Generative design for autonomous vehicles

Companies pursuing autonomous vehicle programs face a steep technological ramp that is rife with compelling technological challenges. Advanced sensor technology, high-speed and high-bandwidth data networks and cutting-edge artificial intelligence are all crucial to the functional and commercial success of autonomous vehicles (Figure 1). In addition to designing these complex systems, engineers must verify that they function and fail safely, both independently and as a cohesive system. To optimize the vehicle design, engineers must be able to quickly and efficiently incorporate lessons learned through simulated and real-world testing.

Figure 1: Autonomous vehicle platforms must connect an array of advanced sensors and computers through high-speed data networks to perceive, assess, and act on environmental stimuli.

A fully autonomous vehicle will have complete control over the driving task, requiring no human input. As a result, a fully autonomous car is projected to have more than fifty sensors to cover the immense number of tasks an autonomous vehicle will need to perform. To design such a vehicle, engineers will need to perform architecture and tradeoff analyses to investigate architectural proposals, such as a centralized versus domain versus distributed architecture. These analyses will need to account for hundreds of components and millions of signals while optimizing function locations, network latency, error rates and more.

Despite these challenges, autonomous drive is a burgeoning market. At least 144 companies have announced autonomous vehicle programs. Some of these are major automotive manufacturers seeking to stay ahead of the coming industry disruption, but most are startups or companies from other industries seeking to enter a traditionally impenetrable market. These companies lack industry-specific experience and the engineering resources to force their way through the complexities of autonomous vehicle design.

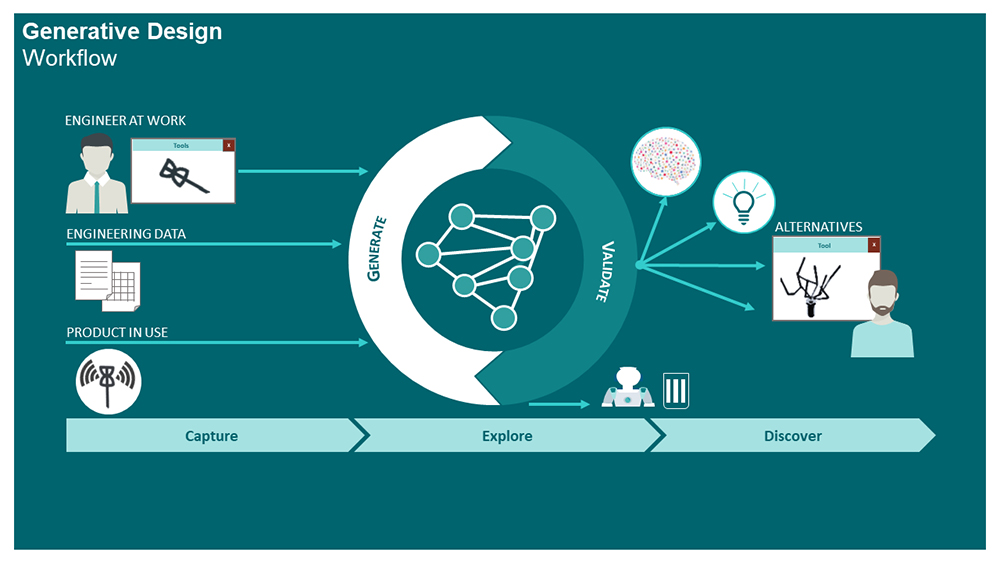

However, recent advances in engineering software are enabling engineers to tackle the challenges of electrical and electronic systems design for autonomous vehicles. Engineers can now adopt a methodology known as generative design, which enables rapid design synthesis, designing in the context of a full vehicle platform and tight integration between various domains to ensure data continuity.

Generative design takes system definitions and requirements as input and generates architectural proposals for the logic, software, hardware and networks of the electrical and electronic systems using rules-based automation (Figure 2). These rules capture the knowledge and experience of veteran engineers to guide younger engineers throughout the design. Capturing this IP helps companies to develop both vehicle architectures and new generations of engineers as they learn and implement existing company knowledge.Figure 2: Generative design uses rules-based automation to generate proposals for the logic, software, hardware and networks of the electrical and electronic (E/E) system.

Furthermore, employing automation throughout the process will help design teams manage design complexity without increasing time-to-market. Automation helps engineers focus on the most critical aspects of the design and verification of the functionality of the E/E system and reduces errors from manual data entry. By reducing the administrative aspect of the engineer, they are free to apply their creativity and ingenuity to creating the next generation of automotive technology breakthroughs.

Next, designing in the full platform context helps engineers to understand the way signals, wires, and other components are implemented across the entire vehicle platform, thereby reducing errors at interfaces or due to the intricacy of the harness. This design flow also enables teams to re-use validated data across vehicle platforms to improve quality and reduce development costs.

Finally, a tightly integrated environment enables electrical engineers to share data with engineers and tools in other domains, such as mechanical or PCB design. The interactions between the electrical, mechanical and software components of a vehicle are increasing. Seamless synchronization of data between these domains improves the integration of them into a single system.

The massive complexity inherent in autonomous vehicle design will continue to push the tools and methodologies used by automotive engineers. This is especially true in the electrical and electronic systems domains as they come to dominate the operation of a vehicle’s safety-critical systems and amenities. Generative design will enable the winners in this disruptive technology by helping them effectively integrate the advanced technologies required for autonomous drive into a package that is reliable, safe and attractive to consumers, and then get those technologies to market quickly with high quality.

About the author:

Doug Burcicki is the automotive director of the Integrated Electrical Systems Division of Mentor, a Siemens Business, responsible for strategy, execution, and thought leadership. Prior to joining Mentor in early 2018, Burcicki was vice president of Yazaki North America, where he held several management roles during his 24 years of service. He holds a Master’s in Automotive Engineering from Lawrence Tech University and a BSEE from Wayne State University.

Comments