The Digital Enterprise: How unlocking your data accelerates digitalization

In today’s industrial landscape companies of all sizes and from all markets are learning to operate in an era characterized by rapid innovation and ceaseless improvement. Buyers in consumer and commercial markets demand products with cutting-edge capabilities, making products more complex than ever, and sparking intense competition amongst businesses. To meet the unrelenting pace of progress and ever-evolving customer needs, companies must not only weave sustainability, agility, and intelligence into their products, but into the very fabric of their organizational DNA.

Sustainability is no longer a bolt on. It has grown into a primary concern for companies around the world as business strategies and new regulations align to drive profitable sustainability initiatives that reduce the environmental impact across all industries. These trends have implications across the product and production lifecycle, and will drive changes in how companies design, test, manufacture, source, and recycle the products of the future. Our industrial activities have certainly contributed to the ongoing climate crisis. At the same time, the technological innovation being fostered in industry will also help create impactful solutions to help reduce carbon emissions, lower our resource usage, and safeguard the future of our planet.

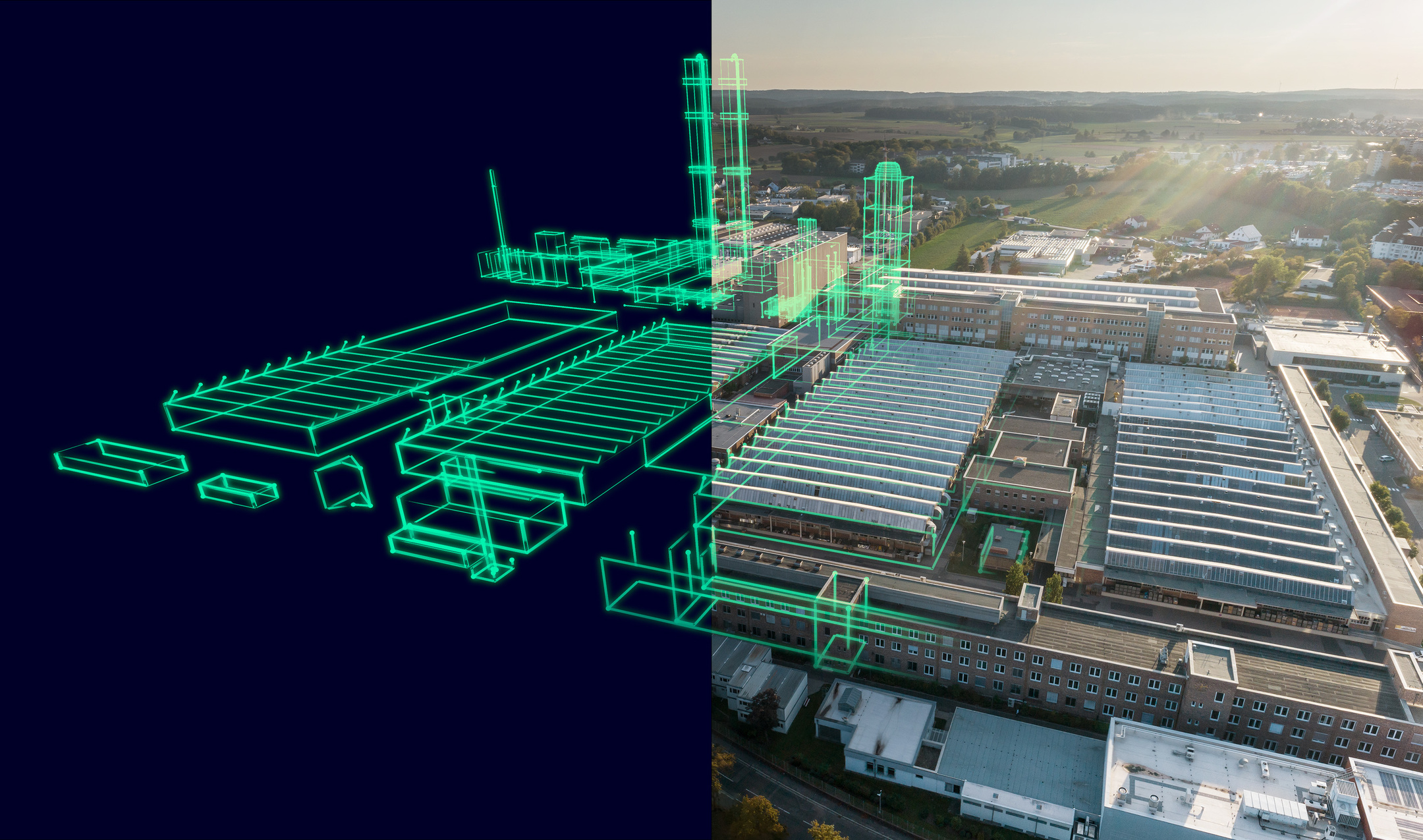

In the search for technology and engineering partners, only companies that can provide integrated software, automation, and services can help overcome the challenges of tomorrow by facilitating the creation of a digital transformation strategy. Digital transformation enables companies to combine the real and digital worlds, managing their businesses through both the real and virtual worlds.

This combining of real and digital unlocks a critical resource: data. Bringing these two worlds together enables the flow of data between all stakeholders involved in the development of a product or the production itself. Digitalization in this manner can also guide and support companies on their sustainability journeys, facilitating energy and resource efficiency, decarbonization, and the creation of a circular economy. In sum, it enables you to achieve more while using fewer resources.

As we move into the future, the ways in which data is generated, captured, and deployed will mean the difference between pulling ahead of the competition or being left behind. Those companies that can unlock their vast data resources will accelerate their transformation into Digital Enterprises and be positioned to quickly adapt to changing customer needs and market dynamics from product design to manufacturing to recycling and beyond.

Let the data flow

The digital journey starts by combining the real and digital worlds across the lifecycle for both product and production – design, realize, and optimize including the recycling at the product life end. The result is new flows of data between all the key areas for product and production, including engineering models, test results, materials, building processes, automation code, and more.

These can be considered as ‘horizontal’ flows of data that move from product development to production, between engineering domains and across functional groups. By enabling horizontal flows of data, companies can supercharge optimizing processes throughout the organization.

