Schuster Mechanical improves machine shop productivity with Zel X

Table of Contents

In the northern suburb of Metro Detroit resides a former CNC programmer at a major automotive company: Bob Schuster, and the story behind his machine shop masterpiece, Schuster Mechanical. Specializing in automotive test equipment, Schuster Mechanical is a relatively small but very successful part manufacturing business.

Who is Bob Schuster?

Bob spent most of his career at General Motors (GM) as an apprentice metal model maker, which was his first taste of manufacturing, and over time, CNC machining came into the equation. After a few successful decades of his career, Schuster took a great interest in computer-aided manufacturing (CAM) and CNC technologies and eventually left GM with a wealth of manufacturing knowledge that would unknowingly fuel his future business endeavors. After Schuster left GM, he quickly discovered his entrepreneurial interests. He found himself immersed in a whirlwind of manufacturing activity —from mentoring high school robotics teams to launching his own company, all while balancing his passion for machining simultaneously.

The evolution of Schuster Mechanical

Schuster Mechanical became the canvas for Bob’s insatiable curiosity, where he could explore the latest trends in part manufacturing. Armed with a CNC machine and 3D printers, he was ready to tackle any challenge that came his way. Staying up to date on the latest digital manufacturing technologies wasn’t just about keeping up with the times — it was about positioning himself to seize opportunities, like the chance to work with major automotive giants again.

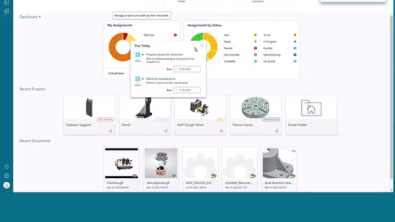

As the owner of Schuster Mechanical, Bob realized that even with his deep part manufacturing expertise and cutting-edge machinery, he needed a digital solution as Schuster Mechanical faced its own set of operational challenges. That is when Bob discovered the tangible benefits of Siemens cloud-based machine shop management software Zel X. He saw opportunities to run his shop more efficiently by optimizing manufacturing operations and streamlining collaboration with his customers. Doing so allowed him to manage the manufacturing data, coordinate with clients, optimize machining operations with fewer revisions, and stay organized all while perfecting the entrepreneurship edge. Zel X helped boost Schuster’s manufacturing operations, by enhancing productivity and ensuring higher part quality.

With Zel X, not only do you can do some cutter path and manufacturing, but you’re capturing the manufacturing process. You’re communicating with people, capturing steps, capturing drawings. It’s a nice way of being organized and reusing the work that you’ve done in the past. I like the fact that you can do cloud organization. – Bob Schuster, owner of Schuster Mechanical

Embracing digitalization to power machine shop efficiency

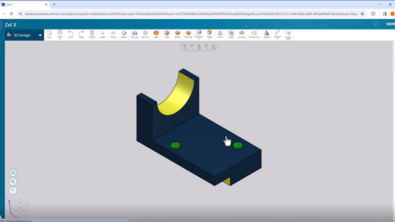

As an early adopter of Zel X software, Bob witnessed firsthand the power of cloud-based management solutions. With its intuitive interface and robust features, Zel X maximized how Schuster Mechanical operated, freeing him to focus on what truly mattered – the CAD and CAM work to machine high-quality parts. Zel X helped him simplify the quoting processes and facilitate seamless collaboration with customers, making his machining more competitive. With Zel X, Bob uses its lightweight computer-aided manufacturing (CAM) system to program simple parts and make his CNC operations using Zel X Shop Operations. It helped him to capture the manufacturing process, communicate with clients, capture drawings, and reuse the job data from repeatable jobs with his customers.

In the end, the Schuster Mechanical success story with Zel X is a testament to the era of digitalization and the power of Siemens Zel X software. By embracing Siemens’ cloud-based machine shop management solution, accessible on any device, Bob not only addressed his organizational needs but also forged direct collaborations with his customers, ultimately making his small shop more competitive in the industry.

About Siemens Zel X

Built on established Siemens Xcelerator platform technologies, Zel X allows users to easily interact with other companies using Siemens software and allow seamless scalability beyond Zel X. Users can maintain their design data and leverage it across the entirety of the portfolio, including NX Design, NX Manufacturing and Simcenter 3D.

Siemens Xcelerator is a comprehensive, integrated portfolio of software, services and application development platform designed to help companies become digital enterprises. Zel X and other cloud-based solutions are available via Siemens Xcelerator as a Service to make digital transformation happen faster.

Learn more about Zel X

Learn more about Zel X, click here.

Ready to try Zel X? Click here for a free 30-day trial.