Sustainable additive manufacturing with the AMGTA

Additive manufacturing (AM) and 3D printing are amazing tools for making the most efficient parts for a product, through light weighting, improved cooling paths, better aerodynamics, and a variety of other techniques. But for a sustainable process, making the part more performant is only half of the equation. Making the component also has to be efficient. The Additive Manufacturing Green Trade Association (AMGTA) is working to define the variables of the sustainability equation through partnerships with research institutions and companies in the industry. And in highlighting the work being done to make our world more sustainable, their Executive Director Sherry Handel is interviewing association members to get their perspective on the industry. The second spotlight was with our resident AM expert Ashley Eckhoff, let’s see what he had to say on sustainability in the industry.

Benefits of membership:

Aside from being a good corporate citizen and steward of the planet, being a member of the AMGTA provides technological understanding of the practices we facilitate for sustainable applications. It can be easy to assume a process or practice is environmentally friendly or valuable to a customer, but the work the AMGTA provides on clarifying those statements is highly valuable. They provide independent insight into how software, hardware and materials technologies impact our planet.

Sustainability challenges in AM:

The greatest hurdle to understanding impact is the scope of any project, making a measurable impact requires addressing problems on multiple fronts at once. Does material choice enable progress towards circular economies? Can software optimize for minimal material usage? Can the hardware systems be driven as efficiently as possible? All of these must be solved in tandem because focusing on a single avenue could result in inefficiencies elsewhere. AMGTA is a great resource in understanding the weighting of these problems, enabling us at Siemens to make the entire process sustainable for customers.

Widespread sustainability:

In addition to partnering with organizations like the AMGTA, Siemens conducts first-hand outreach on environmental topics in industries all around the world. It also provides the unique ability to combine and filter information as we interact with our customers on what sustainability means for them. This is evident in the consumer products industry because of the more frequent interaction between the public and corporations, but we also work with manufacturing companies, farming groups and the supply chains of industry.

For AM, it is important to look at manufacturing as a part of a wider process where efficiencies can feed into and out of manufacturing based on the decisions. Logistics, traceability and decarbonization will be important topics around manufacturing to reduce environmental impact as much as possible. But getting there will take personal commitment from corporations and the public, consumer products is the easiest starting point and will likely act as a proof for other industries.

The digital twin:

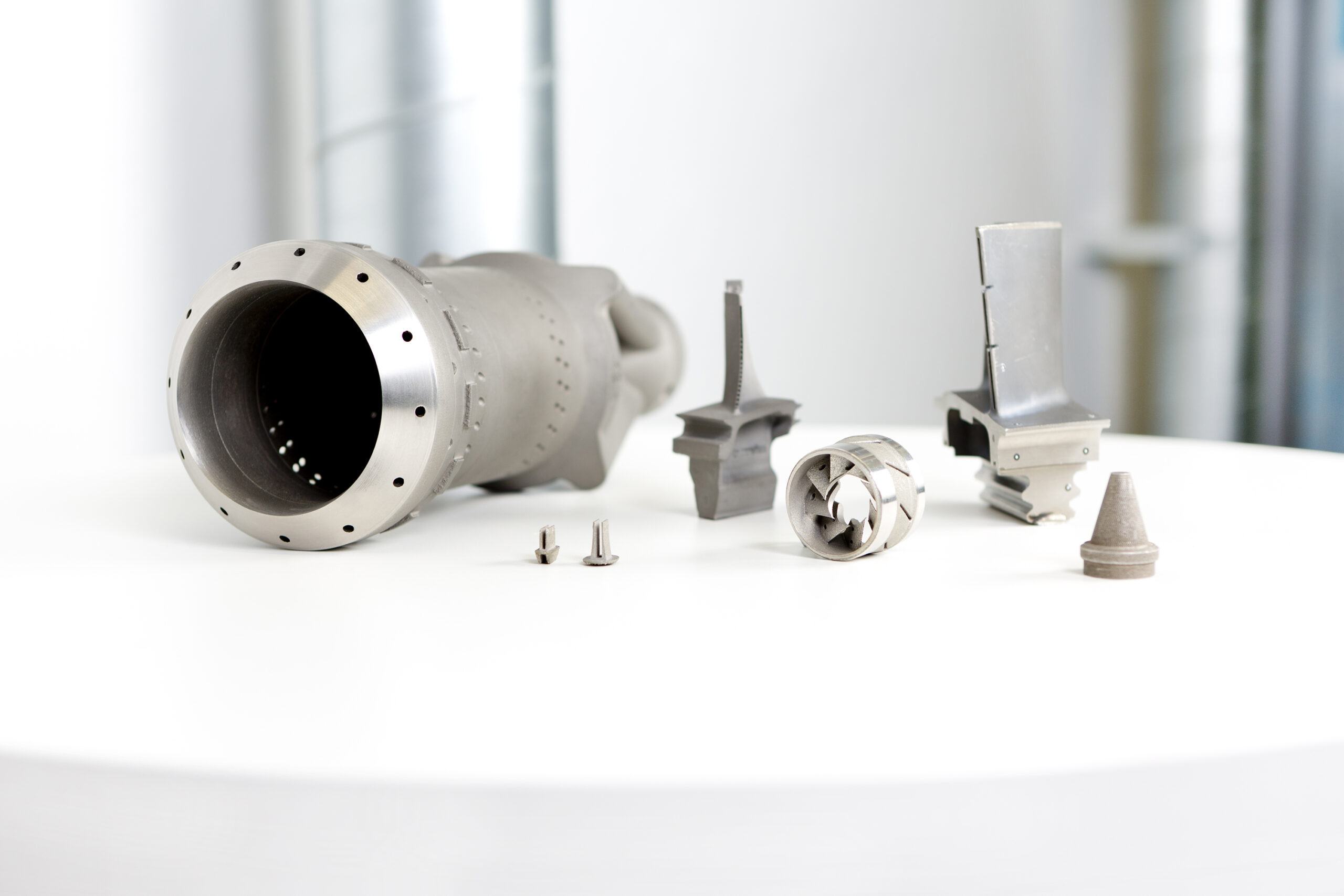

The digital twin is the collection of computer data constituting the product and associated processes to development. For additive this includes the data describing the geometry and material of a component, along with the process information needed for manufacture by the employees and machines. The digital twin enables an understanding of the part’s manufacturing process before it is printed, enabling refinement without wasted material or energy. But a digital representation also provides a simulation environment to improve the performance of a part, for applications in aerospace and automotive an improvement to aerodynamic efficiency or part weight has a direct impact on energy consumption.

For more information on sustainability in AM, I’d highly recommend reading the full interview in the AMGTA Spotlight or checking out the work the AMGTA has been doing in the industry. But you might also what to check out Siemen’s commitments to creating a more sustainable world through our DEGREE framework. And in the longer term, some great research data will be coming out from the AMGTA and their research partners on how to make additive manufacturing a sustainable option for manufacturing today.

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram. Siemens Digital Industries Software – Where today meets tomorrow