Smart machines, smart engineering

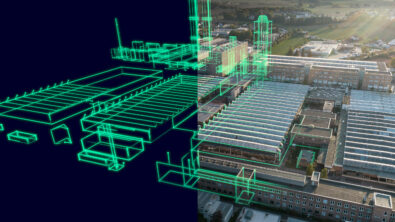

In the world of Internet of Things (IoT), Industry 4.0, and digital twin, smart machines need smart engineering. Technology is seeing manufacturing digitalized – smarter, connected, sophisticated machines.

Customers are demanding customization, complexity and speed as machines become more intelligent with the ability to do more automatically. Machines are available today that function autonomously and continuously, changing the contents of bottles and labels, all based on digital work instructions. Machines are projected to become part of an integrated production line – using sensors, connected over the internet, to provide real-time data on production progress and machine status.

Monitoring machine status

Machines will monitor status, temperature, hydraulic performance and pressure levels. They will also auto-flag anomalies for engineers to address problems before they escalate and become costly through malfunction. So, machine information will include a broader data ecosystem with several technologies: actuators, sensors, wireless video cameras and RFID readers with continuous data from the production line.

This information and analysis are cloud-based, providing operational intelligence for people and machines to make sound decisions. However, these innovations massively increase machine-building complexity because millions of lines of code are essential to control machines with advanced software.

Furthermore, manufacturers demand complexity in crucial markets like automobiles and consumer goods of customized products.

Looking to future technology, customers expect intuitive interfaces like touch-screen systems that require less training and allow more control over the machine. This scenario requires advanced software, which adds more complexity to machine design. The days of designing, building, and supplying a standard machine model with a long-life cycle are declining.

In addition, the changing safety standards and environmental agenda is a moving target. So, to comply with demands, machine configurations must change often. Furthermore, globalization increases margin pressure with the rise of the machine making lower cost economies. In response, we must manage the ever-growing increase in machine complexity, find efficiencies to cut costs, and be flexible by designing, developing and engineering machines to be more agile.

Building machines in a smarter way is the foundation of advanced engineering of a digital platform that hosts all project work, enabling collaboration across teams to store and catalog work to ensure an IP can be reused. Moving to an integrated system designed for the project lifecycle of machine design, machine builders can take essential steps to enhance production processes including: mechatronic design, engineering to order and virtual commissioning.

Learn more about these three differentiators.

Software solutions

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow.

Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram. Siemens Digital Industries Software – Where today meets tomorrow

Learn more about Smart Manufacturing in a recent sme.org article by Rahul Garg.

We always look forward to offering new perspectives on smart manufacturing, so stay tuned for an upcoming podcast series on this topic.