The value of the digital twin

By: Zvi Feuer and Zvika Weissman

Why is Siemens talking about the digital twin, and what can the value of the digital twin bring to industrial companies?

There can be many definitions of the digital twin. But in our point of view, a digital twin is a set of computer models that provide the means to design, validate and optimize a part, a product, a manufacturing process or a production facility in the virtual world. It does these things fast, accurately and as close as possible to the real thing – the physical counterpart. These digital twins use data from sensors that are installed on physical objects to represent their near real time status, working condition or position.

We at Siemens have recognized the value of the digital twin for a long time. When we began developing software for advanced robotics more than 25 years ago, we enabled full 3D models of automotive body assembly cells. These models could simulate, validate and optimize robotic operations before they were executed on the shop floor. With an extremely high degree of fidelity, our applications could not only simulate a cell, but enable its virtual commissioning almost to perfection.

Nonetheless, advances in computer science have made it possible to broaden the scope of the digital twin to include many more capabilities, information, inputs and outputs. It also helps you develop and introduce new products to the market much faster than ever.

Today, we can support digital twins for product design, manufacturing process planning, and production through the Smart Factory loop and via the Smart Product.

The full value of the digital twin can be realized through support for digital twins in product design, manufacturing process planning and production.

The full value of the digital twin can be realized through support for digital twins in product design, manufacturing process planning and production.

Deploying a digital twin

A classic deployment of a digital twin includes three pillars: in product design, in manufacturing process planning and in feedback loops.

1. In product design. A digital twin includes all design elements of a product, namely:

• 3D models (using CAD systems)

• System models (using system engineering product development solutions, such as systems driven product development)

• Bill of Materials

• 1D, 2D and 3D analysis models (using CAE systems such as Simcenter)

• Digital software design and testing (using ALM systems such as Polarion)

• Electronic design (using systems such as Mentor Graphics)

Using these elements results in a comprehensive computerized model of the product – enabling almost 100 percent of virtual validation and testing of the product under design. All of this eliminates the need for prototypes, reduces the amount of time needed for development, improves quality of the final manufactured product and enables faster reiteration in response to customer feedback.

2. In Manufacturing Process Planning. The Siemens solutions available today can enable the development of three models critical to any manufacturer:

• Manufacturing Process model – the “how” – resulting in an accurate description as to how this product will be produced.

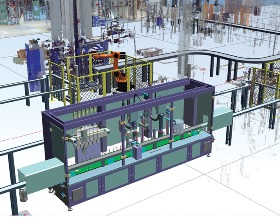

• Production facility model – providing a full digital representation of the production and assembly lines needed to make the product.

• Production facility automation model – describing how the automation system (SCADA, PLC, HMI, etc.) will support the production system.

The value of the digital twin in manufacturing offers a unique opportunity to virtually simulate, validate and optimize the entire production system. It also lets you test how the product with all its primary parts and sub-assemblies will be built using the manufacturing processes, production lines and automation.

Within this digital twin, we can also incorporate the logistics aspects. The digital twin of the in-process logistics systems can help planning teams design an effective sideline logistics solution to feed the production lines. Process logistics could be part of the manufacturing process’s digital twin and also the physical part of the logistics system.

The automated guided vehicles, the racks, the box and the conveyers would be part of the production system’s digital twin – that is, the ‘smart factory.’

We must emphasize that while smaller organizations might not need all the elements of a digital twin, even smaller manufacturing companies have some elements that will become critical. Without those, a small, agile manufacturer won’t be able to continue to succeed against its competition.

The value of the digital twin in manufacturing? It gives you the opportunity to virtually simulate, validate and optimize whole production systems.

The value of the digital twin in manufacturing? It gives you the opportunity to virtually simulate, validate and optimize whole production systems.

3. In feedback loops. There are two feedback loops which have a huge impact on most manufacturers – the Smart Factory loop and the Smart Product loop.

Smart Factory loop. The feedback loop starts with the Smart Factory. This is a fully-digitalized factory model a production system connected via sensors, SCADA systems, PLCs or other automation devices to the main PLM data repository. In a smart factory, all events on the physical shop floor during production are recorded and pushed back to the PLM system directly or through a cloud. Artificial intelligence technology studies and analyzes this information, and the main findings are sent back to either Product Development of Manufacturing Planning or to facility planning.

