Improve in-system test: VersaPoint test point technology

By Jeff Mayer – Mentor, A Siemens Business

Tessent VersaPoint test point technology is a new type of test point with two significant benefits: lower ATPG pattern count and improved LBIST test coverage. Why is this important? Because the rapid adoption of the ISO 26262 standard for functional safety requires targeting stuck-at test coverage of 90% or higher for in-system tests.

Tessent VersaPoint test points add up to 5% LBIST test coverage or allow designs to achieve 90% test coverage with up to 10x fewer LBIST patterns when compared with previous industry standard LBIST test point algorithms.

Many automotive IC design flows use a Hybrid ATPG/LBIST strategy. This turns out to be more efficient because the once-separate ATPG and LBIST technologies have merged to the point where compression IP is being re-used to apply BIST tests. The result is smaller test sets, higher fault coverage, and the integration of self-test required by the functional safety standard ISO 26262.

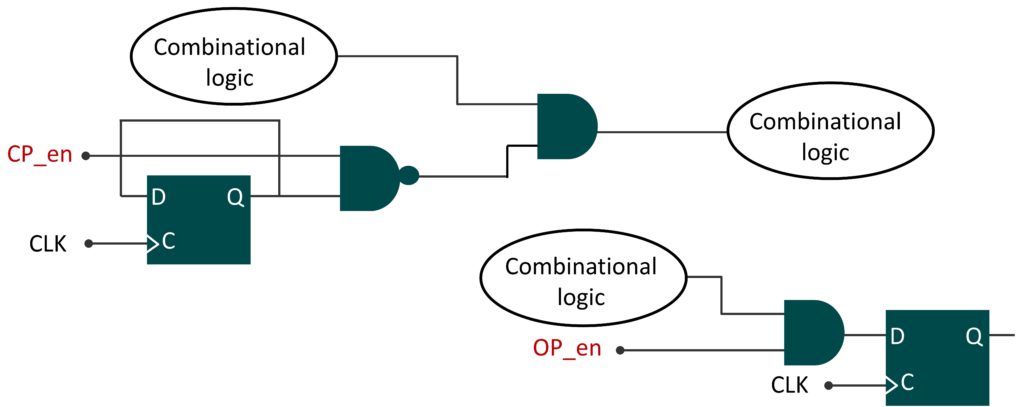

Test points are dedicated design structures used to improve the test results. Traditional LBIST test points improve results by addressing random pattern resistance in ICs. Mentor previously developed test points specifically for on-chip compression/ATPG, which reduces ATPG pattern count by 2-4X above what is achieved with on-chip compression alone. However, if you use a Hybrid ATPG/LBIST methodology, don’t you also want a more efficient test point insertion strategy? That’s where VersaPoint test point technology comes in; it combines and improves upon previous test point algorithms. VersaPoint test points work with Hybrid ATPG/LBIST with more efficiency than test points for either ATPG or LBIST separately.

We have seen significant across-the-board reductions in the pattern count needed to reach the 90% coverage goal in experiments using VersaPoint technology on industrial designs. When fault simulation was run up to 16k LBIST vectors, the average, improved coverage when using traditional LBIST test points was 5.6% higher than with no test points at all; using VersaPoint test points, the average coverage improvement is 9.5%. VersaPoint test points do a better job at both reaching 90% faster for in-system test as well as providing higher overall coverage when performing power-on-self-test.

Tessent VersaPoint test points are the best test point solution for ICs targeting automotive applications, allowing designers to target both high-quality manufacturing test with reduced pattern count and high-quality in-system test with reduced LBIST run-time and higher coverage than possible with no test points.

To learn more about using Tessent VersaPoint technology for improving in-system test, download this new whitepaper, Improving In-System Test with Tessent VersaPoint Test Point Technology. This paper explains how VersaPoint test points work and includes experimental data from industrial designs demonstrating pattern count reduction with VersaPoint technology.

Comments

Leave a Reply

You must be logged in to post a comment.

Hi there,

The link to the white paper mentioned above in your post doesn‘t work, I only get a message “page not found” (or similar).

Bernd