Video: Industry 4.0 and the Digital Enterprise

Digitalization is a process that can give companies the means to realize innovation faster than their competition. When fully implemented, digitalization can help companies future-proof their business and be ready to compete in a market that can quickly change.

The majority of U.S. manufacturers know they need to digitalize their business, yet we see few taking action; they’re afraid of the unknown. But companies that fail to digitalize their business could face disastrous consequences. We only need to look at what happened in previous Industrial Revolutions to see how quickly the stragglers disappear from the market, and these disappearances will happen even faster in Industry 4.0.

It isn’t too late for companies to incorporate digitalization into their business processes — but they must begin immediately so they don’t become a footnote. And they won’t be alone in their journeys. Siemens is well aware of what the process entails because the company continues on its own digitalization journey so it can survive and thrive in an Industry 4.0 world.

In this video, Alastair Orchard, the vice president of the Digital Enterprise Project and one of our Thought Leaders, explores how companies can learn from history to create a successful future in Industry 4.0 and why now is the time to embrace a digital enterprise.

(The transcript can be found below.)

Transcript: Industry 4.0 and the Digital Enterprise

Good morning.

So by now, you‘ll all have heard of digitalization and the way that companies transform their businesses by fully integrating digital technology into all business processes.

Now, digitalizing a business does much more than just putting paper on glass. It weaves a digital thread through the whole value-chain, giving companies the means to realize innovation much faster than their competition and to future-proof their businesses in a constantly changing marketplace.

But the disruptive nature of digitalization brings with it as much potential pain for manufacturers that ignore it as it does for opportunity for those that embrace it.

You know, entire markets can really disappear overnight with a single innovation. The classic example here was the rapid shift from film-based to digital photography driven by an improvement in technology.

But actually, the adoption of phone-based cameras was far more dramatic, and this was because of the paradigm shift that came with using phones. Whereas you used to take photos to preserve your own memories, you now take them to share with friends and family.

And as digitalization enters the industrial world, we’re certain that if our customers don’t act, then they may also disappear.

Now, it’s a bold statement. But we feel confident about our message because we can go back in history, we can look at what happened during the previous Industrial Revolutions and we can put what we’re doing today in a bigger context.

Now, we had virtually no progress in human life between the end of the Roman Empire and the late Middle Ages. Between 1300 and 1700, economic growth was only at 0.2 percent per year. Something growing at that rate requires 350 years to double; you can see that on the graph.

But since the 1870s, the amount of time that it’s taken for the standard of living to double has been more like 30 years. So what accounts for that incredible change?

Well, actually, it was the discovery, the exploration and even the exploitation of Americas that showed the Europeans that the pool of resources at their disposal could increase over time. It seems like an incredibly simple concept, but up until that moment, the Europeans felt that their pool of resources was fixed. That meant that if I wanted to prosper, you had to get poorer.

This discovery, that there were more resources available in the world, gave them trust in the future. Banks were born, and credit was invented in order to finance those adventures and enterprises, and this had a knock on effect on industry.

So in 1776, Adam Smith published arguably the most important book of all time regarding economics, and this was called The Wealth of Nations. He explained why some nations are poor and how wealthier nations fostered this belief in growth.

They encouraged business owners to reinvest profits back into their business. Instead of taking it out every year and keeping their businesses the same size, he said, well, once you and your family have eaten, take those excess profits, reinvest them back in the company, buy more capital equipment, hire more labor and your company will grow. You’ll create more profits that can be reinvested. The overall pie from which everyone eats is going to grow, and all of society will benefit.

Within a year of Smith coining the term ‘capitalism,’ the world had its first truly global generic technology for increasing productivity. This was James Watt’s steam engine.

It was initially applied in the coal mining industry, not to dig the coal out directly. In the U.K., the coal mines were flooded with water, so they couldn’t access much of the coal. They used the steam engine to pump the water out, giving them far more access to the coal seams.

They ended up with giant mountains of coal alongside each one of the mines, far too much, in fact, for the horses to cart away. So, someone had the genius idea of strapping a steam engine to a wagon, and they invented he railroad. They used this to take the coal and steam power over the next 100 years throughout Britain, and it became pervasive throughout all industries.

By the 1800s, in fact, steam was at the heart of all heavy industry in Britain, and all the factories looked like this.

Now, I’m going to describe the factory a little bit. At the bottom, buried underground in fact, you have the engine room; there’s a giant steam engine. Because it was burning coal, you always had a coal stack to let the smoke out. And in the factory itself, all of the equipment was organized vertically behind the engine room on three, four, five stories.

