Why you should 3D print a rocket

3D printing is an amazingly versatile method for manufacturing, it can create forms impossible with other techniques and forgoes the expensive tooling development. It can consolidate entire systems into single components and create additional structures to improve the performance of existing components. But with all my bets on the future of additive manufacturing (AM) as a transformational technology, printing an entire rocket was nowhere in the calculation. The scale and complexity seemed too much, but there are others that saw past the logistical problems to the benefits of the application of AM.

For a great overview of the project, Derek Muller of Veritasium has a great video interviewing Relativity Space and explaining some of the background on why they are implementing AM for their rockets. But generalizing Relativity Space’s use of 3D printing, how will it impact the wider world of aerospace and even all of manufacturing?

Accelerated design cycles

The first improvement to aerospace manufacturing is not strictly through the use of AM, but is instead a follow on effect from the technology compared to traditional techniques for manufacturing. Traditionally, the high customization and low volume of rockets being built meant that each one was built by hand. Investing in mass production processes didn’t make sense because the investment was far to high for a product that would maybe see a few dozen units before it was replaced with a better technology. Additive does not require that upfront investment in tooling or molds and it removes much of the time associated with hand-built rockets. The combination of these two evolutions means rocket engineers can iterate on their designs very rapidly, improvements to the design do not have to wait for the next generation of rocket, only the next launch.

Weight savings

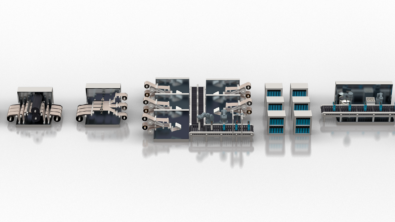

Just like every other application of AM, there is the benefit of weight savings. The impact is far greater for rockets and space shuttles however because fighting gravity and drag is a much more intensive task than just overcoming drag. Weight savings are achieved in a variety of ways by implementing AM, by consolidating components weight can be minimized by removing the connections previously required to assemble the system. Optimizing structural mass is the other major option for shedding weight, by creating internal lattices or removing sections of material that remained from traditional manufacturing methods, but did not contribute to the overall rigidity of the systems.

Performance improvements

Performance is the last major prong of AM’s benefit for rocket design and can also be achieved in a variety of ways, with the first already being touched on in reference to weight saving – component consolidation. By turning a system of components into a single component, the function can be even more optimized to say improve the pressure drop in a fluid system or provide superior mixing properties in a rocket thruster for peak performance. Secondary structures can also be added to components, whether internal or external to increase performance – conformal cooling moves heat removal into the part for better thermal efficiency and ribs can be added to a thruster cone to provide much greater strength with less material.

An evolving technology

The scope of viable uses for additive manufacturing is expanding every day with improvements to technology, software and maybe most importantly the ingenuity of the users. AM started as a way for designers to get mock-ups and prototypes faster, but now the technology is being used to make custom components optimized for performance and even entire rockets. I am genuinely curious where the technology will go next. Wherever it is Siemens Software is going along for the ride and creating the tools to make the future a reality.

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – Where today meets tomorrow