Cox Marine: A digital transformation story

Salmon farmers in the Norwegian fjords or islanders in the Maldives who drive Zodiac boats to work can easily assess the massive, market-changing advantages of a high-powered, fuel-efficient, cleaner V8 diesel outboard engine.

Cox Marine, a British startup eager to revolutionize the outboard engine industry, is changing the game. By taking a digitalization approach, their first product, the CXO300 outboard engine, packed a punch yet boasted 25 percent more fuel efficiency and was cleaner than most other outboards on the market.

Not only were Cox Marine developing new outboard motors, but they were developing a business. As such, they looked holistically at the company and reinvented the service model to accommodate their network of 200 dealers and representation in 100 countries.

The challenges they faced were plenty. As a small startup, they had to enter a highly-competitive marketplace with both a product and a matching business model. Part of that meant their team was tasked with designing and engineering an outboard engine that was more fuel-efficient while also being high-performance, more durable and cleaner.

To accomplish this, they would need to integrate the right digitalization tools to succeed in both product development and to support a growing international business model.

Startups often have the benefits of being agile and flexible but can be burdened with the massive costs of technology. It was critical they had options that could scale to their needs when they needed it.

To accomplish their goals, they went with the digital transformation approach.

“We had to make something as small and light as a car engine, but as strong and robust as a big truck engine. Software plays a huge role in understanding how to optimize and design structures. There are so many elements to consider.”

Joel Reid, Global Sales Director Cox Marine

Digital transformation keys to success

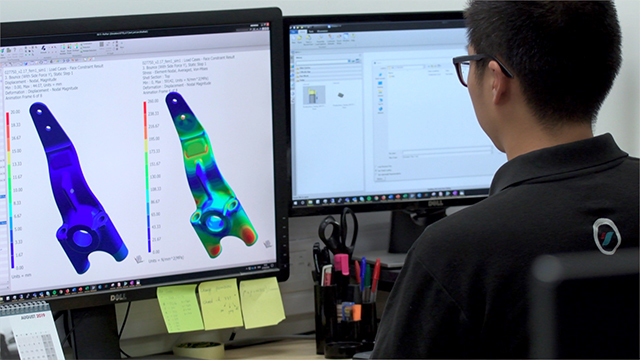

This is where digitalization allows them to compete instantly. Relying on digitalization tools, such as Teamcenter, NX and Simcenter from the Siemens Xcelerator portfolio, Cox Marine ensured its teams could collaborate in real-time, utilize cross-domain engineering and work in the realm of a comprehensive digital twin combining the real world and the digital world.

The comprehensive digital twin was critical to all kinds of design decisions. With advanced performance predictions, engineers could quickly try out concepts for feasibility studies and model parts for effectiveness. They could then tweak the model virtually to see how a design change might affect performance criteria and troubleshoot issues on the prototype.

Simulation software from Siemens Xcelerator, for example, gave Cox Marine answers that used to take months to retrieve in a matter of hours.

They also aim to fully use cloud services to perform data analytics such as engine performance statistics, revenue savings, real-time maintenance information and other predictive diagnostics, to optimize performance and service.

“We were able to build a much bigger and comprehensive organization to deal with the mammoth task of not just developing a diesel outboard as a product, but also developing an organization that can manage global demand, global services and volume manufacturing.”

Joel Reid, Global Sales Director Cox Marine

OnePLM: a digital transformation partner

How did a startup like Cox Marine get the whole process up and running? They counted on Siemens Solution Partner OnePLM, a recognized Smart Expert partner, to help implement the right tools at the right time and to bridge the digital backbone and ecosystem into the company’s ERP and production solutions properly.

OnePLM experts were onsite regularly, making sure that the Siemens Xcelerator solutions were improving and enhancing operations at Cox Marine.

Learn more about this success story by reading the full case study: British startup Cox Marine ready to revolutionize the outboard engine industry thanks to digitalization.