Materials are the key to future car interiors

What role will materials play in future car interiors?

In the past, materials were all about luxury: fabric seats versus the finest Italian luxurious leather seat. Although luxury still plays a role in the future, other factors are creeping into the equation.

For instance, cars will need to have durability, an easy-to-clean interior that can last 100,000 miles and be on the road nearly 100 percent of the time. This is because cars won’t just be personally owned: they’ll be integrated into our roadway infrastructure as part of autonomous mass transit.

Integrating electronics in the materials will also pose issues for manufacturing and industry collaboration: companies with strengths in electronics will need to work more closely with traditional textile manufacturers.

This reimagining of what future car interiors will look like was the focus of my conversation with Paige Kassalen, a future of mobility market analyst at Covestro, a global leader in advanced polymers and high-performance plastics. In the initial parts of our conversation, Paige and I discussed how a previous project influenced her thinking of how future interiors could look in cars, as well as what the potential of customized travel experiences means for consumers.

Here, we discuss the literal melding of electronics and materials in the future car interior experience.

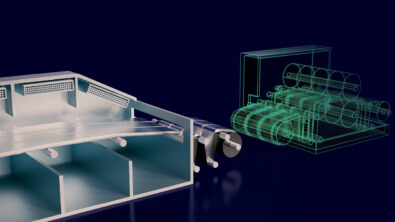

Edward Bernardon: You have a vehicle with a significantly flexible experience. I imagine that the materials are going to work hand-in-hand with the electronics. Or, maybe they’ll merge.

How do you see materials changing? How do you see materials working with electronics and interfaces with the passengers? How will that evolve? What’s that going to become to deliver these experiences?

Paige Kassalen: We see a shift with our materials where instead of providing more luxury or premium experiences, we’re considering our materials high value. That coincides with what you were saying, where we have to ensure that our materials will be durable for ride sharing.

If you’re having 100 people getting in and out of a car each day, and the car is doing 100,000 miles a year, that’s very different from how we design cars today. We’re verifying and adjusting our materials to meet those needs of the future.

That’s the same with customization.

We know that with people, sensors and electronics, it’s about how they work together. Are there ways in our textile coatings or our polyurethane seating foam to embed sensors ― biometric sensors ― into those components, and have one connected system inside of the vehicle?

Edward Bernardon: What about how you put these materials together? For example, when you sew a seat cover, it’s stitched together much like leather goods have been made for hundreds of years. How do you see the construction and the assembly of all this? It’s like you’re building an interactive computer or electronic device that you sit on.

Paige Kassalen: Yes, it goes precisely back to the unprecedented level of collaboration we see in this industry. Covestro sells raw materials, and we have to ensure that we’re working with electronics companies, and diverse automotive tiers, including different forms of digitalization companies that can help interpret the unmet needs for future demands. Then, relay that back towards how we’re developing our products.

If we’re inventing an entirely new product, it could take us years. So, we need to start now and collaborate with industry leaders to ensure that we’re positioned well for the future.

Edward Bernardon: What are the challenges to assist people in comprehending the importance of engineering the vehicle? Not just the electronic components, but engineering those components ― mechanical, electrical, in conjunction with interiors. Do partners understand that it’s essential, or do you see some challenges to conveying the importance of interiors?

Paige Kassalen: I think there are some challenges where even I, with a degree in electrical engineering, didn’t consider all that goes into materials and how they can make an impact. Part of my job is educating people on what different material solutions can do.

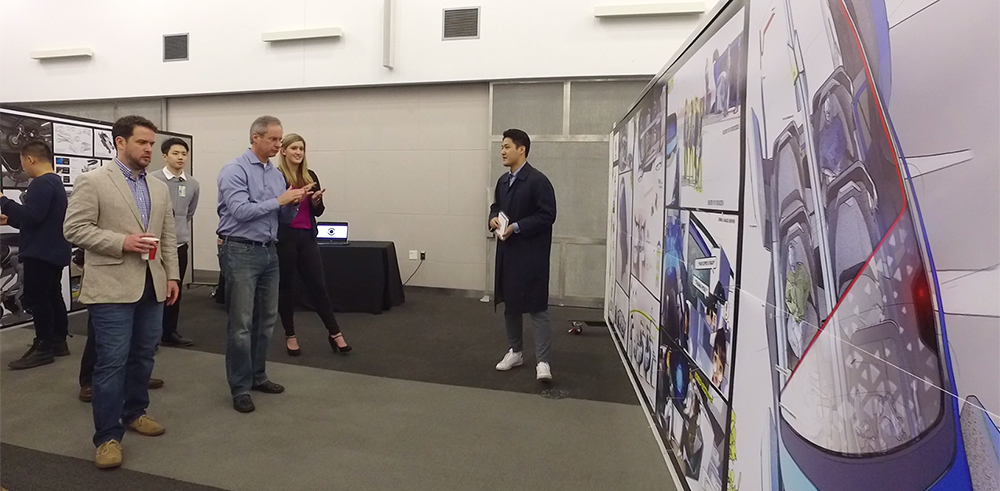

One thing that Covestro has done, including my team, is ensuring that we are positioning our materials to the tiers that are sales targets, to various companies and designers. That positioning of materials is a little bit different. We have material solutions in all three of our units – our polyurethane foams, our polycarbonate plastics and our coating’s unit – that can enable a seamless product.

In addition, sensors will be integrated around the vehicle on the exterior and interior to meet the demands of the designers with a sleek design, and also meet the demands of the engineer with everything functioning properly.

Edward Bernardon: How do you motivate a company to bring in people that understand interiors like this and work on a team? Do you see that currently happening?

Alternatively, is that something that will happen in the future? Are you trying to drive that with your partners when you interact with them and raise the importance of interior engineering and materials as they start to design these cars?

Paige Kassalen: I’ve seen more collaboration when I go out and talk with different people throughout the industry. A significant driver is that everybody wants to be first in this industry. They want to collaborate and accomplish a new design.

It’s the space race of the 21st century. This creates an atmosphere where people are willing to put away some of their pride in where they operate and see the big picture. I know that throughout the year and a half I’ve been in my position, it was a bit difficult to get people to start thinking of materials and interiors in the beginning. But now I hear conversations regarding it, without being prompted.

This concludes the third part of our series on autonomous vehicle interiors, a discussion with Paige Kassalen of Covestro. In part four, we’ll continue discussing car materials and the future of customizable travel experiences.

About the author

Edward Bernardon is vice president of strategic automotive initiatives for the Specialized Engineering Software business segment of Siemens PLM Software, a business unit of the Siemens Industry Automation Division. Bernardon joined the company when Siemens acquired Vistagy, Inc. in December, 2011. During his 17 year tenure with Vistagy, Bernardon assumed the roles of vice president of sales, and later business development for all specialized engineering software products. Prior to Vistagy, Bernardon directed the Automation and Design Technology Group at the Charles Stark Draper Laboratory, formerly the Massachusetts Institute of Technology (MIT) Instrumentation Laboratory, which developed new manufacturing processes, automated equipment and complementary design software tools. Bernardon received an engineering degree in mechanical engineering from Purdue University, and later received an M.S. from the Massachusetts Institute of Technology and an MBA from Butler University. He also holds numerous patents in the area of automated manufacturing systems, robotics and laser technologies.