Now why was this? Because in order to access that power from that single engine, they needed to be as close as possible to that engine room, and that meant stacking them vertically.

There was a giant pulley with a leather belt, which drove shafts to give power to all of the equipment.

Here’s a picture, actually, of a factory from the 1800s. Isn’t it amazing? It’s chaotic, but it’s full of energy. Everything’s moving. Everything’s powered. And you can imagine the massive leap of productivity that came with all of this free movement.

In fact, that inflection point on that graph, that jump in productivity, was really directly due to steam power in manufacturing.

But for all its impact, this was an imperfect revolution. We all know the effect of burning coal on the atmosphere. It wasn’t a great place to be in the 1800s. And, of course, the one massive engine that was installed at the heart of these factories represented a kind of single point of failure. Plus, the leather belts were driving all of the equipment at the same speed, which isn’t great for flexibility.

And, as you can imagine, with all of the equipment tied to the same machine, I wasn’t really able to make really more than one type of product in one factory. So, very little flexibility.

Now, factories don’t look like that anymore, and the reason is this little guy. It looks pretty innocuous, doesn’t it? But it had the power to change everything.

It’s a model of the very first electrical motor, invented by a friend of ours, Werner Von Siemens. He invented this in 1866.

We now a lot about that period because Werner wrote a lot of letters. He wrote letters to his wife, which is something I don’t really understand – why didn’t he just talk to her? And, also a lot of letters to his brother, William, who was running Siemens U.K. at the time. And he wrote him one letter about his electro dynamo:

I believe that this small invention has the power to change everything, to revolutionize industry, to revolutionize Siemens and to change society for the better.

And he was absolutely correct. What he didn’t anticipate was just how long this adaptation would take. By 1900, four decades – forty years – after his invention, 95 percent of industry was still steam powered. And the few companies that had actually shifted to electrical power were swapping out steam motors one-for-one for the electrical motors.

They weren’t using the transformational potential of electricity; they were just installing great, big electrical motors in the place of the steam engines.

Now, this looks like a picture from a steam factory, right? But, it’s actually electrical-powered. It’s one of those early adopters of the big electrical engine using the same old leather belts to drive the equipment.

It wasn’t until the 1920s that the diffusion of the technology passed the 50 percent point. Why did it take so long?

Well, for the same reason that our customers don’t always buy the technology we pitch immediately, even if it is awesome. They want to see the technology mature; existing equipment has to be depreciated. Business processes get in the way of change.

It took 100 years for steam to become firmly established in industry, and 60 years for electricity. But once the shift started, it began unlocking major productivity gains as small electrical motors were used to drive individual machines, and the manufacturing process fundamentally changed.

More and more companies jumped on the bandwagon, and a kind of polarization occurred. The companies that didn’t move fast enough get left behind.

This is what we call the tipping point.

So here’s my first key message: It takes time for change to happen, but once you get to this tipping point it happens really quickly.

I like to think of a skiing analogy. Picture the slopes. It’s been snowing all season; it’s pretty late in the season now. It’s nice warm weather. The smart CEOs are down at the beach with their families. The laggards are still on the slopes. They paid for their season passes, and they’re going to use them. And as the temperature rises, they’re really happy skiing in their shirt sleeves until it all comes crashing down.

Let’s take a look at this video.

Now the fact that no rabbits were harmed in this movie is actually where the analogy breaks down, because in Industrial Revolutions, the laggards die. That has been proven time and time again.

Now, steam, electricity and automation are the three milestones or revolutions that have kept productivity increasing for 200 years. And Siemens has been at the forefront of each of those revolutions.

But since the 1970s, overall productivity growth has been dropping off. As you see, we’re now down at the levels we were in the 15, 1600s, and remember what that means for standard living improvements.

Why is this?

Well, there are numerous macroeconomic factors at play here, but one significant and surprising one is the consumer herself.

The Internet has provided transparency and choice for nearly 3 billion connected consumers. We want smarter products with microelectronics, semiconductors and embedded software. Think of the sophistication and quality of a family sedan in 2016, and compare it to one from the 1970s. There is no comparison.

But as products get smarter, their complexity increases. A modern car has more than 100 CPUs, more than 100 computers onboard, controlling everything from entertainment, internal comfort, ride dynamics, engine performance management.

You have to add to that incredible complexity. The ability that automotive companies provide to their customers to configure an almost infinite combination of colors, styles, accessories, engine performance enhancements, interior designs. With current manufacturing technology that hasn’t fundamentally changed since the 1950s, we really struggle to keep up in terms of productivity.

