ODB++Process and Coping with Supply Chain Uncertainty

As the electronics manufacturing sector struggles to rebound from the Coronavirus pandemic and its effect on vulnerable global supply chains, the promise of ODB++Process (“ODB++P”) is the ability to rapidly shift production from location to location, without having to re-program for a different set of machines – thus ensuring business continuity.

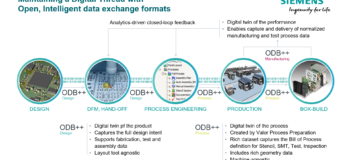

ODB++Process is the third and final pillar of the ODB++ data exchange format, which now provides an end-to-end “digital twin” of the Industry 4.0 design-to-production information flow:

- ODB++Design: A complete data representation of product design.

- ODB++Process: The design data, converted into a format that can be imported for use by any production machine.

- ODB++Manufacturing: A data aggregation of all shop-floor events that can be utilized by other machines or by performance-tracking software.

Standardizing data exchange in PCB assembly

The ODB++Process model simplifies and standardizes the exchange of process engineering information among machines on the shop floor – reducing production downtime and enhancing operational efficiency.

ODB++Process file generation is a standard feature of the Valor® Process Preparation process engineering tool from Siemens. It enables the open exchange of intelligent assembly process engineering data between Process Preparation and any shop-floor machine that supports the ODB++Process format. After importing the file, the machine’s software can perform a final process optimization and execute the program – without human intervention.

Want to learn more about ODB++Process? In our “Introducing ODB++Process” Webinar we introduce the new exchange format and demonstrate how it improves the agility and flexibility of electronics manufacturers as they continue to cope with supply chain uncertainty.