Can modern planes still manage high intensity radiated fields, lightning strikes?

Airplanes are designed to take the jolt of a lightning strike. But changes in material and influx of electronics systems are making the design increasingly complicated.

Once aircraft were built from highly-conductive aluminum, but now the more modern aircraft are designed with less-conductive composites or non-conductive fiberglass. Meanwhile, today’s airplanes are flying super computers with complex electronic systems and integrated communication and power systems.

Boeing recently reported in its AERO magazine that an airplane flies farther than its own length in the time it takes a strike to begin and end. This means that the entry point changes allowing the charge to reattach to other locations aft of the initial strike and can result in multiple burn areas impacting the aircraft’s structural integrity. Indirect effects are particularly dangerous for “safety critical” electronic systems like avionic and engine control equipment.

This alters how engineers, designers and system architects create the aircraft and how they can receive certification by proving its effectiveness in managing electromagnetics.

That’s why it’s critical to address indirect effects of lightning (IEL) issues early in the design process. The earlier these issues are discovered, the more cost- and time-efficient it will be to fix these problems and not hold back its certification process.

Adopting a digital twin with electromagnetic simulation capabilities early in the process helps engineers evaluate these issues and account for indirect effects of lightning in the aircraft design. This can prevent overdesign or inappropriate design of equipment, systems and aircraft protection items. Global aerospace industry manufacturers are increasingly adopting a digital twin approach to reduce expensive and time-consuming late-stage testing by addressing these issues early in the design phase and well before creating a physical prototype.

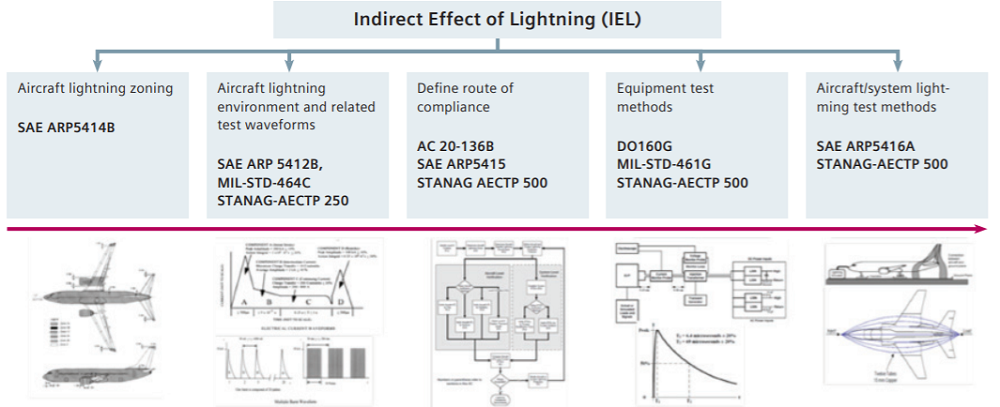

Outside of the design phase, the validated digital twin can be used to effectively manage the certification of updated aircraft configurations. Should lightning strike the aircraft, aerospace manufacturers can demonstrate their aircraft equipment’s ability to continue performing safety-critical functions and maintain its transient current and voltage levels below the qualification values. Figure 1 provides manufacturers with a clear scheme for certifying IEL compliance.

The trouble with radio frequency

Lightning is one extreme form of an electromagnetic threat, however, more commonplace is electromagnetic interference generated from external radio frequency (RF) energy sources, such as from radio, television and radar emitters. As products include more electronics, engineers must understand how external electromagnetic radiation can potentially affect and interfere with the performance of the product they are developing. Electrical motors, sensors and antennas are all examples of common products or components and can benefit from electromagnetic simulation’s role in the development process.

High intensity radiated fields (HIRF), also known as external electromagnetic RF fields, can enter the aircraft structure through specific points of entry such as apertures, gaskets and composite materials with low shielding effectiveness. These fields may couple to cable harnesses or directly interfere with electronic units. Just like when developing for IEL, it’s important to consider the electromagnetic shielding properties of the internal and external structures of the aircraft since from the initial design stages to best demonstrate compliance with the HIRF certification requirements.

Managing complex HIRF and IEL aircraft design and certification with digital twin

Certification authorities have recognized numerical analysis and simulation as an option to support IEL and HIRF compliance. The digital twin process for IEL and HIRF certification compliance starts with a high-fidelity simulation model of the aircraft, known as a digital mock-up. This model is validated by a defined set of physical tests, setting the foundation for the certification phases. Prior to executing and achieving certification, a compliance analysis plan must be prepared and approved by the various certification authorities.

To meet certification, the simulation must be highly accurate and account for any different physical regime dominating the frequency spectrum of interest, such as DC, skin effect and high-frequency scattering. Many physical observables such as electric fields and bundle currents and voltages have to be computed.

