Shop floor role model

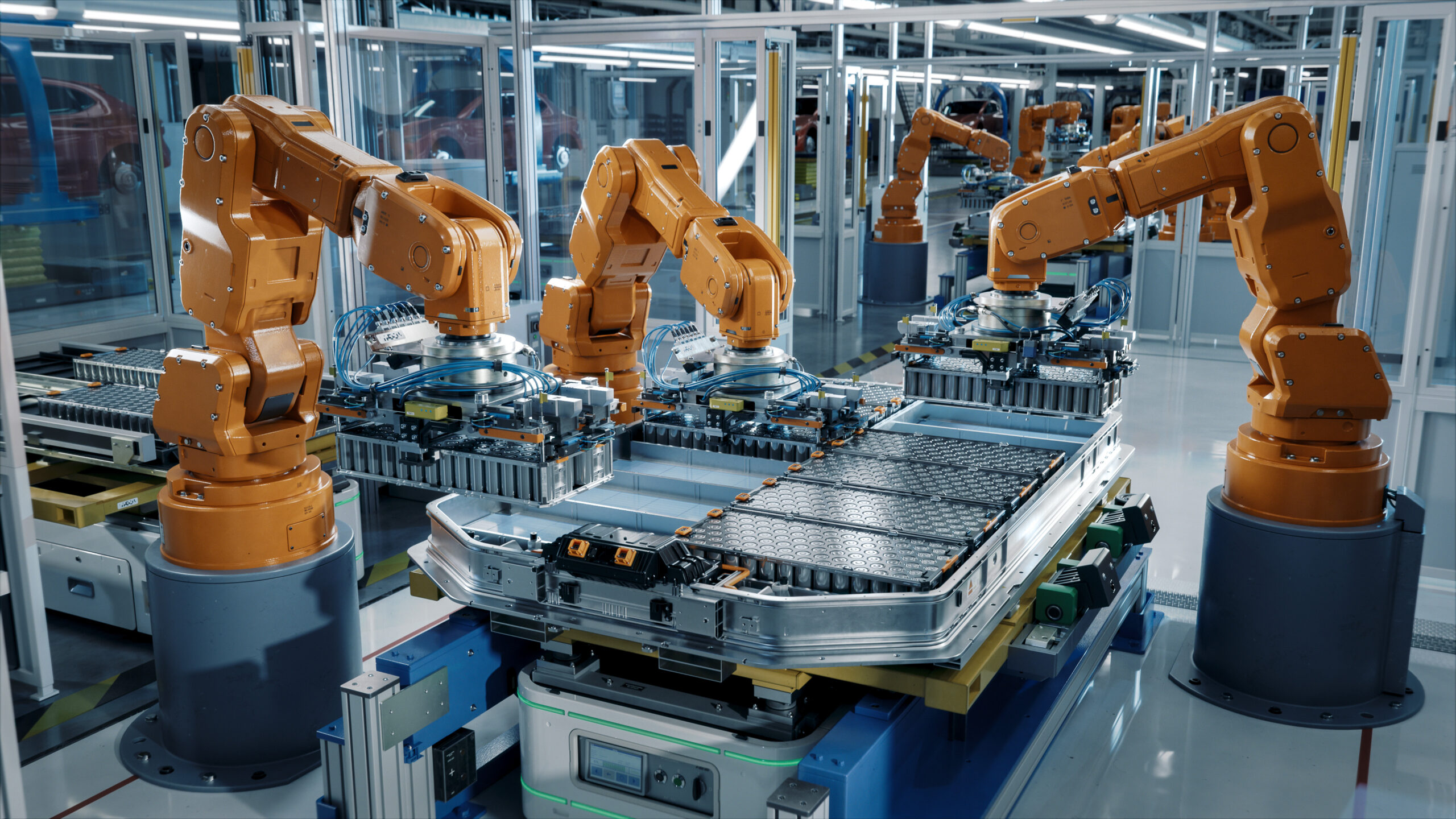

As industrial manufacturers strive to cut costs, enhance production lines, and make operations more sustainable, they have begun to embrace digital transformation —and IT/OT convergence is a key player in this transformation IT/OT convergence enables factories to identify areas of improvement on the shop floor using data and deploy operational solutions to address pervasive issues including skilled labor shortages and rising production costs.

The benefits of digitalization are real. In fact, Siemens’ electronics factory in Erlangen, Germany has successfully actualized the advantages of IT/OT convergence by taking advantage of Siemens’ own solutions. By digitally transforming its PCB assembly production they have been rewarded with considerable and continued benefits, solidifying themselves as a blueprint for manufacturers.

Setting expectations as Customer Zero

The factory at Erlangen had to contend with its many legacy plants which operated a diverse pool of machinery. As well, each plant utilized separate interfaces and generated many types of data in incompatible file formats. To address these issues, Erlangen’s development team worked closely with our own solutions to provide purposeful feedback and test products.

Leveraging Industrial Edge, the factory began to homogenize shop floor data, generating insights into production lines and systems. Mendix on the Industrial Edge allowed Erlangen to analyze each plant’s log files, determine their operational status, and transmit the data to its database for easy visualization on a dashboard which made the data available to its entire workforce.

Sipping on the benefits

By drinking their own champagne through the use of Siemens solutions to connect their shop floor, Erlangen freed previously inaccessible data, enabling it to utilize automated AI insights coupled with employee experience to better identify the most critical production line issues. This enabled them to acknowledge significant bottlenecks in their processes. This led to 4% improvement in productivity and a 60% reduction in employee workloads. Additionally, Industrial Edge’s AI offerings improved preventive maintenance, detecting up to 60% of pseudo faults on the shop floor.

These aren’t the only gains the factory saw from IT/OT convergence. Mendix facilitated data-based decision making, allowing Erlangen to dynamically control production processes before making physical changes to the shop floor. This ultimately accelerates the factory’s innovation process, helping them stay ahead of rising costs.

With IT/OT integration Erlangen is also tracking fluid and consumption rates as well as energy consumption. The increased transparency of their production’s environmental footprint enables them to derive machining processes optimized for sustainability. Striving to continuously adapt, Erlangen uses its data to find new methods to eventually eliminate failures and create a closed-loop system.

Approaching the future and beyond

Integrating our own Siemen’s solutions pushed our Erlangen factory to pursue IT/OT convergence and begin tackling industry challenges. Moreover, diligent testing and feedback bolstered the success of the factory’s digital transformation. Through Industrial Edge’s various capabilities, Erlangen could consolidate their systems and harmonize their data, address sustainability, and bolster innovation. Additionally working with homegrown platforms helped the factory eliminate production bottlenecks and enhance data management, allowing them to cut testing times and expenses.

The future is bright for the Erlangen factory. The factory’s leaders and innovators see their digital transformation as an intermediary step towards the industrial metaverse–a virtual space that expands on the physical world which fosters efficiency, productivity, sustainability, and connectivity. IT/OT convergence platforms like Industrial Edge enable employees to access data quickly and easily. This is a crucial step towards creating smarter factories, improving the sustainability operations, and ultimately revolutionizing the manufacturing landscape.

To learn more about how Siemens Electronics Factory Erlangen, Germany combined state-of-the art production methods with the latest technologies such as digital twins, AI, and IT/OT convergence here.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.