Are your alternative parts well validated before release

Alternative parts are a commonly known concept in electronic industry. They are used as a substitute for when the primary part or original part is in shortage. Alternative parts are also useful for reducing overall costs when the price of a primary part is relatively high.

In alternate part selection, many aspects need to be considered: electrical function, physically fit, supply chain flexibility, cost, etc. Every aspect is important during alternative part selection, but realistically, electrical and physical fit are the main prerequisites when choosing a new alternative part.

Alternate parts are commonly selected from different vendors, because different vendors provide more resilience to your supply chain, but exactly how validation of these alternative parts occurs in comparison to the original part before you add it to your AML(Approved Material List) is a good topic to discuss.

A poorly validated alternate part can cause potential assembly issues to the manufacturing process. Some critical issues may even force the production to stop, that would impact the product delivery and profit loss.

Physical validations to alternative parts

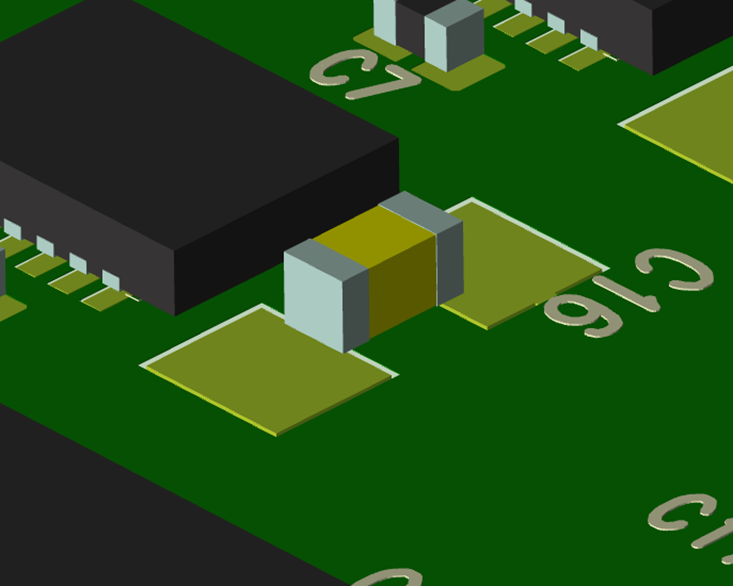

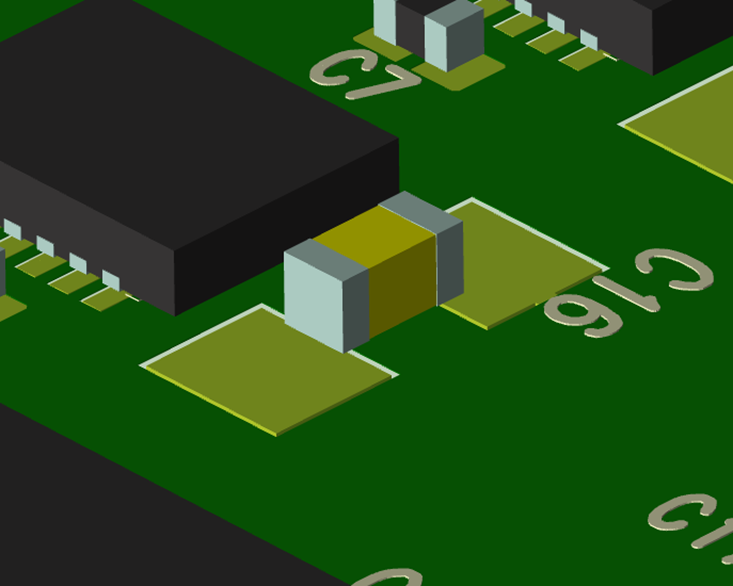

When new alternative parts are selected by your design engineer, the physical fit is one of the key features that you need take into consideration. Designers need to make sure the new alternative part not only fit well to your ECAD footprint, but also fits within existing PCB designs.

Here are some key points during physical validations:

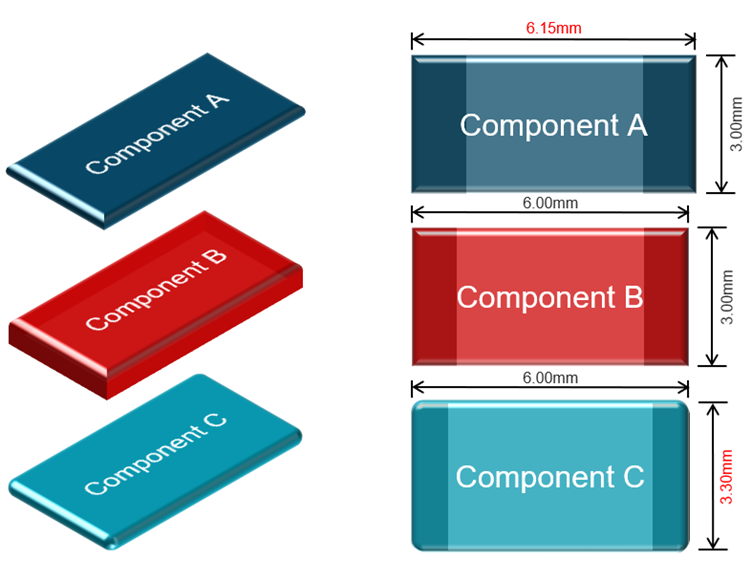

Component Size

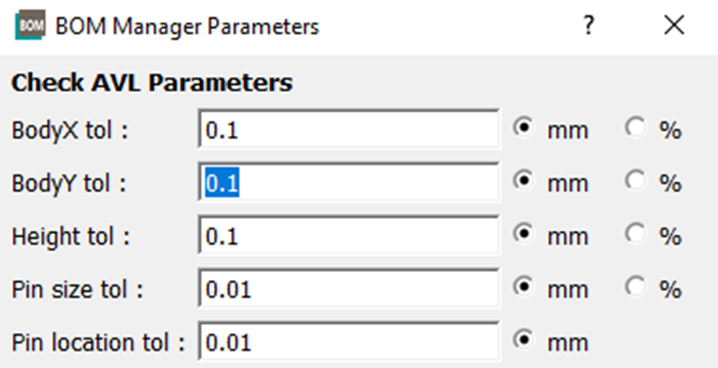

The size of chosen alternate parts should remain similar in length, width and height to the original part. Typically, an absolute or relative(by percentage) tolerance is used to evaluate if the alternative part is fit to use.

Pin Count

Same count of pins to the original part is mandatory.

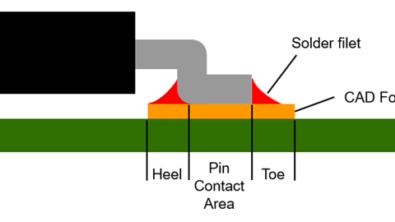

Pin Size and Location

Pin location and pin size are both also important when keeping the pin contact area within the toeprint of the original ECAD library. In addition, IPC standards are used to evaluate if the pin fits well with the original toeprint.