It’s almost as if productivity, flexibility and quality are three mutually exclusive options you have to decide between. And the more the market expects manufacturers to provide that flexibility, that individualization and quality – so, productivity suffers.

In 2011, the German government realized that if this continued, then their huge manufacturing base would soon hit a brick wall.

They launched Industry 4.0 precisely to find a solution to this challenge. They wanted to apply to manufacturing the same kind of digital technologies that were revolutionizing the business world and offer bespoke tailoring of these complex products at greater efficiency than they could offer today with mass production.

They weren’t interested in making small, incremental improvements. They wanted to change the paradigm completely. They wanted a huge leap in productivity. They were looking for a fourth Industrial Revolution.

Now the video you see here does a pretty good job of showing how this paradigm shift occurs, taking the fixed but highly automated lines that are in all automotive factories today and have been since Henry Ford first made the Model T, and turning the paradigm on its head: putting the intelligence of how a product should be made inside the product itself, and allowing that product to negotiate with far more flexible logistic systems, robotics, and having them collaborate with people to make that car, or that train or that aircraft.

Fortunately, Siemens was way ahead of the game. By 2011, we had already been working on our digitalization strategy for more than a decade. We had developed or had acquired many of the building blocks that would become our Digital Enterprise Software Suite: PLM, MES, automation, a collaboration platform, high-performance industrial networks, security.

Of course, we were aware that the market would require convincing references, and so our attention turned inwards to our own 300 manufacturing facilities.

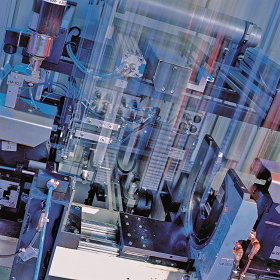

Today, the Amberg facility in Germany that makes SIMATIC switchgear and industrial computers is affectionately known as the “Industry 4.0 factory.” A lot has been said about it, but I think it’s worth looking again at some of the highlights.

It’s not a big factory, but it is fast. We make more than 1 million products a month – that’s one every second. Bang, bang, bang, bang. And these are complex products. Now normally, in order to be able to achieve this kind of productivity, a factory would have to concentrate on a very small number of products, would have to set everything up perfectly, would have to avoid any kind of disturbance or changeover.

But we understood that that was a thing of the past. We didn’t want to be that kind of factory. And so, we built flexibility into our business processes.

Today in Amberg, we offer more than 1,300 products to the market, all designed in NX, all managed in Teamcenter and all produced with SIMATIC on the factory floor. We offer these products to more than 60,000 different customers.

And, remarkably, we are able to provide customers with a guaranteed 24 hour lead time. That means you pick up the phone, you order a product and one day later, you have it. That is unprecedented, and it changed the paradigm of the industry.

Now, I’ve met many customers who are fast and flexible. And, what suffers is normally quality. But in Amberg, we do the seemingly impossible. We have a defect rate of just 11 – it’s now 11 – defects per million. That’s 99.9989 percent perfection. Every single product we make. Every single second.

So, how did we achieve this? Well, through digitalization, clearly. We create an entire digital twin of our whole value chain. That means designers, and engineers, and operators can collaborate within a completely virtual world designing the product, testing the product without creating physical prototypes.

We can design the factory, the equipment, the logistics systems.

We can push the virtual product and the virtual plant together in order to understand the most efficient production process.

We can simulate people. You know, there’s 1,200 people working in that factory. We have to simulate their movements, the way they interact with the product. We simulate the equipment, we simulate the logistics, until we’ve identified every potential bottleneck, every problem with manufacturability, and we’ve resolved all of those problems in the virtual world before we ever commit a resource in the real world.

Once that’s done, we publish the result. It’s called a bill of process; it’s a kind of blueprint. We publish it into the shop floor, and the MES takes that, and it guides every single one of our products around the factory. As you can see in the photo, each one of the products is sitting in its own little buggy.

So, unlike normal factories, where all the product flows in a very uniform way through the production facility, we use the bill of process to drive each product individually through the factory. And, 50 million conversations occur each day between the products and the smart equipment.

Each product understands which is the next production step that needs to occur. It reaches out to the equipment. It asks for the equipment with the right capabilities. And when it finds it, it asks the logistics system to route it there.

Once the operation is done, it’s able to test itself. If there’s a problem, it goes and finds someone to rework it, and it provides electronic work instructions using augmented reality to make sure that job is done correctly.

