on production system modeling and simulation projects.

- Second, while they can use generic tools like email or web-based file sharing, these tools do not provide any specific advantage for engineering work. Teamcenter Share provides this additional context through capabilities such as simulation model sharing and viewing of production system throughput, material flow and logistics simulation results.

- Third, Teamcenter Share enables consistency in work across teams by ensuring that all teams are working with the correct version of data or models, process templates, material flow and throughput simulations.

- Fourth, Teamcenter Share allows decision makers to view and understand production system simulation model results more easily, anytime and on any device.

All these advantages are available to every Tecnomatix Plant Simulation user because the ability to work with Siemens Teamcenter Share is being built into every digital manufacturing solution. Teamcenter Share is packaged with all Plant Simulation products and provides cloud file storage for Plant Simulation data types. Plant Simulation with Teamcenter Share enables secure sharing of simulation models with colleagues outside of your company network and provides role-based access control.

Watch this video to see how Plant Simulation and Teamcenter Share work together:

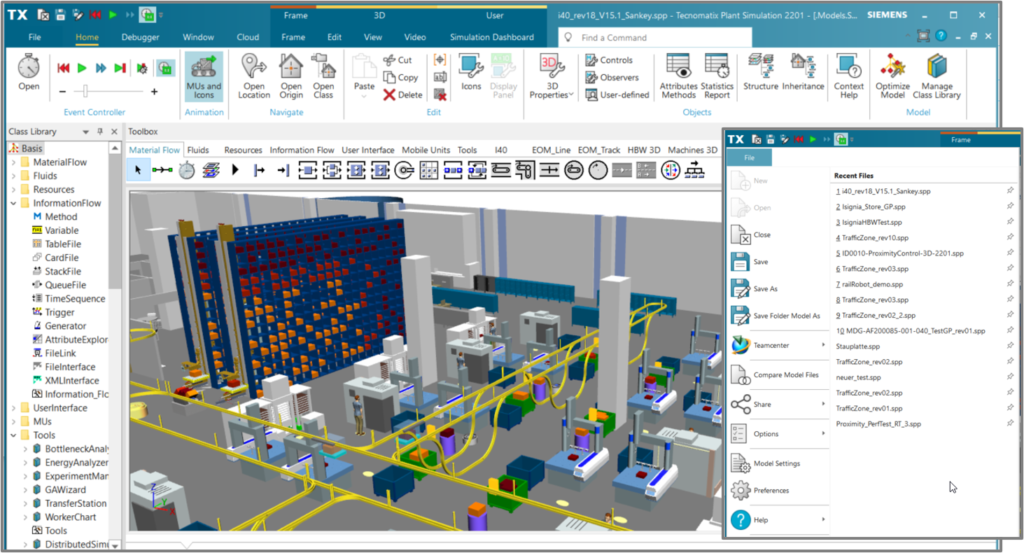

Plant Simulation user interface

Plant Simulation 2201 comes with a refreshed graphical user interface (GUI). It now has the same color scheme and standardized icons as the rest of the Tecnomatix digital manufacturing products. People should feel immediately at home when recognizing this look and feel in the new GUI.

