Cloud-based Advanced Machine Engineering is digitalizing next generation machines

In an engineering.com article, Rahul Garg, VP for Industrial Machinery & SMB Programs at Siemens Digital Industries Software, discusses the rise of emerging geopolitical issues that impacts IT infrastructure simplification and technology, driving machine manufacturers to build smarter machines to address global competition, challenging supply chains, shrinking margins and growing energy, environmental and government regulatory requirements.

Simultaneously, consumer preferences are constantly changing, driving product manufacturers to desire agile, flexible machines that create many products. Therefore, machine builders must engineer machines that integrate hardware, software, and services within a collaborative environment.

“Through these integrated tools, machine builders can incorporate greater automation and integrated quality into their products—driving greater efficiency into their processes while helping to differentiate themselves from other market players competitively. But, of course, that requires smarter software solutions to support machine design and manufacturing,” says Rahul Garg

Advanced Machine Engineering (AME) is rising as a digital method that drives certainty in creating next-generation machines.

“It delivers a cloud-based, digital thread approach that empowers companies to develop increasingly complex machines faster, lowering development costs and leads to decreased production and operational costs,” says Garg.

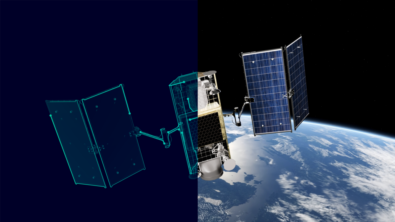

AME joins the digital twin’s development with the mechanical, electrical, electronics and software engineering disciplines all collaborating into a single source of truth—breaking down engineering silos and streamlining the communications essential for designing advanced machines. The result is companies can better manage their projects, employing complexity to deliver lucrative machines, gaining a competitive advantage.

Project management optimized in the cloud

The cloud is essential for the full potential of AME, assisting teams to build smarter machines more rapidly. Using the cloud galvanizes collaboration that helps support multiple engineering disciplines.

“Cloud-based solutions allow the mechanical, electrical, automation and software disciplines to amalgamate under one integrated space. The cloud is easily accessible to all and provides visibility into each discipline’s work stream, maximizes data reuse, supports an integrated change process and can ensure a standard delivery process while quickly adapting to evolving best practices,” says Rahul.

Cloud-based collaboration allows physical and remote employees to work under an integrated platform. When you align all the workers in the cloud, engineering teams can store, access, and utilize real-time dashboards, schedules and documents anytime and anywhere, thus driving efficiency into the machine development processes to improve productivity.

Then organizations can see how a project progresses while gaining better traceability. Project data can be found, shared, and scaled throughout the organization, promoting better remote collaboration. At the same time, machine builders capture and incorporate design feedback from several stakeholders to create the most effective machines without delays or high costs. Machine builders can also address supply chain issues and source materials vendors when they include input early in the design process.

Connected engineering in the cloud

A digital twin can provide a multi-disciplinary model of a machine, collaborating with the mechanical, electrical and automation engineers to evaluate the performance, energy use, output and essential indicators that enable multiple disciplines to work cohesively.

Then, closed-loop testing enhances the analysis to produce flexible and optimized machines that enable you to control the engineering data from all disciplines in one change process. The benefits of using the digital twin are known by using cloud-based technology, merging the engineering disciplines online and offline and combining their input and data.

Learn more in the article.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.