What is Shift Left?

“Shift Left” is a method used in the design process in a virtual environment in which data is used to solve issues earlier in the process — hence, shifting problem solving to the “left” on the timeline. This concept started in the electronics software industry due to the rising cost of design respins, and has expanded into other industries including manufacturing where companies are using data to address concerns long before the manufacturing stage commences. The Shift Left method helps companies design the products and processes faster and with greater cost efficiency.

Think about industries like automotive and aerospace and defense where companies often still rely on a mix of manual processes and legacy tools for manufacturing. There is obviously value in increasing automation within these factories, but in many cases there is a fear that adopting these processes would either be too burdensome or that it would interfere with current production, or both.

Like any industry, these manufacturers face increasing pressure to reduce costs, improve cycle time and boost product quality while maintaining the flexibility to accommodate design changes and customizations. On top of that, companies must also ensure a safe work environment within the factory.

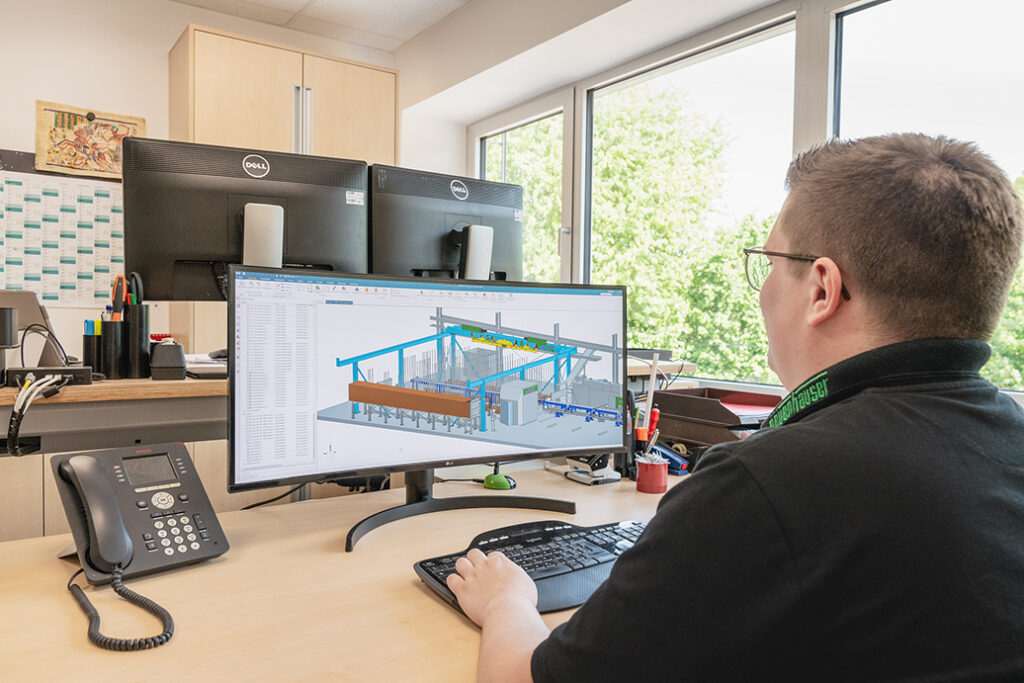

When companies implement digitalization initiatives, they can achieve the Shift Left strategy of the intelligent manufacturing approach and have a better understanding of their manufacturing process. By creating a digital twin of an entire manufacturing facility down to individual assembly lines and machines, engineers are Shifting Left their troubleshooting, since they can now analyze their processes for errors and identify any areas of optimization before facility operations ever begin.

Shift Left: Using data insights early

How are manufacturers saving millions? By harnessing the virtual testing capabilities from the digital twin. Engineers can gather manufacturing data very early on in the manufacturing planning process. This helps save money, speeds up validation and reduces the risk of operational failure.

Because the digital twin can virtually build and analyze manufacturing processes, projects are completed more quickly, with greater efficiency, higher quality and better performance.

This strategy translates into real value for companies — those who Shift Left can save millions of dollars because they can rework design and manufacturing, and even create maintenance schedules, before ever building the production lines. Pinpointing potential issues early within the virtual environment enables organizations to deliver higher quality products on budget and schedule.

Siemens Xcelerator software for industry and Shift Left strategy

So, how do you accommodate design changes, increased customizations and forecasting costs?

With the Siemens Xcelerator software for industry, companies can utilize the comprehensive digital twin to include physical and virtual sensors.

The physical sensors collect diagnostic and environmental conditions of a product through manufacturing, delivery, and usage and continually feed updated data into the simulation models.

Meanwhile, the virtual sensors employ data from physical understanding and models enabling closed-loop optimization between design, manufacturing and performance, all of which rely on the models created in the digital twin to provide more information.

Artificial intelligence and machine learning technology can process the continuous amount of data and help detect issues early on as data is brought back into the digital twin. The ability to discover issues in the design phase via simulation and virtual commissioning, as opposed to waiting until manufacturing, is what the Shift Left strategy is all about.

With the Siemens Xcelerator software for industry, companies are realizing the benefits of a Shift Left strategy as ways to better compete while creating higher quality products.

Discover more about the Comprehensive Digital Twin.

Click here to learn more about how you can use the Shift Left method to create digital prototypes and accelerate your design process.

Learn more about Siemens Xcelerator.