AGV proximity control

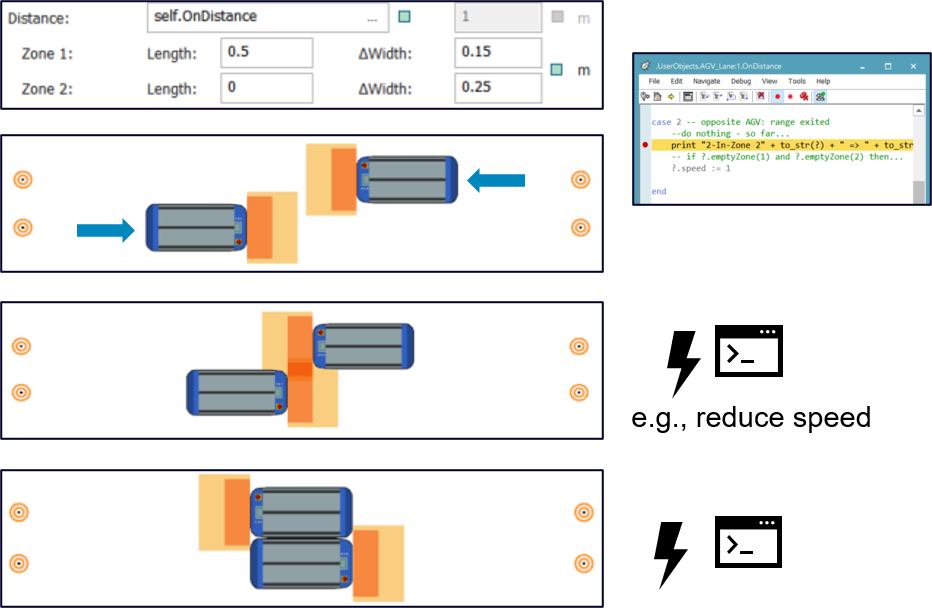

Plant Simulation 2201 provides two new sensor fields or distance zones to the free-on-the-floor moving transporter. A SimTalk method gets called once another transporter is entering or leaving a distance zone. With that, you can easily specify the needed transporter action. One typical action is stopping a transporter behind another that is waiting at a loading position. Another is to reduce the transporter speed in a two-way traffic situation.

SimTalk HTTP functions

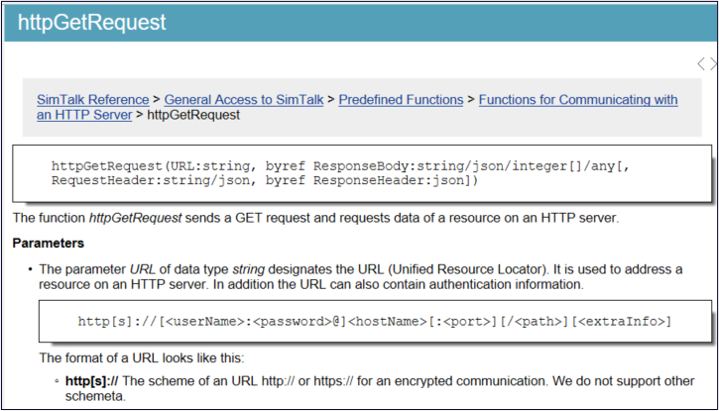

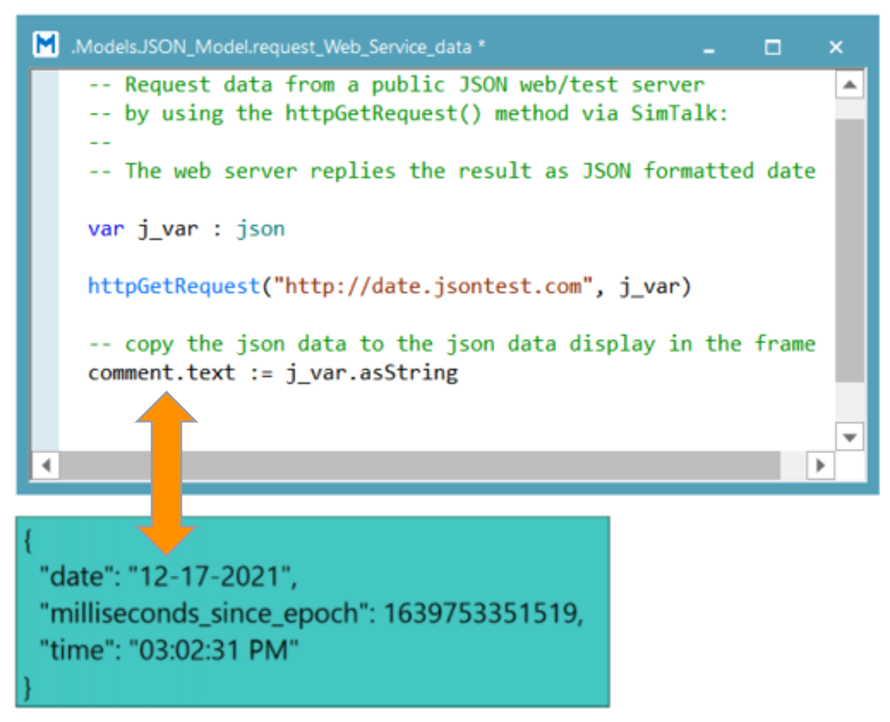

Version 2201 adds a set of predefined SimTalk functions for using the HTTP protocol to communicate with an external HTTP server. In the online help you will find all the details documented that you need for this type of server communication in a programming language, including syntax and parameter usage of this SimTalk interface.

Here you see a small example of a HTTP function call in SimTalk. It is a request for a timestamp from a public json test server. You can use the HTTP functions in SimTalk to request and send data.

