What is continuous verification for MBSE?

The newest goal of product design and development has become failing as fast as possible. Not is the sense that a project is dead, but as a means to find the problems in a design as fast as possible. When a product includes interconnection between mechanics, electronics, and software there are many avenues of failure in the field if it is not qualified effectively in development. But failure is only helpful if the decisions leading to it were tracked and are changed, this workflow is continuous verification. In the sixth episode of Model Based Matters, Tim and I talk with two controls systems experts – Jan Richter and Michael Baloh of Siemens – to explain why failures are such a valuable tool for development, how models are entering the workflow earlier than ever, and what role continuous verification plays in understanding a system.

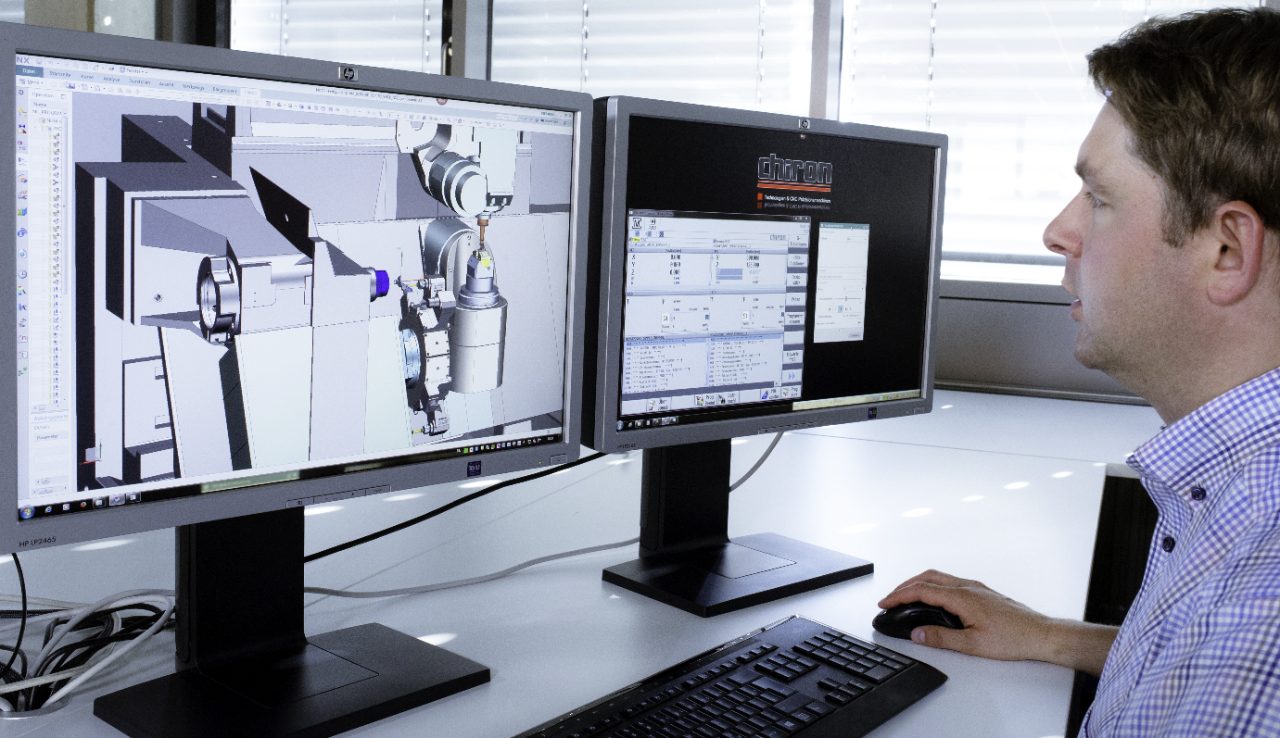

In continuous verification, the model of model-based systems engineering or MBSE is arguably the most important aspect of the process. It is the analog for the real world created in the virtual world, enabling engineers, designers, and others to work without hesitancy. Developing a product in the digital creates a low-stakes environment where the best ideas can flourish, and the worst can be uncovered for what they are. And all of this is possible because of the many models available early on in the development process.

There are the eponymous system models which often convey the requirements of a product as 1D representations with call-outs for specific system requirements. These provide a high-level understanding of a project to make the early decisions of development. They can take the form of business assessments to understand the cost benefit of specific development paths over another, but these early models can also contain physical descriptions if the system being designed is an iteration of a previous design. Continuous verification ensures the decisions made in this phase of development adhere to the definitions of the product and as the designs are refined in the relevant domains the models will be continuously evaluated to stay on track.

Simulation is another wealth of information to the continuous verification process in MBSE, it is the physics of this digital world for the development teams. Rather than manufacturing a component to test it in the physical word, it can be designed in the digital and tested there with simulation – be it computational fluid dynamics (CFD), fatigue simulations, or even simulating an entire vehicle on a virtual test track to understand vehicle dynamics. Whatever the test, the results are added to the catalogue of information in a single source of truth, the digital twin of your product. By making this data interrogatable and executable to everyone, alterations can be made easily and earlier in development leading to a better product being delivered faster.

The last major model type we talked about for continuous verification and MBSE was testing and how it creates a bridge between the virtual and the physical domains. The discussion was very insightful, but we had to save it for a second episode because we ran out of time. Luckily if you are reading this summary of episode six, you only have a day to wait before the second half of our discussion goes live on the Model Based Matters podcast.

And if you are confused why I’m only talking about continuous verification, and not validation, analysis, testing, or any of the other forms of interrogating a system, I’d recommend listening just after minute 13. While we talk about many of these topics interchangeably, they are unique and have very distinct benefits to development, but naming all of them within continuous verification becomes very tedious. Other than that, I hope you find this episode as interesting as I did while having it and if you are more interested in the convergence of the physical and simulated, I highly recommend the following episode on testing practices. Now get out there and fail safely to make the perfect product faster!

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – Where today meets tomorrow