Horizontal flows of data enable clearer and faster communication between teams, supporting more effective and frequent collaboration especially across engineering domains that have traditionally operated in silos. And with the Digital Twin, engineers can also run multitudes of design iterations in quick succession to find optimal solutions in both product design and production planning. Now they can accelerate design cycles while reducing cross-domain integration issues.

But what about the other direction? What can vertical flows of data do for companies as they confront the challenges of tomorrow? In short, they can do quite a lot. We summarize the vertical movement of data with the phrase ‘IT/OT convergence’. At the highest level, such data flows connect executives, managers, and planners in the top floor directly with the day-to-day operations on the shop floor throughout the organization.

The convergence of information and operational technology (IT/OT) in recent years has been a catalyst for companies to build top floor to shop floor flows of data. IT/OT convergence enables companies to connect information and operations, increasing transparency and access to data across the product and production lifecycle and throughout the supply ecosystem. Companies can track production batches for quality and throughput while also gathering live production data from connected machines to enable faster reactions to quality issues and to drive optimizations in the production system.

Digital threads are extending further and further into supply chains and ecosystems, extending the reach of vertical data flows beyond the borders of a company’s own enterprise. Decision makers will have access to the most up-to-date logistics information on material delivery, production timelines, and even potential supply disruptions. Conclusions will therefore be reached using detailed and contemporaneous information, vastly improving confidence.

Becoming a Digital Enterprise with access to data will also help drive sustainability. Data is the key to creating more sustainable designs, improving energy consumption, becoming more energy efficient in the factory, driving decarbonization, and building the circular economies of the future. Rich data will give us greater insights on how to reuse materials, optimize the movement of materials and products, build sustainable supply chains, and more. In fact, recent analysis has found that 80% of a product’s sustainability performance is determined during the design stage and the decisions made therein.

Transform faster through data

Through digital transformation, companies can take full advantage of their most precious resource—data. The result is greater transparency, traceability, and the ability to create a closed loop between product development, production, and optimization. It is how industrial companies can become more resilient to future disruptions while achieving greater agility in their processes to drive efficiency and flexibility. The result will be more innovative and sustainable products that will delight customers.

This transformation must happen faster and faster for companies to keep up with the pace of innovation and the competition. For that, they can partner with us and our Siemens Xcelerator business platform.

Essentially, Siemens Xcelerator grants access to hardware, software, vast knowhow, and established partner systems. Working together, companies can connect the data that is already within the organization, leading to a more holistic understanding of operations across the product and production lifecycle, and from top floor to shop floor. As a result, they can become a Digital Enterprise faster than ever with Siemens Xcelerator.

To learn more, visit us at www.siemens.com/digital-enterprise