Generative design exploits additive manufacturing processes

Additive manufacturing is about to become even more critical to manufacturers in highly competitive industries thanks to a relatively new design capability called generative design.

Generative design leverages algorithms based on previous design knowledge and high-performance computing to autonomously generate or modify design geometry based on requirements for or constraints on product performance.

Using generative design, engineers specify parameters, such as weight-to-strength ratios, efficient material use, and temperature, pressure and force ranges. The generative design software engine creates several design options through an iterative process similar to Mother Nature’s proven evolutionary approach to design. Engineers then evaluate and select from among the generatively designed options—more options than would be humanly possible with traditional design tools, and likely many options that the engineers would never have considered.

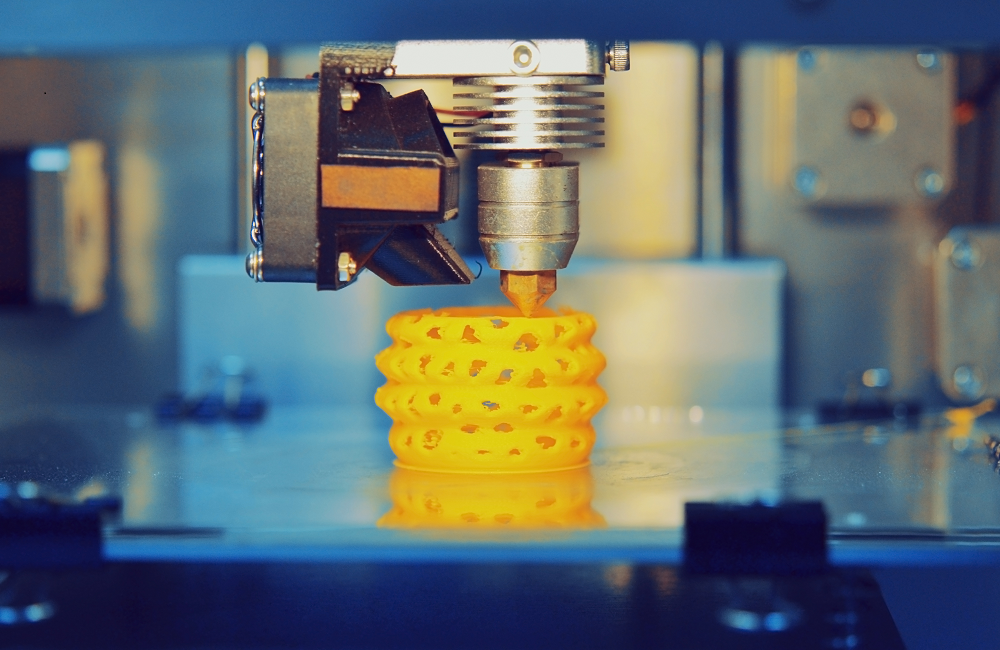

Together, generative design and additive manufacturing processes give engineers powerful tools that speed prototype, and finished part and tooling development and production; as well as imbue parts with unique characteristics or functionality.

Both generative design and the 3D printing process make possible entirely new geometries and topologies, including more organic designs than ever could be realized with traditional manufacturing. Many shapes coming from generative design are difficult or impossible to produce using traditional methods, while additive manufacturing processes can directly print these shapes.

In addition, by pairing generative design with additive manufacturing, companies can build products with optimum functionality. For example, many parts for aerospace and energy industry require materials that are heat resistant, which are expensive. Using generative design, manufacturers can experiment with designs that combine heat resistant materials close to the heat source with less expensive materials in areas that are not near enough to be affected by the heat source. Additive manufacturing processes can produce such a part.

First adopted as a solution for speeding the production of prototypes, additive manufacturing is fast becoming a driver of lower-cost final production and tooling because it can:

-

- Eliminate the need for expensive specialized machines or expensive tooling

-

- Use less material and creates less waste, which also reduces cost

-

- Require minimal special training for production operators

With the benefits of additive manufacturing processes proven, manufacturers increasingly are using it to produce high-performance parts. At the Siemens test center for industrial gas turbines in Lincoln, England, a team of experts reported the successful “full-load test” of gas turbine blades that were entirely produced using additive manufacturing.

Power generation is one of the most demanding environments. The blades must withstand extreme conditions inside a turbine, including high pressures, tremendous centrifugal forces and temperatures that reach 1,250°C when the turbine is in full operation. At full power, the blades rotate at 1,600 km/h and carry loads of 11 tons.

Because additive manufacturing is accessible and affordable for companies of all sizes, industry leaders are particularly at risk of new competition from midmarket manufacturers. Fusion3 is one producer that supports smaller companies with a $5,000 3D printer that is “engineered to build large parts, quickly” using “most any material that can be heated up to 300°C.”

Additive manufacturing processes, when paired with generative design, will become even more critical as design and production processes compress to meet customer demands for faster delivery of more complex, often customized products at lower cost.

Generative design and traditional manufacturing

Generative designs can also be used in traditional production environments and be 3D-printed, with the addition of another new design capability known as Convergent Modeling.

Generative design produces faceted, or mesh, models, while traditional design applications create b-rep models. With Siemens’ Convergent Modeling solution, engineers can perform b-rep modeling operations on facet bodies without conversion. It allows designers to combine facets, surfaces and solids in one model without converting data, previously a time-consuming, error-prone process.

Amazone, a German manufacturer of agricultural and municipal machinery, for example, employed generative design to redesign an originally welded suspension component. Generative design helps improve the weight and durability properties of the finished casted part.

An end-to-end solution compounds benefits

The power of generative design and additive manufacturing processes is compounded when adopted as part of an end-to-end product lifecycle management (PLM) strategy that integrates design, engineering, manufacturing and maintenance through unified solutions and data.

Indeed, generative design both uses and adds to product knowledge in the digital thread, as simulation results are stored, ready to be applied to optimize future designs.

Generative design, Convergent Modeling and additive manufacturing have become critical tools that support digitalized and team-driven lifecycle workflow. Manufacturers that must frequently and quickly deliver new and innovative designs of complex products, such as those in automotive, aerospace, energy, industrial machinery and heavy equipment, biomedical and electronics, must move quickly to adopt them.

This concludes part two of our series on multidisciplinary design. In part three, we discuss how teams armed with the right technology are transforming product design.

About the author

Tod Parrella is the product manager responsible for NX Design. He has worked in the NX Product Management organization for more than 11 years and is responsible for the development of a number of NX CAD innovations including Synchronous Modeling, NX Realize Shape Subdivision Modeling and most recently Convergent Modeling. Tod is also the Design lead for the NX Generative Design initiative which includes investments in Bionic & Lightweight Structures Design and Design for Additive Manufacturing. In addition to his role as Product Manager for NX Design, Tod also manages a small industry product management team responsible for driving industry requirements into the NX Design planning process.