The result is speed, the result is flexibility and the result is unparalleled levels of quality.

Finally, we have a factory with no latency, no stockpiles, no wasted resources. We offer our customers individualized products with future-proof manufacturing.

Now this is the promise of Industry 4.0, and as part of the Siemens community, we are incredibly privileged to be able to talk to our customers about this with the knowledge that we’ve already done it. We can take our customers to see this, and we can then help them on their journey to becoming their own digital enterprise.

What’s more, we know that all of this learning is built into our own Digital Enterprise Software Suite. It’s the first and only digitalized portfolio that covers a manufacturer’s entire value chain.

Now, when we talk to our customers about digitalization, we show them Amberg, Cheng Du, Maserati, Rolls Royce – they understand the potential. But all too often, they say: you know what, this was great. We’re going to go back home. We’re going to create a committee; it’s going to be called “Vision 2030,” and we’ll get back to you when we’ve written some white papers.

We have to impress upon these customers that they have no time to wait, and we do this by going back in history.

Intel’s Gordon Moore famously predicted that the speed of semiconductors would double every 18 months. Now, everyone knows this rule. My kids know about Moore’s law. What they don’t understand is the power of this kind of exponential growth. We feel this is key to communicating the urgency of digitalization to our customers.

To illustrate the implication of Moore’s Law, we’re going to travel back in time to 6th century India. We’re going to go to the royal court, where a doctor, who’s invented the game of chess, is presenting his game to the emperor. The emperor is incredibly enamored by the game, and he wants to reward the doctor.

The doctor says, well all I want is rice for my family. I’d like you to put one grain of rice on the first square of the chess board, two on the second square, four on the third square and I’d like you to keep doubling that, please, on every square.

Now, you know this story. After 32 squares, halfway through the chess board, there was an incredible number of grains of rice – 4 billion. And, the emperor was starting to think he was being taken for a ride. But he wasn’t too worried. 4 billion grains of rice is about the annual production of one field in India at the time. People’s brains work linearly, so the emperor thought, well, by the time I get to the end of the chessboard, we’ll probably have doubled that number.

And that’s, of course, where he’s wrong. That’s where we enter the second half of the chessboard. The numbers get so large that logic breaks down. Things just get weird. In fact, at the end of the chessboard, on the 64th square, the number of grains of rice is so large I don’t even know what that means. It’s more than all the rice ever grown in the history of the world. If you took that number of grains of rice and piled it up, it would be larger than Mount Everest.

So, they killed the doctor for being such a smart aleck. But it’s a good illustration of the power of exponential growth.

What’s it got to do with digitalization?

Moore’s Law has held true since companies began buying IT in the late 50s, quietly doubling in power just like the rice on the chess board. Now, we entered the second half of the chess board for IT in 2006 – the same year the PlayStation 3 was launched with twice as much computing power as the world’s fastest computer from only a decade previously.

It was called ASCI Red. There was only one of them. It was owned by the U.S. government. It was enormous; it filled an entire warehouse. It was used to simulate nuclear explosions. And, just three squares later, every kid in America was blowing up aliens on his PlayStation 3 with twice as much power.

Since then, IT power has doubled another six times. That’s a 256 fold increase in processing capability over those nine years, and it’s brought us self-driving cars, autonomous robots and deep artificial intelligence.

Now, in the early 1900s, it was the new, agile companies capable of thinking differently and applying those smaller motors to individual machines that drove the shift to electrical power, and they’re the ones that rode the next wave of productivity and prosperity. All the big established companies that were heavily invested in the status quo just disappeared. If you look at the Fortune 500 before and after the first and second Industrial Revolution, you’ll see that the names changed every single time.

This is going to happen again with Industry 4.0. And this time, it’s going to be much faster. We don’t want our customers to disappear, so we use these anecdotes to sensitize them to the urgency at hand.

For digitalization, there’s no question that the time is now. And the CEOs who have left it this late should bear in mind Hemingway’s quote about how a man goes broke: very gradually, and then very suddenly.

Digitalization is coming, and it’s coming fast. And history shows us that during Industrial Revolutions, he who hesitates is lost. This is especially true in a digital world.

67 percent of manufacturers in the U.S. know they need to digitalize. They just don’t know how. Siemens and other visionary companies have already started our own journey, and we can show these other companies the way.

Most importantly, we cannot ask our customers to throw away their systems and start over in order to digitalize. We have proven that our open digitalization platform is able to provide revolutionary results through an evolutionary process, and unlock huge growth for our customers as they enter the fourth Industrial Revolution.

Thanks very much.