The future of smart machines and smart industries – ep. 3

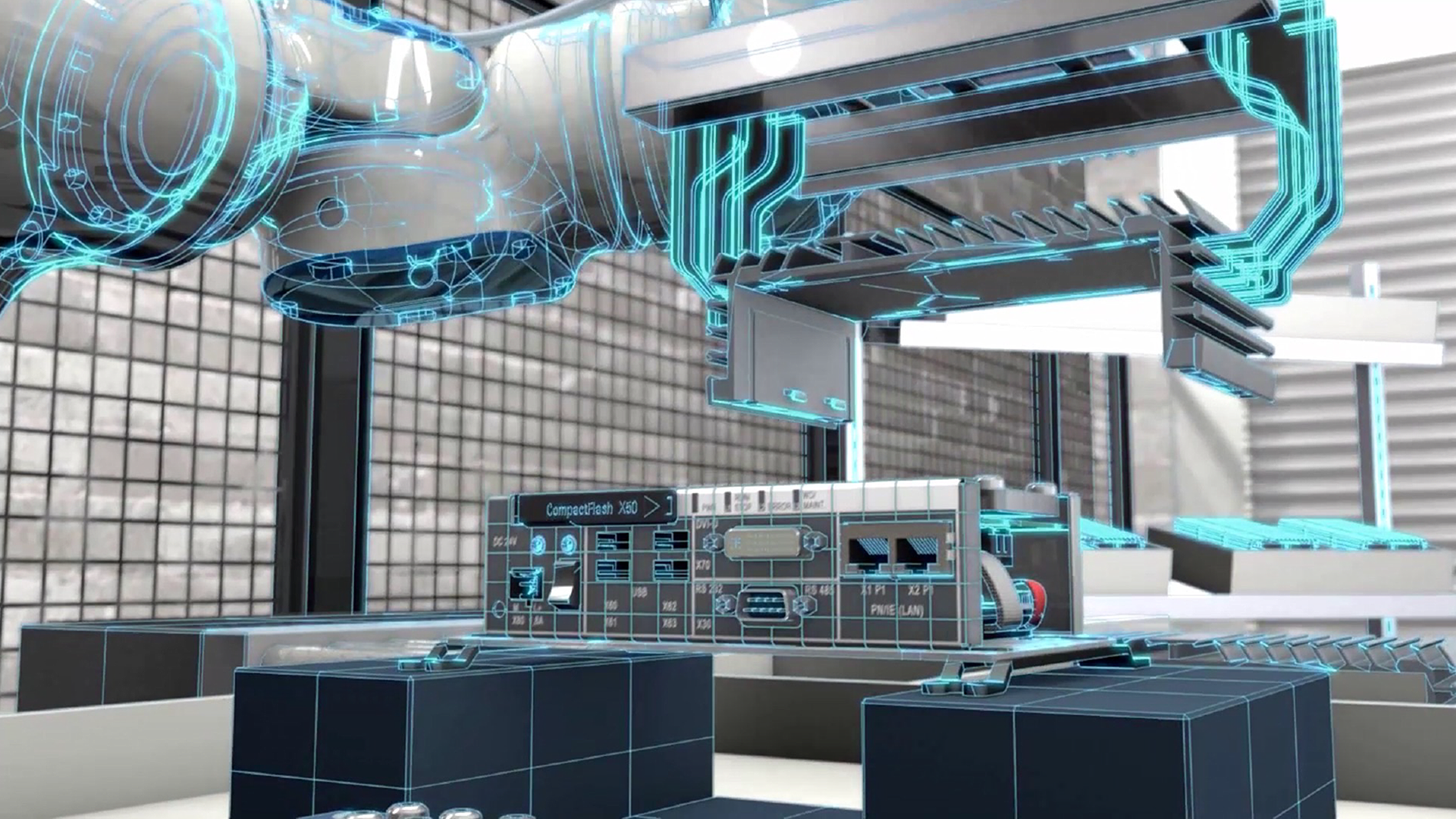

In part three of our smart machines/smart industries podcast series, we are once again joined by our engineering experts, Dale Tutt, VP of Industry Strategy; Rahul Garg, VP of Industrial Machinery; and Michael Thomas, SVP of Digital Industries Factory Automation and Head of Production Machines at Siemens Digital Industries Software, where they discuss the trends and challenges in the manufacturing ecosystem today, including technological advances on the horizon, and the role of digitalization in enabling the future of smart manufacturing.

In this podcast, these industry leaders provide an in-depth look at the transformative intersection of software and automation within the manufacturing landscape. They cover:

- The advantages of partnering with an industrial automation and software company

- How an integrated automation and software offering can help shorten time-to-value

- How cloud-based offerings can help manufacturers remain flexible to future disruptions and demands.

Their insights demonstrate how Siemens’ blend of expertise, global reach and innovative integrations are propelling businesses towards manufacturing excellence.

The value of an integrated automation and software offering

The integration of automation and software solutions plays a pivotal role in accelerating time-to-value for manufacturers. By streamlining processes, reducing complexities and offering seamless compatibility, integrated solutions enable swift implementation, which is essential for businesses dealing with global challenges like workforce shortages and increased product complexity.

Siemens Digital Industries (DI) is uniquely positioned as a vendor with expertise in automation, software, PLM process and domains. This multi-level proficiency enables Siemens to understand the challenges of design and validation rules, making them an ideal partner for machine builders.

In addition, Siemens provides:

- Unparalleled global presence: Siemens international footprint provides essential support to machine builders worldwide.

- Integrations for efficiency: Virtual commissioning capabilities, real-time monitoring and Edge device integration offer manufacturers streamlined solutions to optimize operations.

- An open ecosystem and cloud-based solutions: Siemens fosters an ecosystem, making it easier for elements from different sources to come together. Additionally, as the technological landscape shifts towards cloud-based solutions, Siemens ensures compatibility for companies of all sizes. Whether a small enterprise, mid-size operation or large OEM, the technology is within reach.

- Customer-centric approach: Because no two operations are identical, Siemens underscores the importance of tailoring solutions to individual customers and guides them on their implementation and transformation journeys over the long term.

This holistic strategy distinguishes Siemens DI apart from other vendors who can only offer individual components to manufacturers looking for integrated automation and software solutions.

Preparing for future success

For manufacturers hoping to overcome challenges and thrive in an evolving landscape of smart manufacturing, they must embrace digital transformation. The key to attaining their business objectives lies in leveraging digital tools and digitalization.

Digital transformation empowers machine builders to integrate new technologies like IT/OT convergence, artificial intelligence (AI) and machine learning (ML) into their operations. By automating tasks that were once manual, businesses can operate at a faster pace and achieve greater efficiency, even in the face of labor shortages.

Above all, Siemens DI is committed to being a trusted partner for customers. Through an open ecosystem, deep knowledge across industries and the ability to provide integrated automation and software solutions, Siemens DI stands ready to support businesses in their digital transformation journeys.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.

For more information on Siemens Digital Industries Software products and services, follow us on LinkedIn, Twitter, Facebook and Instagram.