Essential Industry 4.0 manufacturing capabilities

Industry 4.0 manufacturing has companies talking, and for good reason. The idea behind Industry 4.0 – being able to create agile, adaptive manufacturing networks that can respond to rapid market fluctuations – is an important part of how manufacturers will retain success as they move into a new Industrial Revolution.

Creating systems with these capabilities won’t be easy. Industry 4.0 manufacturing requires companies to include new capabilities that provide tools to learn from products while they’re in the field, to understand consumers’ voices and trends and to predict shifts in market preferences. To make sure all of this is possible, manufacturers must also be able to incorporate the Internet of Things throughout its processes.

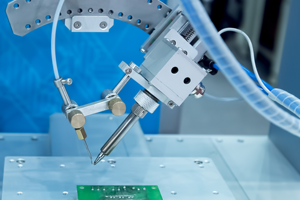

In this series, we’ve discussed how speed and the orchestration of advanced automation are critical capabilities to include in your processes as Industry 4.0 becomes a reality. We continue that conversation now as we look at other necessary capabilities in the fourth Industrial Revolution – connection and insight.

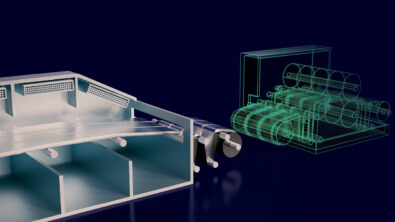

Connection. Connection takes on new meaning in Industry 4.0 manufacturing. Connection is required to harness the power of the entire infrastructure’s intelligent nature. Even the most brilliant innovations in automation can only deliver a local benefit if it’s only operating on an island. In fact, cells of automation that focus on optimizing a local plant or an individual line can actually hurt overall performance if they aren’t synchronized with the overall operation – what lies in the realm of the Manufacturing Execution System, or the MES.

Maximizing throughput on a line that feeds a slower operation can generate additional work-in-process inventory. In that case, excellent automation on an island won’t increase final production rates; it will actually increase the amount of capital tied up in inventory, which affects the overall economics of a business and its ability to fund growth initiatives.

In addition, the connectedness of the manufacturing process means improved traceability and reproducibility – the process by which actual production problems can be isolated and resolved.

Yet orchestrating the production process is only the first place connection should be for Industry 4.0 manufacturing. There should be a connection throughout the entire supply chain and, perhaps most importantly, there is connectivity with the consumer. Companies that can capture true market intelligence to guide the development of innovative products, if they operate efficiently at the same time, will emerge as market leaders.

With so much more information about trending consumer preferences available across social networks and from smart products themselves, you will be introduced to entirely new sets of data to feed product improvement and next-generation products.

Implied by the “Internet” of Things, connectivity is an essential element of the Industry 4.0 enterprise. Determining what you need to connect, and orchestrating internal and external connectivity, is something innovative industries must be working toward today if they want a successful future.

Connectivity is essential to successful Industry 4.0 manufacturing processes.

Connectivity is essential to successful Industry 4.0 manufacturing processes.

Insight. Speed, advanced automation and connection all impact a manufacturer’s ability to compete in Industry 4.0 manufacturing. But companies also need insight to ensure these capabilities will work well together.

We know that data is a huge element of Industry 4.0 manufacturing. We have intelligent machines and automation systems giving us not only their own up/down status, but also information about material, process, throughput performance and maintenance requirements.

We have intelligent products giving us information not only about working/not working status, but also how and how much it’s being used. We also have nodes of the supply chain that can signal to us whether we should make alternative sourcing decisions. And, we have consumer networks giving us data on their preferences.

But how does a manufacturer distill true insight from all of that data? How does a manufacturer understand true cause and effect from the combination of all of these data sources?

Of course, that’s the promise of Big Data. In the midst of this massive wealth of data, we can glean true insight that helps us understand the value of a product, the improvement opportunities of the product, how to most efficiently get that product to market and the opportunity to move the market to new levels of value.

Ultimately, companies that leverage Big Data technologies to harness the potential insight our intelligent network can provide, will lay the foundation for effective innovation, higher product quality and improved customer satisfaction.

Companies that use Big Data technologies to gain insight will have a huge advantage in Industry 4.0.

Companies that use Big Data technologies to gain insight will have a huge advantage in Industry 4.0.

This concludes our discussion of how connection and insight are two capabilities companies need to succeed in Industry 4.0 manufacturing. In our next part, we look at the two final capabilities manufacturers need to round out their capabilities in Industry 4.0.

About the author

With more than 20 years of experience, first as a manufacturer and then with Siemens, Alastair Orchard has focused on the gains in operational efficiency that Advanced Automation, MES and MOM delivery. He now focuses on Industry 4.0 and the consumerization of manufacturing. Alastair currently leads a global team running the Digital Enterprise Project to help customers take advantage of the synergies possible between product ideation, realization and utilization through the digital transformation of their business processes. Alastair holds an engineering degree in chemical engineering from the Loughborough University of Technology in the U.K. and lives in Genoa, Italy with his wife and four children.