Industry Outlook 2024: The renaissance of smart machines for the factory of the future

In a recent article in The Manufacturer, Rahul Garg, Vice President for Industrial Machinery and SMB at Siemens Digital Industries Software, discusses how machine manufacturers face volatile market environments, driving them to adopt new approaches for developing next-generation products.

In 2024, manufacturers face ever-present quality, cost, and performance demands. Furthermore, sustainability requirements are prominent, focusing on lowering energy usage with less carbon while minimizing scrap and waste.

Global trends impacting industrial machinery industry

Additionally, trends impact manufacturers globally, while social-political shifts lead to business model changes like reshoring, servitization and new market entrants. With these variables come new emerging areas, moving from well-established domains into adjacent or new markets.

A prime example is paper machine manufacturers moving into battery machine manufacturing to address the increasing demand for electric vehicles. This also holds true for the glass manufacturing industry. Also, workforce shortages in machine builders and manufacturing operations drive more automation. Therefore, the future factory is developing paradigms of sustainability, flexibility, and the future workforce.

Digitalization in 2024

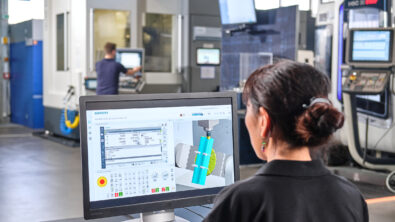

Technological advancements allow manufacturers to thrive despite many challenges in the industry. And new capabilities make it possible to have greater intelligence and data wealth generated by digitalization. Then, this integrates digital tools, systems, and IoT data to connect siloed information across design, engineering, production, and service.

Digitalization allows manufacturers to move beyond automation to be predictive and adaptive to production environments. Adaptive manufacturing delivers the flexibility to enable painless production switching with changing markets and customer needs. Also, it streamlines the workflow systems, allowing manufacturers to accomplish more with the same workforce.

Digitalization lowers manufacturing risk by furthering flexible processes and accessing crucial data across engineering and production disciplines. It weaves the data from the once-siloed disciplines, requiring solutions built on an in-depth understanding of machine design, simulation, factory automation and project lifecycle management (PLM).

Learn more in Rahul’s article.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.