How can you reduce failure and minimize product cost?

Inaccuracies in product cost estimations and the lack of technology to correct it hurts companies that continue to develop and produce new products. Product costs that cannot be recuperated, and an inability to verify and test products, can be detrimental to businesses and reduce their competitiveness.

In our look at challenges with new product development, our first blog focused on why this development fails up to 80 percent of the time and identified challenges that have significant, negative impact on the success of new product development and introduction (NPDI). In our second blog, we’ve addressed three challenges and the means to solving them.

Now, we will examine two other challenges in more detail and how companies can counter them.

4. Inaccurate cost estimations

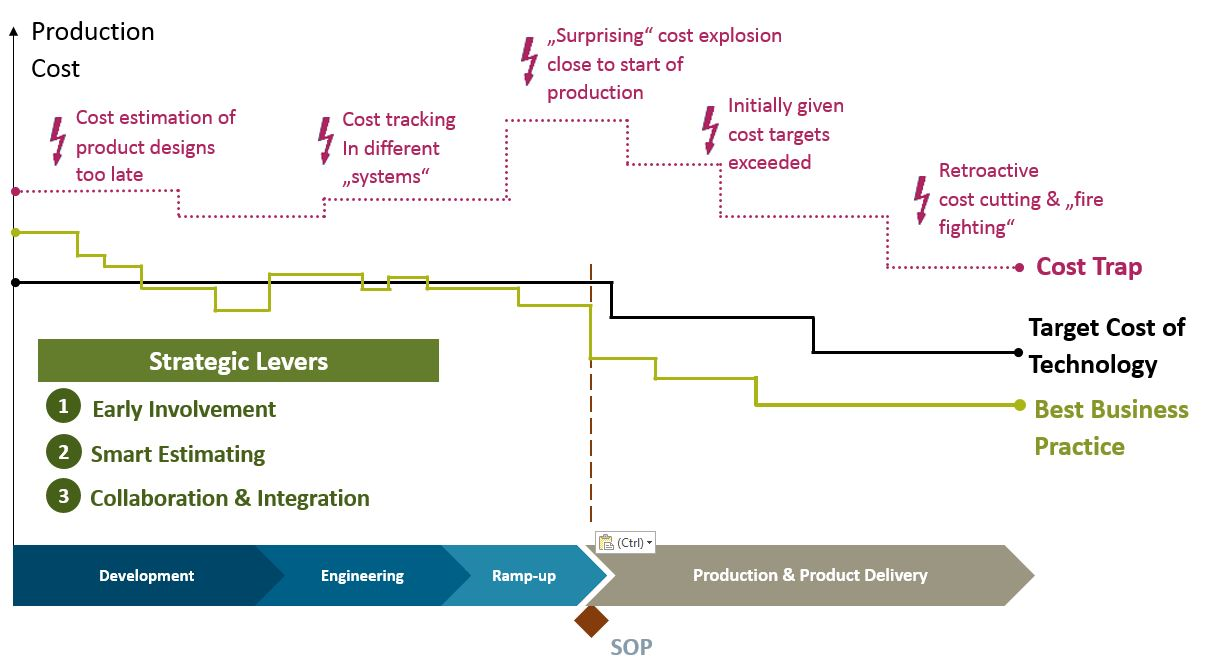

The Problem. Analysts have pointed cost as the main risk factor in NPDI. Despite this, many companies do not have a robust way to predict costs.

Historically, the Excel sheet or spreadsheet used during the new product development process often focuses costing around individual departments. For example, labour rates may be used as a driver without considering machine cost and depreciation, or part price without its landing costs, including shipping & handling.

However, according to a paper published in the Journal of Corporate Accounting and Finance, considering only one or two cost drivers out of many can “lead to highly distorted product costs.”

Furthermore, these traditional methods of estimation are usually only available once the design has matured, at which point it is either too costly or too late to change direction.

The Solution. Further research conducted by the Aberdeen Group shows us that a more holistic approach to cost management, such as integrating a cost management tool that spans the boundaries of different business units, has been an effective method in cost estimation.

For example, take an automotive part. A cost management tool, as opposed to a static spreadsheet, can help make decisions on manufacturing techniques using variables such as:

• Part quantity;

• Varying metal prices;

• A business’s accessibility to technology;

• Manufacturing methods; and,

• The costs of manufacturing the automotive part in different countries, which include overseas shipping costs and labour rates.

In addition, including cost intelligence at every stage in the product lifecycle – beginning at the early design and concept stages – can ensure stakeholders are aware of the cost implications of the decisions they make.

5. A lack of simulation

The Problem. In any manufacturing operation, the first prototypes are always the most expensive due to tooling, labour and materials. Test and redesign are some of the most expensive and labour intensive aspects to a new product introduction.

Frustratingly, however, we know that the more prototypes are made and tested, the higher the probabilistic success of that product. While we cannot remove the need for prototypes all together, simulation and digital prototyping can significantly reduce the amount of physical prototypes needed in the NPDI cycle.

This is not new knowledge, however. The advantages of digital simulation are well documented by software vendors, customers and in journal articles such as Sandberg et al 2012, Tena & Clara 2015 and Peltier 2005. In fact, if you’re reading this article because you are in new product introduction, chances are you’re already using or have access to digital simulation tools.

Unfortunately, even when NPDI teams have access to simulation tools, the main issue is there is simply is not enough time in the process to carry out multiple iterations. Firms often employ more designers than simulation analysts so when designs finally get simulated, there is often an iterative process back to the designers to make the appropriate changes based on the simulation results. This process repeats, and time keeps marching onward, increasing time-to-market.

Lastly, many companies struggle to simulate across different physics, fluid, impact and chemical models. A simple example would be a soft drink bottle being tested when dropped. Manufacturers want to test the structure and degradation of the bottle hitting the floor, the mix of chemicals within the bottle after such force and the fluid momentum during the impact. Complex simulations must be completed, but most companies lack the capability to test all simulation models at once.

Simulation of a soft drink bottle hitting the floor is considerably less involved than a simulated vehicle crash involving smashing cars with sensors into walls and the impact of gas and electricity’s ability to cause an explosion.

The Solution. Advances in the use of neural networks in the past two years have significantly accelerated the process to overcome these challenges. Rule-based AI design tools allow automation of the iterative simulation process, allowing companies to squeeze over 200 times more iteration simulations into the same time-frame as they would do two-three iterations before.

Expanding and developing multiphysics simulation — such as mechanical, fluid, airflow, thermal, or chemical — can provide NPDI teams with a single source of the truth. The effect of multiple physics models simultaneously interacting with the product can be measured against each other.

These methods increase speed-to-market by allowing multiple NPDI stakeholders to have access to basic and intermediate simulation modelling so everyone can analyse the impact of their decisions and remove costly bottlenecks.

Final thoughts

We’ve touched on the five main challenges faced by modern NPDI teams and how ignoring the digital capabilities may hinder their ability to launch a successful, cost-effective product.

Companies eager to remain competitive and make use of the technology will recognize the solutions of these five challenges and refine their ability to increase efficiency during NPDI.

This concludes our series about common challenges with new product development and introduction.

About the author

Everything I do is for the sake of my children’s children. I want them to enjoy the things that we take for granted, but I feel we need to make significant changes to the way we consume and manufacture products. This motivation drives both my personal and professional worlds. I believe Industry 4.0 and digitalisation allows for a significant step change in wastage in manufacturing. I think Dr. Seuss said it best, “Unless someone like you cares a whole awful lot, nothing is going to get better. It’s not.”