Why is this important? About only one week after start of production, the production facility and the manufacturing process will change. New ideas will be implemented, new working methods will be deployed and new suppliers might be selected – all requiring changes to the production system or process. Since these modifications will certainly impact the future, updating them in the system at this stage is becoming a must.

Production systems outlive the product lifecycle, and many of our customers use their production systems to make multiple products. These factors contribute to the increasing need to regularly capture these changes in the PLM system, which can later distribute this information to all parties.

The information collected during production can also serve as the basis for improving the maintainability of manufacturing resources. With this information, we can enable much better (sensor) condition-based maintenance, and thus increase uptime and productivity.

Smart Product loop. Almost every product made today is a Smart Product. Many of our customers are looking for ways to improve the connection with their Smart Products while they are being used by their customers!

Monitoring product usage can provide a lot of knowledge for improving products in the future. More than that, connecting to these Smart Products can generate a new type of business model that may result in more competitive offerings.

For example, aircraft engine producers can vend “flying time” rather than directly selling its engines. When an airline company buys engine “flying time,” it ends up spending less of its capital budget and even gets better service, benefiting from the manufacturer’s commitment to provide a higher level of service maintenance. The engine manufacturer only gets paid when the engines are in actual use, so it has to ensure it constantly monitors its engines, offer advice on how to use and service those engines, and even do some of the maintenance, repair and overhaul work.

You can find Smart Products everywhere. For instance, we have a customer who produces heavy-lifting cranes. A few years ago, the customer modified its products to become smart cranes. The company’s end customers can buy hourly “lifting power” rather than buying actual cranes. Through installed sensors, the company collects usage information and then provides the end customers with feedback on how to use the cranes to achieve a longer lifecycle and more lifting power.

The value of the digital twin is further seen in the Smart Factory loop and the Smart Product loop.

The value of the digital twin is further seen in the Smart Factory loop and the Smart Product loop.

Here’s the bottom line about the value of the digital twin: a digital twin enables flexibility in manufacturing to reduce time needed for product design, manufacturing process and system planning and production facility design. A digital twin improves quality and even supports new business models that offer opportunities for small- to mid-size companies to expand and bring more high-tech capability into their shops.

Digital twins will help all companies become more flexible, reduce time to market, reduce cost, improve quality and increase productivity at all levels of the organization.

This concludes part one of our series on the value of the digital twin. In part two, we answer some of the most frequently asked questions about the growing value of the digital twin and implementing the digital twin in your business.

About the authors

Zvi Feuer is senior vice president of Manufacturing Engineering Software for Siemens PLM Software, a business unit of the Siemens Digital Factory Division. He has more than 25 years of experience in Enterprise Software business management, with a primary focus in the Manufacturing Industries. He has worked for: the Israeli Aircraft Industries (IAI); Digital Equipment, a leading provider of hardware and system integration projects; and since 1995, with Tecnomatix, UGS and Siemens. Feuer’s current responsibilities include leading global teams and initiatives to develop and service customers worldwide and providing Manufacturing Engineering Software solutions. These solutions include optimizing production and service facilities, assembly line design, developing and validating production systems and programming CNC machines in major machine shops. Feuer received his Master of Science in industrial engineering from Technion – Israel Institute of Technology, and also received an executive MBA from UCLA – NUS.

Zvika Weissman has more than 15 years of experience in the PLM market, dealing with Digital Manufacturing Software tools business development, marketing, engineering and support. He is currently the aerospace and defense Business Development Director, in the Siemens Industry SW Manufacturing Engineering SW Solution segment. In his previous role, Weissman helped deploy Digital Manufacturing tools within leading automotive, aerospace, machinery and consumer goods companies in the U.S., Europe and Asia Pacific. In this role, he gained special expertise in using digital manufacturing planning and simulation tools such as Teamcenter Manufacturing Process Planner, Process Designer, Robcad, Process Simulate and Plant Simulation. He analyzed companies’ business and engineering processes and developed workflows to establish as part of the companies’ continuous improvement processes. Weissman holds Bachelor’s degree and a Master’s degree in Mechanical Engineering from Technion Israeli institute of Technology, and a Master’s degree in Business Administration from Tel-Aviv University.