Are you ready for industrial-scale additive manufacturing?

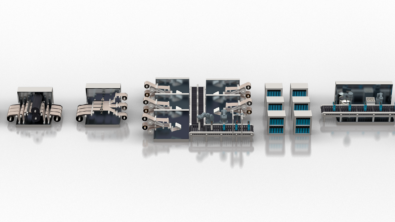

New technologies have revolutionized manufacturing, and one technology that’s changing how companies think of manufacturing is industrial-scale additive manufacturing, also known as ISAM.

ISAM allows for a myriad of capabilities not possible with traditional manufacturing methods. Companies can now build complex, customizable products once thought impossible. What’s more, process and efficiency are built into the equation to accentuate the benefits of this new technology.

The market is now at a place where you can do more than reinvent parts: you can reinvent the process.

In our new podcast series, Is Your Company Ready for Industrial-Scale Additive Manufacturing?, Dean Haehnel, director of marketing, and Robert Meshel, director of the Siemens Additive Manufacturing Network initiative, discuss ISAM’s capabilities in detail and offer insight into how a company can prepare for industrial-scale printing.

Haehnel and Meshel discuss how ISAM affects the entire business model and how you think of manufacturing, including what it means to reinvent your processes for complexity and customization. Moreover, it transitions to the materials used in manufacturing, reimagining products which couldn’t be created in the past.

The level of expectations for additive manufacturing in harnessing capabilities which redefine your business, its proficiency and level of achievement is also discussed.

The potential is enormous for ISAM. It’s an investment in the future which will soon be fully integrated into the manufacturing process. Analysts have estimated that the industry is currently worth an estimated $7 billion, with continued growth expected at 25 percent in the next five years.

It’s the purest manifestation of Industry 4.0 ― fully digital.

Other topics Haehnel and Meshel discuss in this podcast are:

• How ISAM differs from what manufacturers are currently doing;

• The benefits of additive manufacturing and how it will open up a new business model, including its multilevel capabilities and possibilities to create lightweight products with complex structures; and

• How to partner and collaborate with external entities to leverage their expertise.

The full podcast series is available on Soundcloud, Stitcher, and iTunes.

About the author

Blake Snodgrass is a writer for the Thought Leadership team in Siemens PLM Software, which supports several venues, including the Thought Leadership blog for the company. He speaks with experts in their field who provide compelling insight into innovative technologies affecting industries and how this can impact the future. Blake has a Bachelor of Arts degree in Mass Communications and more than 25 years of experience working for IT companies, with roles in technical writing, marketing communications, user-experience design and content development.