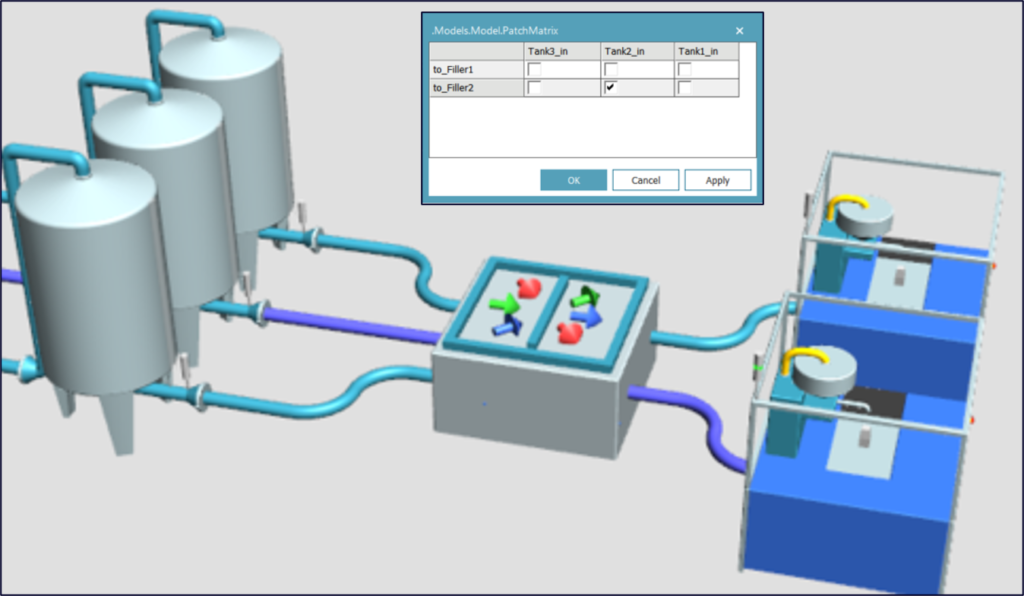

PatchMatrix object for fluid processing

In Plant Simulation 2201 you will now find the new fluid processing PatchMatrix object. This object simplifies the model building for common fluid manufacturing processes. According to production program changes you often must adjust the piping connection, for example, between fluid tanks and filling stations. The PatchMatrix object ideally supports and simplifies such piping changes in your simulation model.

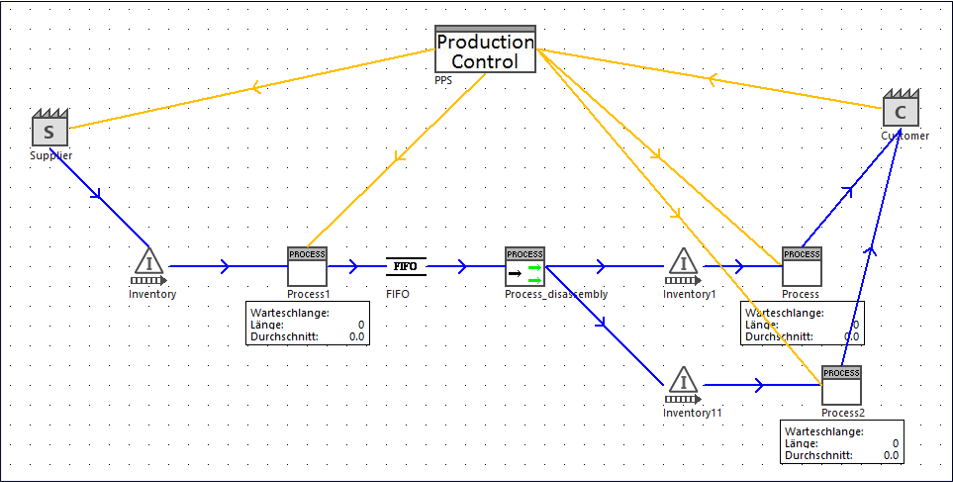

Value stream mapping library

The value stream library, developed by our partner SimPlan, has been extended in version 2201 by the Disassembly object as a common station type for manufacturing processes. This update also provides some additional statistics values to help you better understand and analyze the value stream simulation results.

—–

These are just some highlights of the many user experience advancements delivered with the latest release. For complete details on the new features of Tecnomatix Plant Simulation 2201, please refer to the release notes offered with the software download.

And, as always, hop on over to the public community, corporate blog, and website for all things Tecnomatix.

Yours in digital manufacturing optimization,

(on behalf of the entire Tecnomatix Plant Simulation product team)

Don’t have Tecnomatix Digital Manufacturing? > Try it for free.