Northrop Grumman collaborates with Siemens to further humanity’s reach for the stars

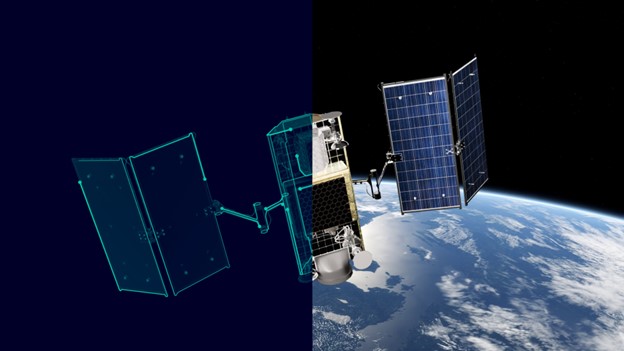

Headquartered in Dulles, Virginia, Northrop Grumman is a leading global aerospace and defense technology company that helps connect and protect the world. Their unique solutions help push the boundaries of human exploration across the universe. Northrop Grumman uses Siemens Xcelerator to lead a digital transformation of advanced space engineering processes.

NASA’s Habitation and Logistics Outpost (HALO) and its Lunar Gateway will be a staging point for long-term exploration of the Moon and destinations beyond. HALO builds on Northrop Grumman’s Cygnus spacecraft. These megaprojects involve NASA, Northrop Grumman, SpaceX, and hundreds of other private companies along with international space agencies from Europe, Japan and Canada.

Siemens has the vision and the suite of tools that allow us to move quickly into digitalization and advanced engineering simulation. We hope to continue to grow along with Siemens as a partner.

Dr. Tom Stoumbos, Simulation & Test leader, Northrop Grumman

The importance of the Siemens Xcelerator business digital platform

Northrop Grumman counts on the Siemens Xcelerator business digital platform of software, hardware and services, including Simcenter™ software for spacecraft performance engineering, to accelerate development, manage complexity, share large amounts of data among partners and suppliers, and improve project efficiency.

Dr. Tom Stoumbos, simulation and test leader is one of the pioneers driving the digital transformation at Northrop Grumman. A long-time supporter of digital transformation, agile simulation, virtual testing and industry-academic partnerships, Stoumbos and his team realize that leveraging simulation and data analytics is key to succeeding in space exploration. “Siemens has done a tremendous job bringing all these tools together into what is now the Siemens Xcelerator business platform. It is priceless that we can work in the digital realm with proper design analyses, close connections to the hardware we design and properly analyze and control mission requirements,” says Stoumbos.

Stoumbos and his team work on space vehicle designs that have stringent requirements because they are exposed to extreme thermal, mechanical, dynamic, and vibroacoustic environments during handling, launch, and separation as well as mission operations, analysis, design optimization and testing. Examining all this presents a variety of challenges for mission design and lunar exploration projects.

The team also counts on Siemens Xcelerator solutions, like Teamcenter® simulation software, to keep the digital thread running accurately throughout complex processes as well as other advanced engineering tools, including Simcenter Testlab™ software, Simcenter 3D, Simcenter Nastran, Simcenter Amesim™ software, the Simcenter Multimech™ platform, and HEEDS™ software for design of experiments, which are all part of Siemens Xcelerator. Dr. Stoumbos affirms, “We can execute solvers in parallel and optimize our products with HEEDS. Using HEEDS design of experiments has been invaluable in improving the efficiency of our analytical process. It can easily save 30 to 50 percent of our analysis time.”

Accelerating the design process

To accelerate the design process internally, the team has worked out its own multidisciplinary structural analysis and design optimization (MSADO) framework to balance attributes for missions, like launch vehicle vibration loads, orbital thermal heating, and acoustics with numerous design constraints. The framework is used to determine structural interactions with different orbital environments when designing complex space systems for deep-space satellite missions. Recently, the MSADO framework has been extended to cooperative space logistics and in-orbit satellite servicing missions. These are complex missions that include elaborate robotic systems and mission-critical docking systems.

The HALO design has successfully undergone preliminary and critical design reviews, one of a series of checkpoints for complex engineering projects. A multifaceted and multigenerational team will eventually bring HALO to life at Northrop Grumman’s Gilbert Arizona facility, which can tap into its space systems production and integration experience to prepare the space module for launch.

According to Dr. Stoumbos “In a decade or two, we have gone from designing communication satellites to developing complex robotic systems for servicing missions up in space and moving toward a digital twin for future space vehicles,” says Stoumbos. “That is an incredible pace of innovation. Siemens has the vision and the suite of tools that allow us to move quickly into digitalization and advanced engineering simulation. We hope to continue to grow along with Siemens as a partner.”

To learn more about Northop Grumman’s collaboration with Siemens Xcelerator, read the case study, “Automating the design space exploration process to reduce analysis time by 30 to 50 percent.”