Accuracy requires a multi-method approach meaning simulation must be as complete as possible. Modeling the smallest details, such as bonding and grounding contact resistances, apertures, seams and gaskets throughout the entire aircraft structure is critical.

This multiscale problem poses significant requirements for CAD processing capabilities. Just think about the computational challenge of generating and managing meshes composed of millions of elements and managing numerical ill-conditioning. Don’t forget accounting for software and hardware acceleration methods based on iterative solvers, preconditioners and parallel coding.

Therefore, engineers need a simulation suite with advanced and diverse computing capabilities and seamless interaction between CAD and CAE tools for high-fidelity modeling and traceability without losing data intelligence.

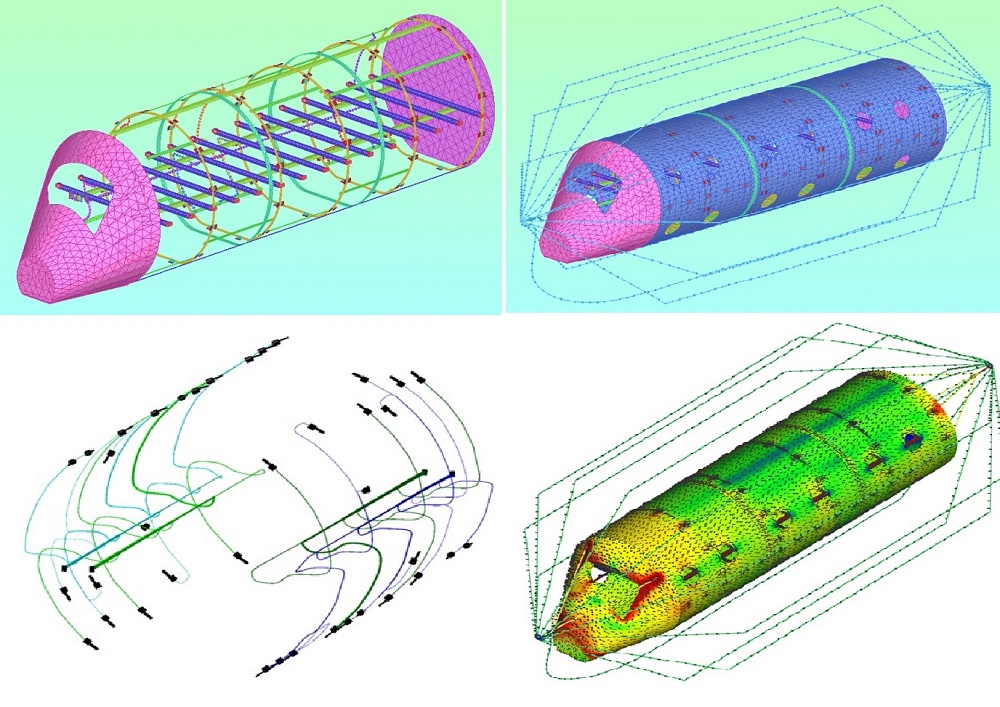

But the challenges don’t stop there. The digital twin needs to automatically import cable harness electrical CAD models, including the harness architectures and 3D routing, bundles composition, cables cross-section, cable jackets and braids, junctions and loading terminations. Then it must translate them into models suitable for hybrid 3D electromagnetic Multiconductor Transmission Line Network simulation (see figure 2).

Considering material modeling based on equivalent parameters, such as shielding effectiveness for penetration problems, surface impedance or transfer impedance for scattering/induced currents problems can reduce the complexity of the model (Figure 3).

Fig. 3: Aircraft fuselage mock-up for validating lightning tools: meshed model, harness and currents (courtesy of SAFRAN-Labinal)

When looking at this example, two key electromagnetic development elements have been addressed: complexity and scalability. By combining various digital and simulation tools and electromagnetic usage levels, designers, engineers and system architects can create a workable and accurate digital twin that seamlessly connects to a PLM backbone.

“Leading companies today realize the value simulation can bring to the product development process in terms of cost, speed, and impact to innovation.” Jan Leuridan, Senior Vice President, Simulation and Test Solutions, Siemens Digital Industries Software.

About the Author:

Mauro Bandinelli received his degree in Electronic Engineering from the University of Florence and the annual Italian Telecom Company award for his thesis work on “Numerical methods for antenna array design” in 1986. Presently he is Director of the ElectroMagnetic Engineering Division in IDS S.p.A (Italy). His professional activity has been focused on different aspects of applied electromagnetism: development of numerical/asymptotic computational methods and CAE tools for electromagnetic modelling, EMC/EMI, system integration, antenna and smart materials design, propagation and scattering.