3D printing for nuclear energy

With the relatively low coverage on the nuclear energy industry, many likely sit in two camps – either nothing has changed since the first energy facilities in the 1950s and 60s or the highly optimistic looking at the emergence of fusion reactors. Honestly, neither evaluation is very accurate leading to limited understanding of the current state of affairs unless you are in the industry. There are modular designs that harness the efficiency of scalable manufacturing receiving licenses, and operating reactors have been reengineered to extend their usable life and even increase power capacity safely. But there are also innovations happening in the research and university settings to make nuclear energy production a viable choice for our energy markets. One such technology is 3D printing components for nuclear reactors.

Developed at Oak Ridge National Laboratory (ORNL) in Tennessee with funding for the Department of Energy, a novel method for printing nuclear reactor components is being licensed private firms for their designs. For similar reasons as one might find in other industries, components are becoming ever-more complex to meet efficiency and performance requirements. For nuclear applications however the complex does not rely solely in the geometry of the components, but the overlap of the material and the geometry. New generations of reactors are integrating more sophisticated refraction elements to sustain the nuclear reaction for effectively.

If you have not had any education on nuclear physics, let me explain. A nuclear reaction is the splitting of an atom, uranium or other unstable and heavy elements. This happens by hitting the atom with another particle, most commonly a neutron. On collision, the atom splits into roughly equal halves. At separation, more neutrons are released and collide with more atoms. With the right environment this can happen indefinitely and is controlled by reducing how many free neutrons are moving through the reactor. Reflectors or refraction surfaces push the neutron back towards the center from the edges to multiply the neutron population, while control rods absorb the neutrons reducing reactivity.

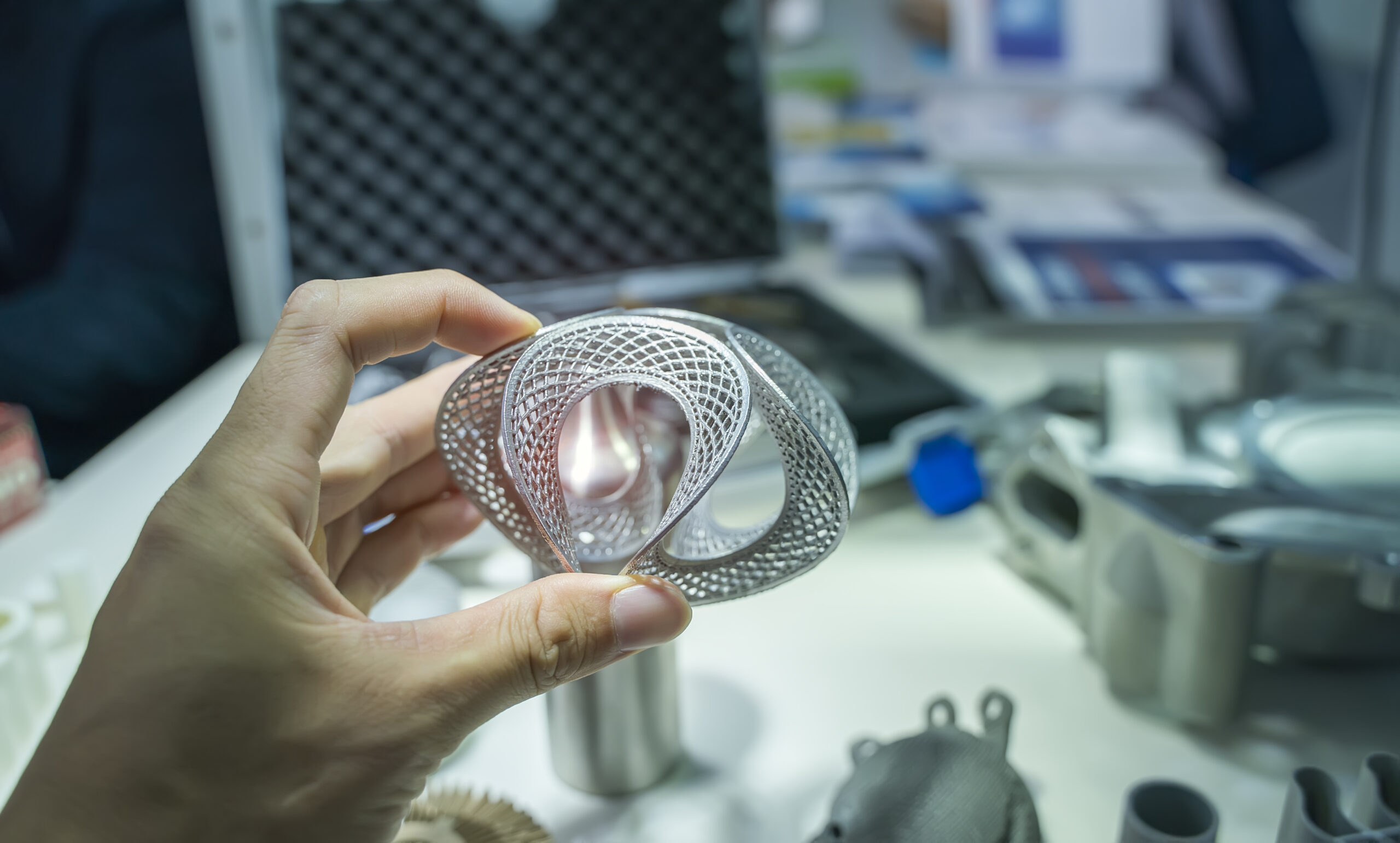

These reflectors sustain very harsh environments from the nuclear reaction, from collision and the heat generated by splitting atoms. To combat the environment silicon carbide is the material of choice for most designs – it is highly heat resistant and fairs well against nuclear decay fragments (radiation). Unfortunately these properties which make it a great choice also make the material very hard to machine with traditional methods. This is a challenge in completing the nuclear reactors of the future and it is where ORNL’s work comes into the spotlight.

Through a binder jetting print process to layer the ceramic material and a chemical vapor post processing step, new highly complex geometries can be created. These geometries can include surface textures or patterns to optimize the refection of neutrons in the reactor or create conformal cooling channels like those found in other industries to improve performance. Even more importantly, perhaps, are the applications away from the reactor core where all of the heat is being produced. Where does all this heat go after being transmuted from chemical potential energy?

The heat exchanger. The working fluid, water in most cases, moves up through the reactor as it is heated and moves through the exchanger where the irradiated fluid transfers heat energy through a boundary layer and into a separate loop of water with connects the steam loop and eventual the turbine producing electricity. The complex geometries possible with 3D printing can make this transfer of energy even more efficient by maximizing the surface area within the heat exchanger and increasing conduction.

Innovations like this may not ever been seen by the majority of people, even those within the energy industry aside from a bump in plant efficiency, but it does not discount the amazing work being done in the background. 3D printing has amazing potential, even if it is not in printing custom products for individual consumers. If you are interested in learning more about this advancement from ORNL, please check out the news listing on their website. I hope to be able to tell more stories like this while we collectively figure out how our future energy market will look.