Three keys to finding the root cause of yield loss

An expert shares best practices for statistical analysis of scan diagnosis reports to ferret out the set of root causes.

Mentor’s Tessent yield diagnosis and analysis tools help manufacturers recognize, locate and fix design- and process-related yield problems to improve IC manufacturing quality. This best practices video from Mentor expert Jayant D’Souza demonstrates how to use the Tessent root cause deconvolution (RCD) technology to get the best diagnosis results from Tessent YieldInsight.

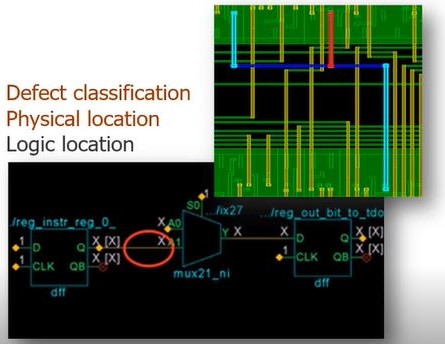

One problem with layout-aware diagnosis is the ambiguity or noise; analysis results may point to multiple locations and one single location could be explained by multiple root causes. For instance, an open in a particular net segment could be explained by an open defect in metal 2 of that segment, an open in metal3, a single via3, or a double via3.

RCD is a statistical enhancement technology that analyzes multiple layout-aware diagnosis reports to find the underlying defect distribution that is most likely to explain this set of diagnosis results. Where layout-aware diagnosis points to a segment, RCD can isolate a particular root cause in that segment. This enhanced diagnosis resolution increase the failure analysis (FA) relevance and success rate dramatically, reducing the FA cycle time from months to days. RCD also enables “virtual FA”, the ability to determine defect distribution for a population of failing devices before any failure analysis is performed.

RCD is built in to Tessent YieldInsight and available for all users. In this video, D’Souza demonstrates RCD best practices in three clear steps.